Semiconductor bonding is a fundamental process in the assembly of electronic devices, involving the joining of semiconductor materials to form integrated circuits (ICs) and other electronic components. This process is crucial for ensuring the functionality, reliability, and performance of semiconductor devices. Semiconductor bonding techniques encompass various methods, including wire bonding, flip-chip bonding, and die attach, each tailored to specific applications and requirements.

The semiconductor industry has witnessed rapid advancements in bonding technologies, driven by the increasing demand for smaller, faster, and more efficient electronic devices. As devices become more complex, the need for reliable and high-performance bonding methods has never been more critical. Innovations in materials, processes, and equipment are enabling manufacturers to meet the challenges of modern semiconductor packaging.

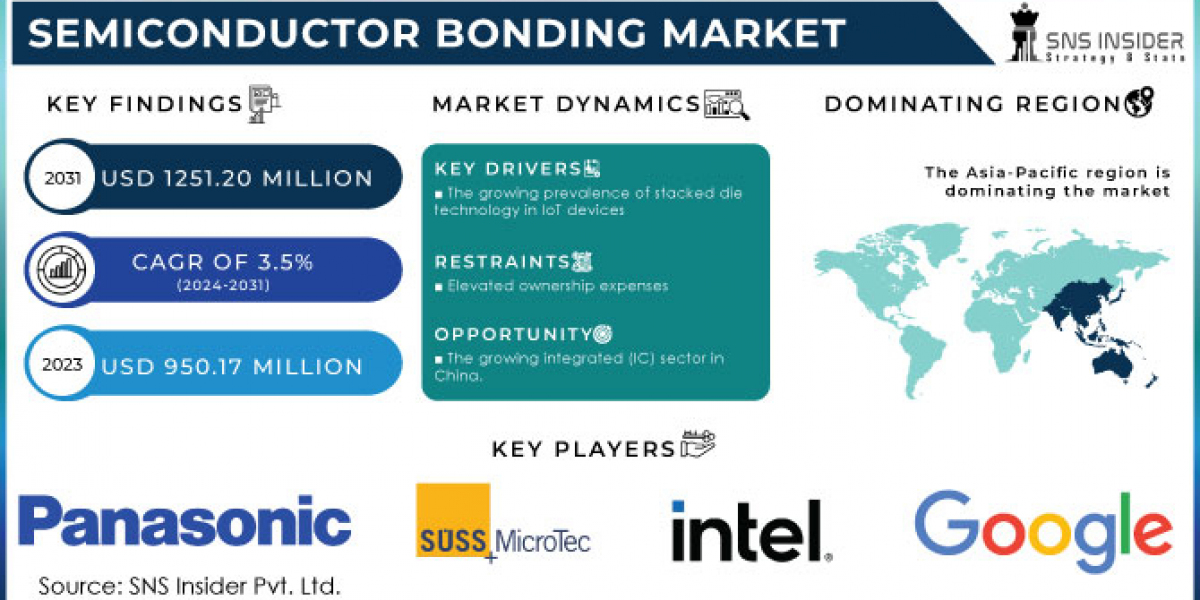

The Semiconductor Bonding Market Size was valued at USD 950.17 Million in 2023 and is expected to reach USD 1251.20 Million by 2031 and grow at a CAGR of 3.5% over the forecast period 2024-2031.

Future Scope

The future of semiconductor bonding is promising, with significant growth expected as the demand for advanced electronic devices continues to rise. As industries explore new applications for semiconductors in fields such as artificial intelligence (AI), the Internet of Things (IoT), and automotive electronics, the need for innovative bonding solutions will expand.

Moreover, the ongoing development of advanced materials, such as novel adhesives and bonding techniques, will enhance the performance and reliability of semiconductor devices. As manufacturers strive to improve the efficiency and effectiveness of bonding processes, advancements in automation and precision will play a crucial role in shaping the future of semiconductor assembly.

Trends

Several key trends are influencing the semiconductor bonding market. One notable trend is the increasing adoption of flip-chip bonding technology, which offers improved electrical performance and thermal conductivity compared to traditional wire bonding. This method is gaining traction in high-performance applications, including high-frequency and high-power devices.

Another trend is the growing emphasis on sustainability in semiconductor manufacturing. As industries seek to minimize waste and reduce environmental impact, the adoption of eco-friendly bonding materials and processes will become increasingly important. Manufacturers are exploring alternatives to traditional materials, aligning with sustainability goals.

Application

Semiconductor bonding finds applications across various sectors, including consumer electronics, automotive, telecommunications, and industrial automation. In consumer electronics, bonding processes are used to assemble components in smartphones, tablets, and other devices, ensuring their functionality and reliability.

In the automotive sector, semiconductor bonding is critical for the production of electronic control units (ECUs) and sensors. The increasing complexity of automotive electronics necessitates robust bonding solutions to ensure performance and safety in vehicles.

Additionally, semiconductor bonding is vital in telecommunications, where it supports the assembly of high-frequency components used in network infrastructure and communication devices. The reliability and performance of these components are essential for maintaining high-quality communication services.

Key Points

- Fundamental process in assembling electronic devices and integrated circuits.

- Rapid advancements driven by demand for smaller and more efficient devices.

- Future growth supported by applications in AI, IoT, and automotive electronics.

- Trends include increased adoption of flip-chip bonding and sustainable materials.

- Applied across consumer electronics, automotive, telecommunications, and industrial sectors.

Read More Details: https://www.snsinsider.com/reports/semiconductor-bonding-market-2203

Contact Us:

Akash Anand — Head of Business Development & Strategy

Email: info@snsinsider.com

Phone: +1–415–230–0044 (US) | +91–7798602273 (IND)