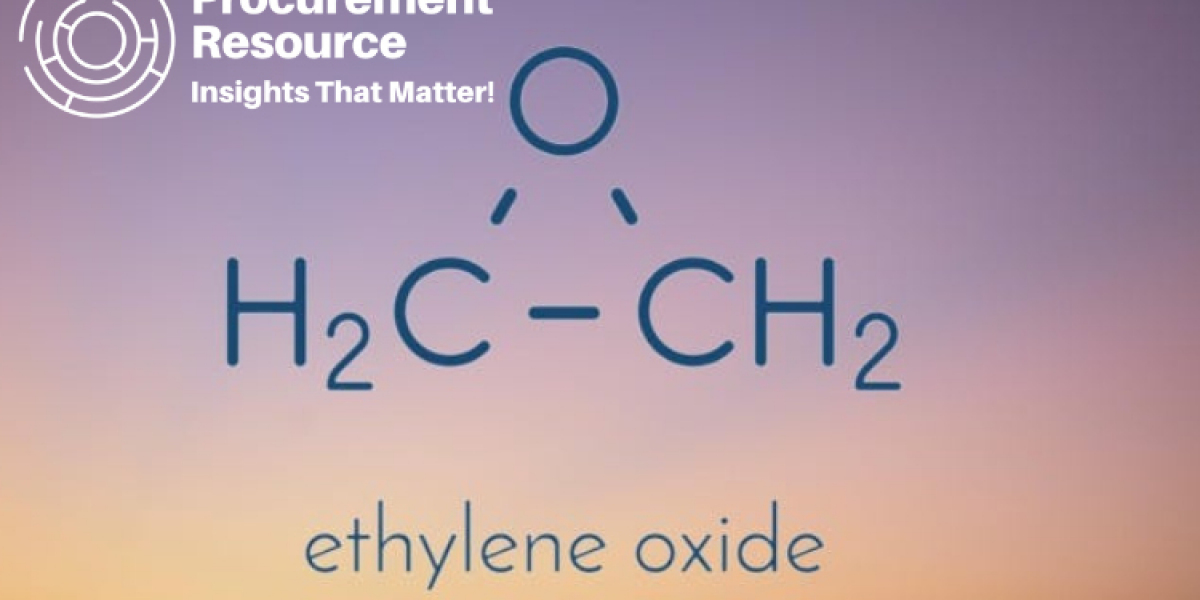

Ethylene oxide (EO) is a vital chemical used in a wide range of industries, including manufacturing, pharmaceuticals, and agriculture. It serves as a key intermediate in the production of products such as ethylene glycol, surfactants, and solvents, making it a cornerstone of global chemical production. For businesses operating in these industries, understanding the costs involved in ethylene oxide production is critical to maintaining competitiveness. At Procurement Resource, we provide detailed insights into the factors that drive ethylene oxide production costs, helping companies make well-informed decisions and optimise their operations.

Request a Free Sample for Ethylene Oxide Production Cost Reports

https://www.procurementresource.com/production-cost-report-store/ethylene-oxide/request-sample

Understanding the Key Drivers of Ethylene Oxide Production Costs

Ethylene oxide is primarily produced through the oxidation of ethylene, a process that requires significant energy, raw materials, and advanced technology. Below is a breakdown of the key cost factors that influence the production of ethylene oxide:

1. Raw Material Costs

The main feedstock for ethylene oxide production is ethylene, which is derived from either natural gas or crude oil. The cost of ethylene is often influenced by fluctuations in global oil and natural gas prices, as well as supply and demand dynamics in the energy market. Ethylene itself is usually produced through either steam cracking of hydrocarbons or other petrochemical processes, and the costs associated with these raw materials can represent a large portion of the overall production cost.

Read Full Report:

https://www.procurementresource.com/production-cost-report-store/ethylene-oxide

2. Energy Costs

Energy is one of the most significant cost drivers in ethylene oxide production. The process of oxidising ethylene to ethylene oxide requires high temperatures and substantial energy inputs. The energy-intensive nature of the process means that any increase in energy prices—whether in the form of natural gas, electricity, or steam—can lead to higher production costs. In particular, fluctuations in natural gas prices, which are closely linked to energy markets, have a direct impact on overall costs.

3. Labor and Operational Costs

The production of ethylene oxide involves complex chemical processes that require skilled labor to operate and monitor the equipment. Skilled engineers, technicians, and safety officers are required to maintain operations, ensure compliance with safety standards, and troubleshoot any production issues. Labor costs can vary significantly depending on the region and the level of automation in the plant, with more automated processes typically lowering labor costs. However, plants also need to invest in training, safety protocols, and compliance with environmental regulations.

4. Technological Advances and Equipment Maintenance

Ethylene oxide production plants must use advanced equipment, including reactors, compressors, and heat exchangers, to optimise the chemical reaction and increase efficiency. However, maintaining, upgrading, and replacing these machines involves significant capital investment. Furthermore, technological innovations such as catalysts and reaction optimization can help reduce costs over time by improving yield and energy efficiency, but these require an upfront investment in R&D and facility upgrades.

5. Environmental and Regulatory Costs

As environmental regulations become more stringent, especially with regards to emissions and waste management, companies producing ethylene oxide face increasing compliance costs. Ethylene oxide is a highly reactive compound, and managing its environmental impact is critical. Companies are investing in emission control technologies, carbon capture systems, and other sustainable practices to meet regulatory requirements and reduce their environmental footprint. These investments can add to production costs, but are essential for meeting compliance and maintaining a responsible environmental profile.

Ask an Analyst

https://www.procurementresource.com/production-cost-report-store/ethylene-oxide/ask-an-analyst

What Our Ethylene Oxide Production Cost Reports Offer

Procurement Resource’s Ethylene Oxide Production Cost Reports provide comprehensive data that helps businesses manage and optimise their production processes. Here’s what you can expect from our reports:

- Detailed Cost Breakdown: Our reports provide a comprehensive breakdown of all the costs involved in ethylene oxide production, including raw materials, energy, labor, equipment maintenance, and environmental compliance.

- Real-Time Market Data: The global ethylene oxide market is constantly evolving. Our reports provide up-to-date market trends and forecasts, helping you stay ahead of the curve and make informed decisions based on the latest data.

- Price Trends and Analysis: We track ethylene oxide pricing trends and market dynamics to provide you with actionable insights on pricing fluctuations, enabling you to anticipate price movements and adjust procurement strategies accordingly.

- Benchmarking and Comparison: Compare your production costs with industry benchmarks to identify areas where you may be able to reduce expenses or improve efficiency.

- Procurement Insights: Our expert analysts provide actionable procurement strategies to help you manage your ethylene oxide supply chain effectively and reduce overall production costs.

Stay Ahead with Procurement Resource

By partnering with Procurement Resource, you gain access to cutting-edge intelligence that helps you stay competitive in the ethylene oxide market. Our reports are designed to provide businesses with actionable insights to optimise production processes, improve cost management, and navigate the complexities of the global market.

We understand that each business has unique needs. That’s why we offer customizable reports to meet the specific requirements of your business, whether you’re looking to optimise costs, identify market opportunities, or understand regulatory challenges.

Request Your Free Sample Report Today

https://www.procurementresource.com/production-cost-report-store/ethylene-oxide/request-sample

Contact Us:

Company Name: Procurement Resource

Contact Person: Benking Sley

Email: sales@procurementresource.com

Toll-Free Numbers:

USA & Canada: +1 307 363 1045

UK: +44 7537171117

Asia-Pacific (APAC): +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA