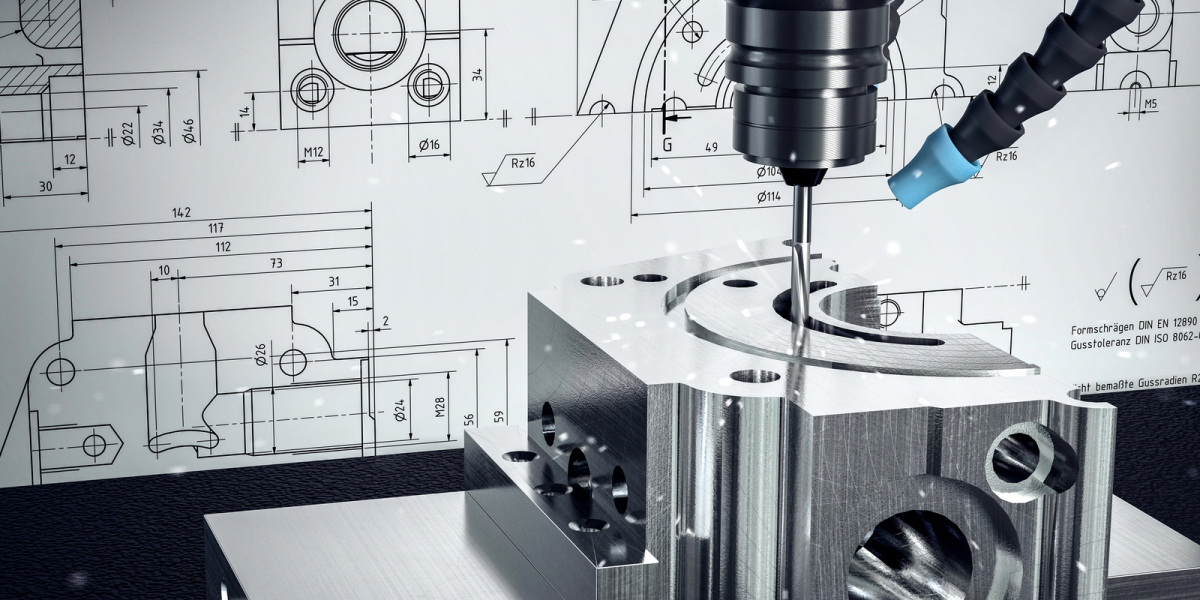

CNC Prototyping Service is essential for custom product development, enabling manufacturers to create accurate, functional prototypes with high precision. By using computer-controlled machining, this service transforms digital designs into physical products, supporting various industries such as automotive, aerospace, medical, and consumer electronics. Here’s how CNC Prototyping Service enhances custom product development:

1. Rapid Design Validation

CNC Prototyping Service allows product developers to quickly create prototypes for design validation. The ability to produce components with exact specifications helps identify design flaws, reducing costly errors in later production stages. This accelerates the development process and shortens time-to-market.

2. High Precision and Accuracy

CNC machines produce prototypes with tight tolerances and complex geometries. Their ability to maintain dimensional accuracy ensures that every component meets the required specifications, making CNC Prototyping Service ideal for industries demanding precision-engineered parts.

3. Material Versatility

CNC Prototyping supports a wide range of materials, including metals like aluminum, steel, and titanium, as well as plastics such as ABS, POM, and acrylic. This versatility allows developers to select materials that closely match the properties of the final product for functional testing and evaluation.

4. Customization and Design Flexibility

The CNC Prototyping process supports creating custom parts with intricate designs. Whether it involves unique shapes, internal cavities, or detailed features, CNC machining ensures the parts are tailored to meet specific product development needs.

5. Cost-Effective Iteration

Producing prototypes using CNC machining is cost-effective, especially for low-volume production runs. The ability to create and adjust prototypes quickly allows manufacturers to test multiple design iterations without incurring significant expenses, reducing the overall cost of product development.

6. Functional Testing and Performance Evaluation

CNC Prototyping Service enables the creation of functional prototypes that can undergo real-world testing. Developers can assess factors such as durability, performance, and usability, ensuring the final product meets industry standards and customer expectations.

7. Accelerated Product Launches

By providing fast and reliable prototype production, CNC Prototyping Service supports quicker decision-making and product refinement. This speeds up the entire development cycle, enabling businesses to launch products faster while staying ahead of competitors.

Conclusion

CNC Prototyping Service is an indispensable tool for custom product development. Its precision, flexibility, and material versatility ensure that manufacturers can create high-quality prototypes, streamline the design process, and bring innovative products to market with confidence and efficiency.