The global polyisobutylene market was valued at USD 1.87 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of 4.0% from 2021 to 2028. This market growth is largely driven by the diverse applications of polyisobutylene, which include its use in adhesives and sealants, rubber components in the automotive sector, as well as in fuel and lubricant additives. The increasing popularity of tubeless tires in the automotive industry—due to their ease of replacement and lower maintenance requirements—has further contributed to this growth. Polyisobutylene serves as an effective barrier to oxygen, making it an ideal material for the inner liners of tubeless tires. Notably, polyisobutylene (PIB) is characterized by low moisture and gas permeability, along with excellent electrical insulation properties.

The COVID-19 pandemic led to a significant shift toward remote work, resulting in increased voice traffic, residential broadband usage, and mobile data consumption. In response, the telecommunications industry adapted well, leveraging optical fibers to provide reliable internet connections, thereby enhancing user experience. This expansion in the telecom sector is anticipated to boost the demand for polyisobutylene as a material for cable insulation in electrical and electronics applications.

Gather more insights about the market drivers, restrains and growth of the Polyisobutylene Market

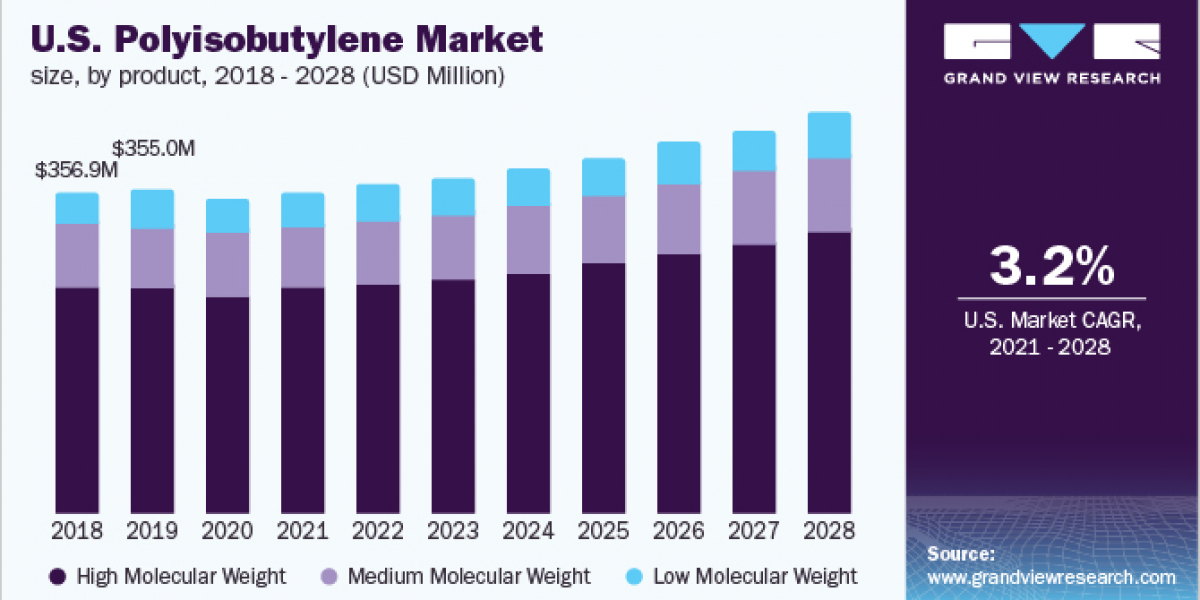

Product Segmentation Insights

In 2020, high molecular weight polyisobutylene dominated the market, accounting for over 65.0% of total revenue. Polyisobutylene is categorized into high, medium, and low molecular weight based on its molecular weight range. High molecular weight polyisobutylene is a transparent, rubber-like solid with ultra-high viscosity. Its elevated molecular weight enables it to maintain exceptional elasticity and resilience. These desirable properties allow it to be utilized in a variety of applications, such as stretch films, lubricants, and adhesives across industrial, transportation, and food sectors.

Medium molecular weight polyisobutylene is particularly valued for its tackiness and plasticizing properties, making it effective in adhesives. When blended with low-density polyethylene, it enhances the film's tear resistance, flexibility at low temperatures, and clinging ability. This type of polyisobutylene is also commonly employed in food and beverage packaging, thanks to its hydrophobic stability, antibacterial performance, adhesive qualities, and compliance with food safety standards.

Order a free sample PDF of the Market Intelligence Study, published by Grand View Research.