Syndicated Analytics’ latest report, titled “Epoxy Plasticizer Manufacturing Plant Project Report 2024: Industry Analysis (Market Performance, Segments, Price Analysis, Outlook), Detailed Process Flow (Product Overview, Unit Operations, Raw Materials, Quality Assurance), Requirements and Cost (Machinery, Raw Materials, Packaging, Transportation, Utility, Human Resource), Project Economics (Capital Investments, Operating Costs, Profit Projections, Financial Analysis, Revenue), and Investment Opportunities,” provides comprehensive insights for establishing an epoxy plasticizer manufacturing plant. The report covers industry performance, key success factors, risk factors, manufacturing requirements, project costs and economics, expected ROI, and profit margins. It combines desk research and qualitative primary research, making it an essential resource for entrepreneurs, investors, researchers, consultants, and business strategists planning to enter the epoxy plasticizer industry.

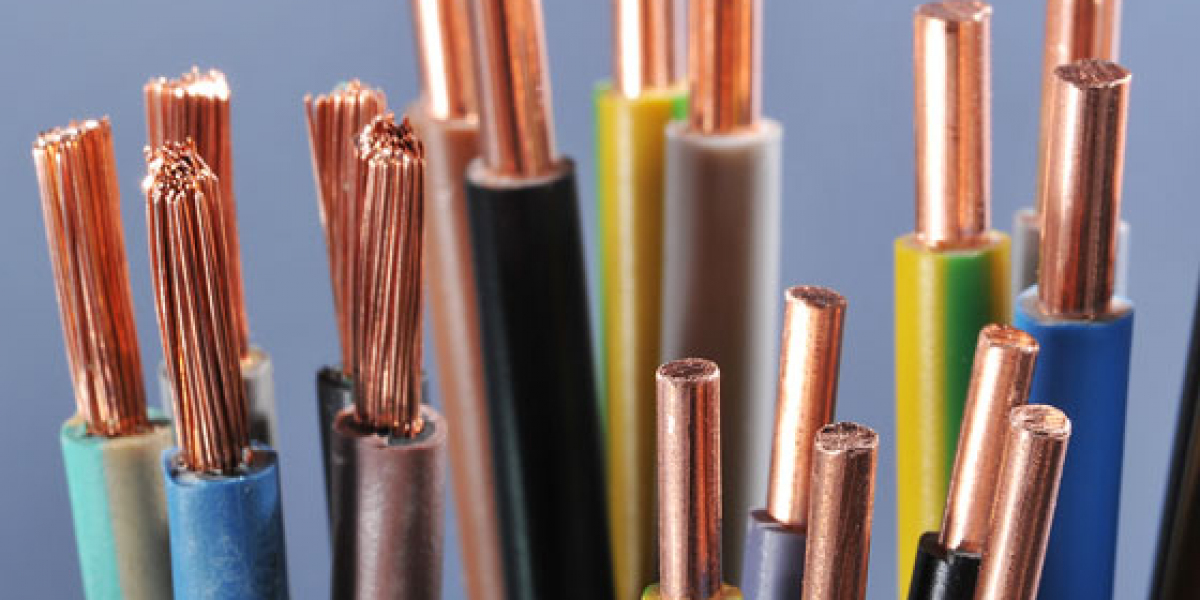

Epoxy plasticizers are specialized chemical additives used in the production of many plastic and polymer products to enhance their flexibility, durability, and performance. These plasticizers are derived from epoxy compounds and are typically added to materials like polyvinyl chloride (PVC) to reduce stiffness, making the resulting material more pliable and easier to handle.

Epoxy plasticizers are highly valued in industries where the balance between flexibility as well as strength is crucial, such as automotive, construction, and packaging. They offer a wide range of advantages, including enhanced thermal stability, low volatility, and excellent compatibility with other polymer materials, making them an essential component in various industrial applications.

Request For a Sample Report: bit.ly/432hzon

The primary driver for the epoxy plasticizer market is the growing demand for flexible and durable plastic products in various industries. In the construction sector, for example, the need for flexible PVC in wiring, pipes, and flooring has led to an escalated demand for epoxy plasticizers, as they ensure the material remains durable yet pliable under different conditions.

Similarly, the automotive industry requires materials that can withstand high temperatures and mechanical stress while maintaining flexibility, making epoxy plasticizers an essential additive in the production of automotive components. The packaging industry also benefits from the use of these plasticizers, as they help produce materials that are both flexible and resistant to external factors, ensuring the integrity of packaging for food, pharmaceuticals, and other sensitive products.

Moreover, environmental concerns and regulations surrounding the use of phthalate-based plasticizers have driven manufacturers to seek safer alternatives, with epoxy plasticizers emerging as a favorable option due to their lower toxicity and reduced environmental impact.

The future of the epoxy plasticizer market looks promising, with innovations in material science leading to the development of even more efficient and environmentally friendly plasticizer solutions. As industries continue to prioritize sustainability, the demand for bio-based and low-toxicity plasticizers will likely increase, further boosting the market. Additionally, advancements in polymer technology and the increasing focus on circular economies are expected to open new avenues for epoxy plasticizers in the years to come.

Which aspects are covered in our report on setting up an epoxy plasticizer manufacturing plant?

Market Overview:

- Market Performance

- Regional Insights

- Key Market Segmentation

- Price Trend Analysis

- COVID-19 Impact

- Market Outlook

- Market Key Players Analysis

Manufacturing Operations:

- Product Description and Insights

- Detailed Process Flow

- Identification of Unit Operations Involved

- Mass Balance Analysis and Raw Material Requirements

- Quality Control

Project Requirements, Details, and Costs:

- Site Development, Location, and Land Requirements

- Plant Layout

- Machinery Requirements and Associated Costs

- Raw Material Requirements and Associated Costs

- Packaging Requirements and Associated Costs

- Transportation Requirements and Associated Costs

- Utility Requirements and Associated Costs

- Manpower Requirements and Associated Costs

Project Financial Analysis:

- Capital Investments Analysis

- Operating Costs Analysis

- Expenditure Projections Analysis

- Revenue Projections Analysis

- Taxation and Depreciation Analysis

- Profit Projections Analysis

- Comprehensive Financial Analysis

Ask An Analyst: https://www.syndicatedanalytics.com/request?type=report&id=1872&flag=C

Need Customized Project Report?

You can share any particular business requirements that you have, and we will adjust the scope of the report to your needs. The following are some typical customizations that our clients ask for:

- The report may be customized based on the region/country in which you intend to locate your business.

- The production capacity of the facility can be customized in accordance with your needs.

- Suppliers of machinery and prices can be tailored to your requirements.

- Depending on your needs, we may also modify the current scope.

Key Questions Addressed in the Report on Epoxy plasticizer Manufacturing Project:

- How has the performance of the epoxy plasticizers market been thus far, and what can be expected in the upcoming years?

- What is the market segmentation of the global epoxy plasticizer market?

- What is the regional distribution of the global epoxy plasticizer market?

- What are the price trends of various feedstocks in the epoxy plasticizers industry?

- What is the structure of the epoxy plasticizers industry, and who are the major players?

- What are the different unit operations involved in the manufacturing of epoxy plasticizers?

- What is the total land area required for the establishment of an epoxy plasticizer manufacturing plant?

- What is the layout of an epoxy plasticizers manufacturing plant?

- What are the machinery requirements for establishing an epoxy plasticizer manufacturing plant?

- What are the raw material requirements for setting up an epoxy plasticizer manufacturing plant?

- What are the packaging requirements for establishing an epoxy plasticizer manufacturing plant?

- What are the transportation requirements for establishing an epoxy plasticizer manufacturing plant?

- What are the utility requirements for establishing an epoxy plasticizers manufacturing plant?

- What are the human resource requirements for establishing an epoxy plasticizer manufacturing plant?

- What are the infrastructure costs associated with establishing an epoxy plasticizer manufacturing plant?

- What are the capital costs involved in setting up an epoxy plasticizers manufacturing plant?

- What are the operating costs associated with establishing an epoxy plasticizer manufacturing plant?

- What should be the pricing mechanism for the final product?

- What will be the income and expenditures for an epoxy plasticizer manufacturing plant?

- What is the timeframe required to achieve the break-even point?

- What are the profit projections for establishing an epoxy plasticizer manufacturing plant?

- What are the key factors for success and risks in the epoxy plasticizer industry?

- What are the essential regulatory procedures and requirements for establishing an epoxy plasticizer manufacturing plant?

- What are the necessary certifications required for establishing an epoxy plasticizer manufacturing plant?

Browse Other Reports:

Phosphorus Pentoxide Manufacturing Plant Project Report

Phosphorus Oxychloride Manufacturing Plant Project Report

Phenylpropanolamine Manufacturing Plant Project Report

Phenyl Isothiocyanate Manufacturing Plant Project Report

Phenyl Acetaldehyde Manufacturing Plant Project Report

Our Unique Methodology at Syndicated Analytics:

- We offer a suite of services that provide comprehensive coverage of global markets, including a market snapshot and regional coverage. We understand the importance of customization and offer tailored reports to meet your individual scope or regional requirements.

- Our research team utilizes exhaustive primary research methodologies, including collaboration with industry players, to gather accurate and reliable information. Additionally, we employ multiple waves of secondary desk-based research to provide a deep understanding of the market. Our analysts cross-validate the findings to ensure the data’s accuracy and validity.

- To provide impactful insights for our clients, we have a vast collection of research databases and data repositories. This allows us to draw from a wealth of information to create the most relevant and up-to-date insights. We are committed to providing high-quality research services to drive our clients’ success.

About Us:

Syndicated Analytics, a subsidiary of IMARC Group, offers consulting services and provides comprehensive market intelligence in the form of research reports, production cost reports, and feasibility studies. Our team, consisting of experienced researchers and analysts from diverse industries, is deeply committed to the quality of the information and insights delivered to the clients, which range from small and medium enterprises to Fortune 1000 companies. These firms are able to achieve this by studying the qualitative and quantitative aspects of the market as well as staying up to date with the current and evolving trends of the industry.

Contact Info:

Katherine Shields

Senior Sales & Marketing Manager

134 N 4th St. Brooklyn,

NY 11249, USA

Phone No: +1-213-316-7435

Website: https://www.syndicatedanalytics.com/

Email Address: sales@syndicatedanalytics.com