Introduction to HIL Testing

Ensuring software and hardware components function seamlessly in the fast-paced world of embedded systems is crucial. Hardware-in-the-loop (HIL) Testing has become a go-to solution for developers seeking reliable and efficient validation methods. By simulating real-world scenarios, HIL Testing provides a risk-free environment to test embedded systems thoroughly. For companies like Servotech, embracing HIL Testing is a significant step towards achieving high-quality and robust solutions.

What is HIL Testing?

HIL Testing stands for Hardware-in-the-Loop Testing. This technique allows developers to test software and hardware interactions using real-time simulation. The primary goal is to validate the control systems without the need for a complete physical prototype. By integrating simulated inputs with the actual control hardware, engineers can identify issues early in the development process.

Why HIL Testing is Important

HIL Testing bridges the gap between virtual simulations and real-world testing. It helps reduce the risks associated with product launch by providing a comprehensive testing environment. For industries like automotive and aerospace, where safety and reliability are paramount, HIL Testing ensures that the control systems work as expected under various conditions.

Key Benefits of HIL Testing

- Early Issue Detection: By simulating real-world scenarios, HIL Testing enables engineers to detect software and hardware issues early in the development phase, reducing costly fixes later.

- Cost-Efficient Validation: Instead of building multiple physical prototypes, HIL Testing uses simulated environments, cutting down on time and expenses.

- Enhanced Product Reliability: It provides thorough testing of control systems, ensuring the final product meets quality and performance standards.

HIL Testing vs. Traditional Testing Methods

Traditional testing methods often involve direct testing on physical prototypes, which can be time-consuming and expensive. In contrast, HIL Testing uses a simulated environment to test the software and hardware components in real-time. This not only accelerates the development process but also enhances the accuracy of the tests.

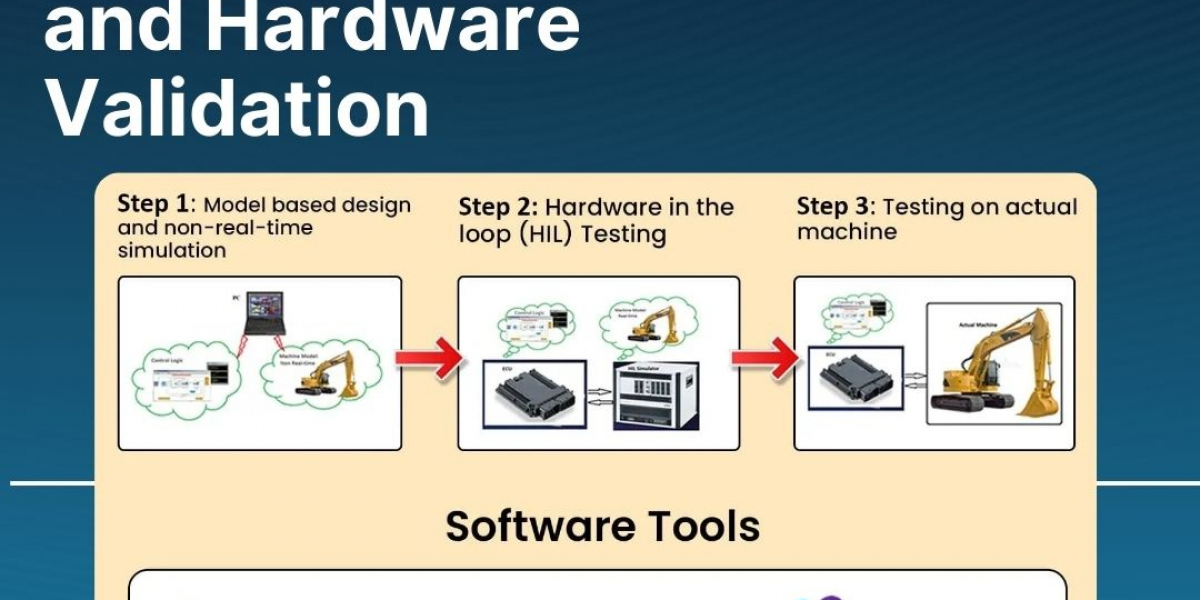

How HIL Testing Works

The process of HIL Testing involves connecting the control system to a simulation model that mimics real-world conditions. The simulation model provides inputs to the control system, and the system's responses are analyzed. This setup allows developers to test various scenarios without the need for an actual physical setup.

Applications of HIL Testing

HIL Testing is widely used across various industries, including:

- Automotive: Testing of electronic control units (ECUs) to ensure vehicle safety and performance.

- Aerospace: Validation of flight control systems under simulated conditions.

- Industrial Automation: Ensuring machinery control systems respond accurately to simulated inputs.

Challenges in HIL Testing

Despite its numerous benefits, implementing HIL Testing can present some challenges:

- Complex Setup: The integration of simulation models with control systems requires specialized skills and knowledge.

- High Initial Cost: The setup of HIL Testing systems can be costly, although it pays off in the long run through reduced development time and improved product reliability.

Best Practices for HIL Testing

To maximize the benefits of HIL Testing, it is essential to follow some best practices:

- Comprehensive Simulation Models: Use detailed and accurate simulation models to mimic real-world scenarios effectively.

- Regular Updates: Keep the testing environment updated with the latest software versions and configurations.

- Continuous Monitoring: Regularly monitor the test results to identify and address issues promptly.

Servotech's Approach to HIL Testing

At Servotech, we leverage advanced HIL Testing techniques to ensure the highest quality in our embedded software solutions. By simulating real-world conditions, we help clients achieve robust and reliable products, reducing the time to market and ensuring compliance with industry standards.

Conclusion

HIL Testing is a powerful tool for efficient software and hardware validation, enabling early issue detection, cost savings, and enhanced product reliability. For companies like Servotech, adopting HIL Testing practices ensures a robust development process, delivering high-quality products to meet the demands of industries like automotive, aerospace, and industrial automation. Embracing this testing method can be a game-changer for businesses looking to stay ahead in the competitive market.

For more information on how Servotech can assist with your HIL Testing needs, visit our HIL Software Testing page.