Global Zero Friction Coatings Market Statistics: USD 1,481.5 Million Value by 2033

Summary:

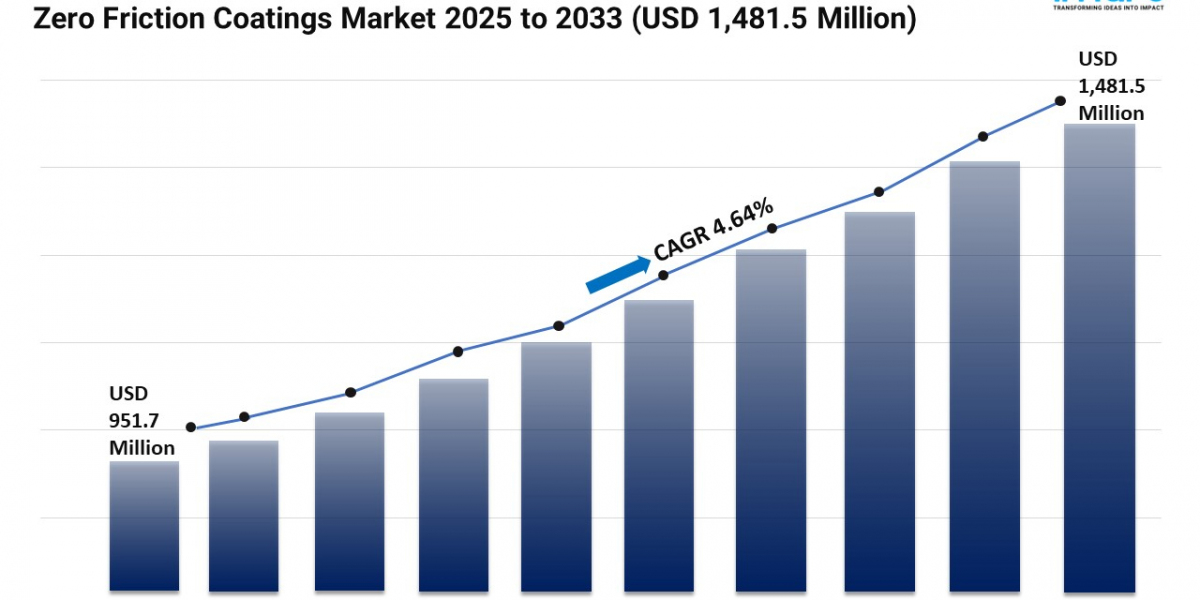

- The global zero friction coatings market size reached USD 951.7 Million in 2024.

- The market is expected to reach USD 1,481.5 Million by 2033, exhibiting a growth rate (CAGR) of 4.64% during 2025–2033.

- Asia Pacific leads the market, accounting for the largest zero friction coatings market share.

- Molybdenum disulfide accounts for the majority of the market share in the type segment as it allows for easy shearing and provides low interlayer friction.

- Solvent-based coatings hold the largest share in the zero friction coatings industry.

- Automation and transportation remain a dominant segment in the market due to the increasing focus on enhancing fuel efficiency, reducing wear and tear, and improving overall vehicle performance.

- The rising demand in the automotive and aerospace industries is a primary driver of the zero friction coatings market.

- Advancements in coating technologies and the increasing industrial automation are reshaping the zero friction coatings market.

Industry Trends and Drivers:

Growing Demand in Automotive and Aerospace Industries:

Many industries today such as automotive and aerospace industries rely on zero friction coatings. It’s used to enhance performance and increase fuel usage. In cars, energy dissipation and wear prevail due to friction in the engine, the transmission, bearings, etc. Zero friction coatings reduced this friction. This results to higher productivity, less fuel consumption and long lasting parts on the machines. Likewise, the aerospace industry must eliminate the friction to achieve better fuel economy, lower operational and maintenance costs, and increase safety. This is important for any components if they are going to be operated under severe conditions. An increase in electrification of new vehicles as well as progressive efficiency improvements in new aircraft is driving the need for friction reduction. This trend is generating a positive market attitude.

- Rising Industrial Automation:

The growth in industrial automation requirement is spurring the need for zero friction coatings. This is so especially with factories having many and complicated mechanical systems that move. Computerized systems require high degrees of accuracy and low down time. The need to avoid wear, increase efficiency and increase the life span of the machines critically demands elimination of friction. Robotics and packing industries are some of the industries where these coatings are applied. Here, facilities are in constant motion… They cause it to run smoothly with little need for frequent overhauls. Currently firms are spending more on these technologies to increase efficiency and accuracy. In areas of semiconductors and pharma production, these coatings are critical. It helps the companies to keep the quality of their products.

- Advancements in Coating Technologies:

The eras of materials science and nanotechnology are in the process of supercharging zero friction coatings. These coatings are now more efficient, harder wearing, and more versatile. New developments in nanotechnology such as nano-coatings and composite improve their ability to oppose wear, high temperatures and corrosion. This make them useful in sectors which include aerospace, automobile and heavy equipments. These progress guarantees that the coatings will withstand difficult conditions with little friction. Also, new methods of applying AI such as thermal spray and chemical vapor deposition (CVD) expand compatible surfaces. Certainly, they include metals, ceramics as well as polymers.

Request for a sample copy of this report: https://www.imarcgroup.com/zero-friction-coatings-market/requestsample

Zero Friction Coatings Market Report Segmentation:

Breakup By Type:

- Polytetrafluoroethylene

- Molybdenum Disulfide

- Others

Molybdenum disulfide account for the majority of shares as it allows for easy shearing and provides low interlayer friction.

Breakup By Formulation:

- Solvent-Based Coatings

- Water-Based Coatings

- Powder Coatings

Solvent-based coatings dominate the market on account of their ability to act as a carrier for the active ingredients and allow for smooth and consistent coating deposition on various surfaces.

Breakup By End Use:

- Automobile and Transportation

- Aerospace

- General Engineering

- Food and Healthcare

- Energy

- Others

Automation and transportation represent the majority of shares due to the rising focus on enhancing fuel efficiency, reducing wear and tear, and improving overall vehicle performance.

Breakup By Region:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Asia Pacific enjoys the leading position owing to a large market for zero friction coatings driven by the increasing demand for high-performance coatings to enhance efficiency.

Top Zero Friction Coatings Market Leaders:

The zero friction coatings market research report outlines a detailed analysis of the competitive landscape, offering in-depth profiles of major companies. Some of the key players in the market are:

- AFT Fluorotec Limited

- ASV Multichemie Private Limited

- Bechem

- DuPont de Nemours Inc.

- Endura Coatings

- GMM Coatings Private Limited

- IKV Tribology Ltd.

- Poeton Industries Ltd.

- Sandwell UK Ltd.

- Vitracoat Inc.

Note: If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1–631–791–1145