According to TechSci Research report, “Hardbanding Services Market - Global Industry Size, Share, Trends, Opportunity, and Forecast 2018-2028”, The global Hardbanding Services market is witnessing remarkable growth as the oil and gas industry places increasing emphasis on extending the lifespan and reliability of drill strings in the face of complex and demanding drilling environments. Hardbanding services, which provide critical protection against wear and abrasion, are emerging as a pivotal solution to optimize drilling operations, reduce maintenance costs, and ensure safe and sustainable exploration and production activities.

Driven by the escalating complexity of drilling operations, the market is experiencing a surge in demand for effective measures that safeguard drill strings from the rigors of modern drilling. As exploration ventures into deeper waters, high-pressure/high-temperature reservoirs, and unconventional formations, drill strings face unprecedented forces of wear and tear. In response, the demand for robust solutions that can withstand these harsh conditions has soared. Hardbanding services are answering this call with coatings designed to provide exceptional wear resistance and protection, enabling drill strings to endure the challenging conditions encountered in contemporary drilling operations.

The industry's unyielding focus on maximizing the reliability and lifespan of drill strings has propelled the growth of the Hardbanding Services market. With oil and gas operators aiming to optimize the value of their drilling assets by extending operational lifecycles, hardbanding coatings have emerged as a proactive defense against premature wear and degradation of drill strings. By offering a resilient barrier against abrasive forces, these coatings minimize the frequency of maintenance interventions and associated downtime. This results in enhanced drilling efficiency, reduced operational disruptions, and ultimately greater returns on investment for drilling assets.

The demand for Hardbanding Services is further amplified by the global exploration of unconventional oil and gas resources. As the industry taps into unconventional reservoirs such as shale and tight formations, the need for specialized drilling techniques and equipment becomes evident. These distinctive drilling conditions necessitate tailored hardbanding solutions that address the specific wear patterns and operational challenges posed by unconventional formations. The role of hardbanding in optimizing drilling operations is highlighted as the industry invests in extracting resources from these unconventional plays.

In the face of stringent regulatory compliance and safety standards, the Hardbanding Services market is evolving to align with responsible environmental and occupational health practices. With environmental regulations and safety protocols shaping the oil and gas industry, operators are seeking hardbanding solutions that not only protect drill strings but also uphold stringent regulatory criteria. The demand for compliant and environmentally friendly hardbanding materials and techniques is on the rise as sustainability and safety take center stage in drilling operations.

Technological breakthroughs in hardfacing materials are driving transformation within the market. Manufacturers and researchers are pioneering new materials that offer superior wear resistance, adhesion, and durability. Advanced materials, including nanocomposite coatings and hybrid alloys, are being developed to meet the evolving demands of modern drilling operations. These materials provide enhanced protection against abrasion, corrosion, and thermal fatigue, addressing the industry's pursuit of optimal drill string protection, enhanced performance, and reduced operational costs.

As the global Hardbanding Services market expands, it serves as a pivotal pillar within the oil and gas industry, offering essential solutions that counter the wear-related challenges posed by intricate and diverse drilling environments. Factors such as the increasing complexity of drilling, the focus on drill string lifespan extension, the exploration of unconventional resources, regulatory compliance, and technological innovation are driving the growth and transformation of the market.

Browse over XX market data Figures spread through XX Pages and an in-depth TOC on the "Global Hardbanding Services Market."

https://www.techsciresearch.com/report/hardbanding-services-market/8189.html

The Global Hardbanding Services Market is segmented into type, application, component, location, and region. Based on type, the market is segmented into tungsten carbide, chromium carbide, titanium carbide and niobium boride. Based on application, the market is segmented into open hole, cased hole. Based on component, the market is segmented into drill pipe, drill collars, tool joints, others. Based on location, the market is segmented into onshore, offshore. Based on region, the market is further bifurcated into North America, Asia-Pacific, Europe, South America, Middle East & Africa.

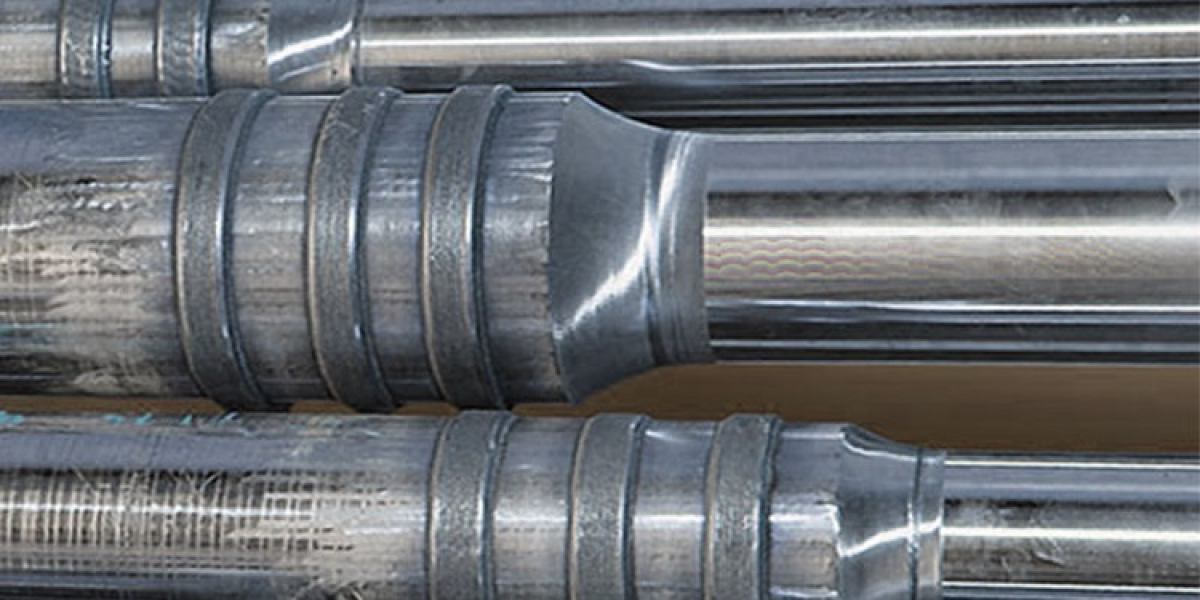

Based on component, drill pipe dominates in the global Hardbanding Services market in 2022. The drill pipe segment holds a pivotal position in the market due to its central role in the drilling process. Drill pipes serve as the conduit through which drilling fluids are circulated and torque is transmitted to the drill bit. However, this crucial component is subject to substantial wear and abrasion during drilling operations, especially when navigating through abrasive formations, high-pressure conditions, and corrosive environments. To combat these challenges and prolong the operational life of drill pipes, hardbanding services are extensively utilized.

The dominance of the drill pipe segment can be attributed to several factors. Firstly, drill pipes are subject to constant movement, rotation, and exposure to abrasive materials, making them highly susceptible to wear-related issues. Hardbanding coatings, which offer wear resistance and protection against abrasion and erosion, provide a critical solution to mitigate these challenges. As a result, operators seek hardbanding services to preserve the integrity and efficiency of drill pipes, enhancing their longevity and reducing maintenance downtime.

Key market players in the global Hardbanding Services market are: -

- Hardfacing Technologies, LLC

- Welding Alloys & Services, Inc.

- Therm-A-Line Industries, Inc.

- Midwest Hardfacing, Inc.

- ITR International

- Hard Steel Lines, LLC

- Allied Grinding & Machine, Inc.

- A&A Hardfacing, Inc.

- Welding Specialists, Inc.

- Metal Improvement Services, Inc.

Download Free Sample Report

https://www.techsciresearch.com/sample-report.aspx?cid=8189

Customers can also request for 10% free customization on this report.

“The Global Hardbanding Services market is a thriving sector within the oil and gas industry, driven by the need to protect drill strings from wear and abrasion in increasingly challenging drilling environments. As drilling operations venture into deeper waters, high-pressure/high-temperature reservoirs, and unconventional formations, the demand for robust solutions to extend drill string lifespan and enhance operational efficiency has surged.

Hardbanding services play a vital role by applying wear-resistant coatings that safeguard drill strings from abrasive forces, erosion, and corrosion. The market's growth is fueled by the industry's focus on reliability, sustainability, and compliance with stringent environmental and safety regulations.

Moreover, advancements in hardfacing materials and techniques are shaping the market, enabling the development of innovative coatings that address specific wear mechanisms. In a landscape marked by evolving drilling conditions, regulatory pressures, and technological progress, the Global Hardbanding Services market continues to evolve to meet the demands of the dynamic oil and gas exploration sector.” said Mr. Karan Chechi, Research Director with TechSci Research, a research-based global management consulting firm.

“Hardbanding Services Market – Global Industry Size, Share, Trends, Opportunity, and Forecast. Segmented By Type (Tungsten Carbide, Chromium Carbide, Titanium Carbide and Niobium Boride), By Application (Open Hole, Cased Hole), By Component (Drill Pipe, Drill Collars, Tool Joints, Others), By Location (Onshore, Offshore), By Region, By Company and By Geography, Forecast & Opportunities, 2018-2028,” has evaluated the future growth potential of Global Hardbanding Services Market and provides statistics & information on market size, structure, and future market growth. The report intends to provide cutting-edge market intelligence and help decision makers take sound investment decisions. Besides the report also identifies and analyzes the emerging trends along with essential drivers, challenges, and opportunities in Global Hardbanding Services Market.

Contact

Techsci Research LLC

420 Lexington Avenue, Suite 300,

New York, United States- 10170

Tel: +13322586602

Email: sales@techsciresearch.com

Website: www.techsciresearch.com