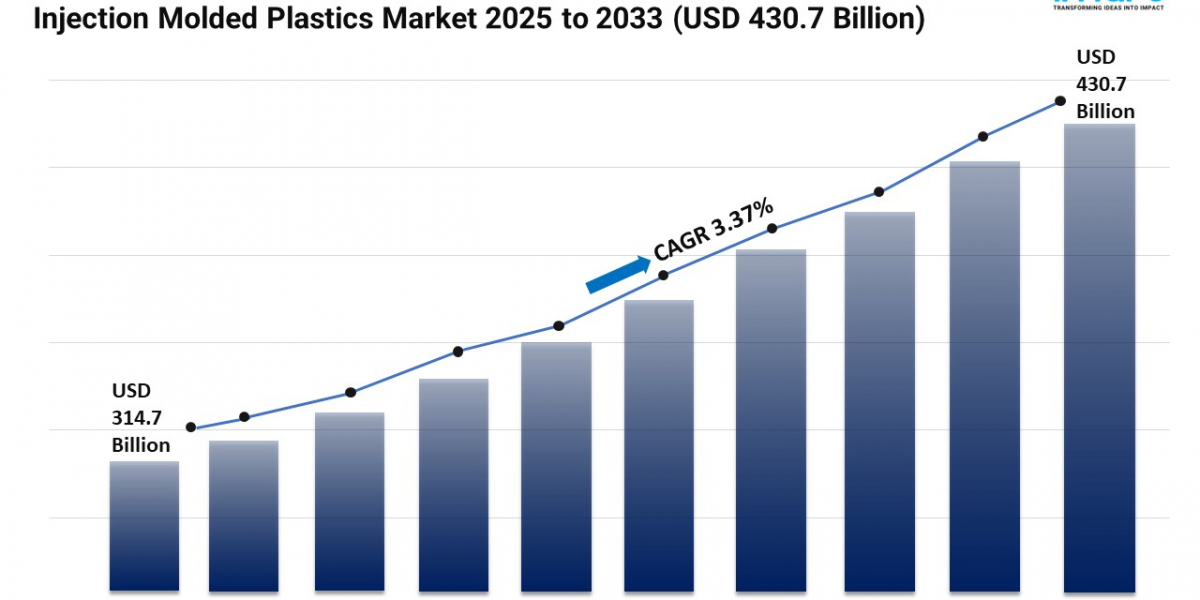

IMARC Group's report titled “Injection Molded Plastics Market Report by Raw Material (Polypropylene (PP), Acrylonitrile Butadiene Styrene (ABS), High-Density Polyethylene (HDPE), Polystyrene (PS), and Others), Application (Packaging, Consumables and Electronics, Automotive and Transportation, Building and Construction, Medical, and Others), and Region 2025-2033” The global injection molded plastics market size reached USD 314.7 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 430.7 Billion by 2033, exhibiting a growth rate (CAGR) of 3.37% during 2025-2033.

Factors Affecting the Growth of the Injection Molded Plastics Industry:

- Increasing Demand Across End-Use Industries:

Injection molded plastics are widely used in a variety of fields including automotive, packaging, healthcare, electronics, consumer products, building and many other fields. Through injection molding, plastics can be easily integrated into many components and products in these industries which can include car seats, electronic shrink wrap, bundling cans and even medical devices. In addition, sectors such as automotive and aerospace have seen a greater focus on lightweighting strategies for reducing emissions, improved fuel economy and improved performance. Lightweighting is another benefit of injection molded plastics as it gives manufacturers the opportunity to reduce the weight of the product compared to traditional product materials such as metal – all of this can be accomplished without any degradation in the strength or performance of the item.

- Product Innovation and Varieties:

Advances in injection molding machines and equipment have greatly enhanced the performance of injection molding with respect to speed, accuracy and efficiency. The widespread use of high performance hydraulic and pneumatics control, servos, robots, smart machinery through computers means increased cycle times, shaft tolerances and throughput, resulting in overall productivity and reductions in manufacturing costs. Additionally, robotics and automated assembly techniques are adopted to meet the requirement of injection molding operations, reduce labor costs and ensure standardized quality. Other tasks such as part removal, inspection for quality and packaging are also performed by robotic systems to ensure that the system runs virtually with limited interruptions.

- Expansion of Packaging Industry:

The packaging industry is enjoying continuous growth, growth factors include population growth, increased urbanization, changes in consumers' behavior and increased e-commerce activities. While the variety and sales of packaged foods, beverages, pharmaceuticals, personal care products and other consumer goods are constantly growing, the same can be said for the need for convenient and economical methods of packaging. However, injection molding plastics gives an added advantage of flexibility and the ability to make small variations which is very important in packing industries. Key players can produce a wide range of packaging products including bottles, containers, caps, closures, trays and blister packs with different shapes, sizes, colors and features to meet the specific needs of different products and brands.

Request for a sample copy of this report: https://www.imarcgroup.com/injection-molded-plastics-market/requestsample

Leading Companies Operating in the Global Injection Molded Plastics Industry:

- BASF SE

- Berry Global Inc.

- Chevron Phillips Chemical Company LLC

- Dow Inc.

- Eastman Chemical Company

- ExxonMobil Corporation

- Heppner Molds Inc.

- Huntsman International LLC

- Ineos Group Ltd

- LyondellBasell Industries N.V.

- Mitsubishi Chemical Corporation

- Rutland Plastics Limited and Saudi Basic Industries Corporation.

Injection Molded Plastics Market Report Segmentation:

By Raw Material:

- Polypropylene (PP)

- Acrylonitrile Butadiene Styrene (ABS)

- High-Density Polyethylene (HDPE)

- Polystyrene (PS)

- Others

Polypropylene (PP) represents the largest segment due to its versatile properties and wide-ranging applications across various industries.

By Application:

- Packaging

- Consumables and Electronics

- Automotive and Transportation

- Building and Construction

- Medical

- Others

Packaging accounts for the majority of the market share owing to the heightened awareness of environmental sustainability.

Regional Insights:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Asia-Pacific enjoys the leading position in the injection molded plastics market on account of favorable government policies, such as incentives for foreign investment and initiatives to promote manufacturing.

Global Injection Molded Plastics Market Trends:

The adoption of Industry 4.0 principles and smart manufacturing technologies in injection molding facilities has made real-time monitoring, data analysis, and predictive maintenance possible. Internet of Things (IoT) sensors, cloud computing, and machine learning (ML) algorithms optimize equipment performance, prevent downtime, and improve overall efficiency, thereby increasing productivity and reducing production costs.

Additionally, with the rise in environmental concerns and regulations, lightweight and durable materials are being preferred over traditional materials such as metal and glass. Injection molded plastics offer a lightweight alternative, which reduces fuel consumption in transportation and reduces carbon emissions.

About Us

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact US:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145