Heat exchangers are critical components in industries where temperature regulation is essential. Plate and tube heat exchangers, in particular, have gained widespread use due to their efficient heat transfer capabilities. Whether in HVAC systems, power plants, chemical processing, or refrigeration, these heat exchangers are vital for maintaining optimal temperature conditions in a variety of systems. The plate and tube heat exchanger market is projected to reach USD 884 million by 2028, at a CAGR of 6.5%. The report presents and showcases a dynamic vision of the global scenario in terms of market size, share, growth, demand, plate and tube heat exchanger market trends, market statistics, and competitive situation.

What is a Plate and Tube Heat Exchanger?

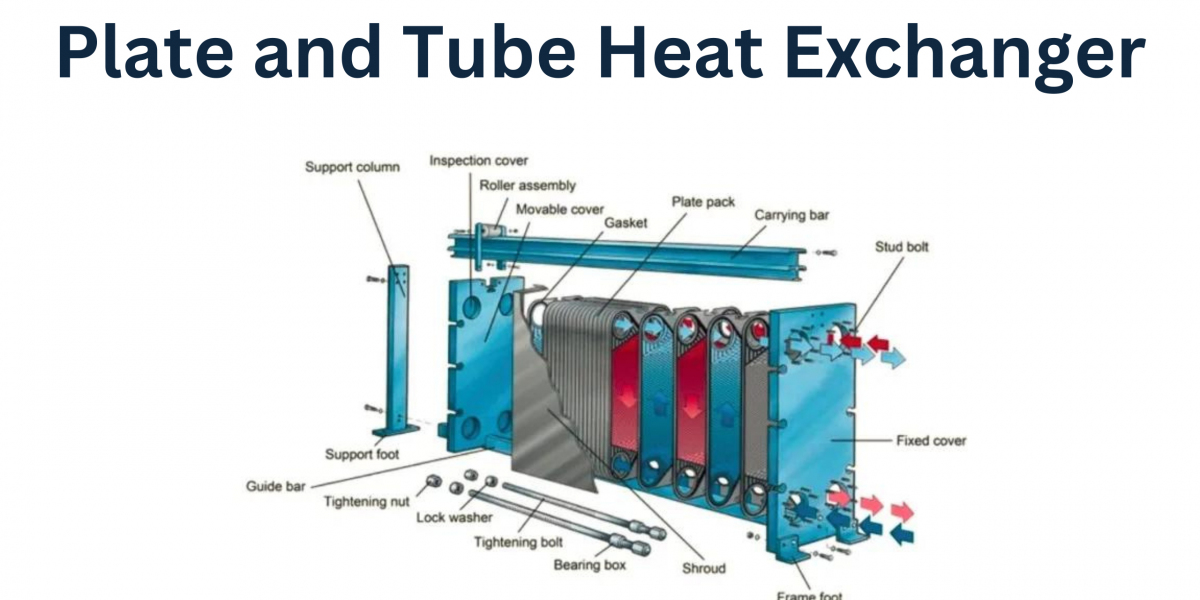

Plate and tube heat exchangers are designed to transfer heat between two fluids without mixing them. These devices are essential for energy efficiency, allowing industries to recycle heat or cool down equipment. There are two major types of heat exchangers:

▶ Plate Heat Exchanger: This type consists of thin plates stacked together. The fluid flows over the plates, and heat is transferred through the surface of the plates. Due to their compact design and high efficiency, plate heat exchangers are commonly used in HVAC systems, refrigeration, and the food and beverage industry.

▶ Tube Heat Exchanger: Tube heat exchangers consist of tubes that allow fluids to flow inside and outside the tubes. The heat is transferred between the fluids through the tube walls. These heat exchangers are often found in heavy-duty applications like oil refineries, power plants, and chemical processing plants due to their ability to handle high temperatures and pressures.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=209217587

Growing Demand for Plate and Tube Heat Exchangers

The demand for plate and tube heat exchangers is rising steadily, driven by their widespread application in multiple industries. Several factors are contributing to this growing demand:

✔️ Increasing Energy Efficiency Requirements

With growing environmental concerns and rising energy costs, industries are focusing on energy-efficient solutions. Plate and tube heat exchangers help recycle energy by transferring heat from one fluid to another, thus minimizing energy waste. This is especially crucial in industries like power generation, HVAC, and chemical processing.

✔️ Expanding Industrialization and Urbanization

As industrialization continues to grow in emerging economies, the demand for efficient heat management solutions is rising. In sectors such as petrochemicals, food processing, and pharmaceuticals, the need for heat exchangers that offer reliable, high-performance thermal management is expanding rapidly.

✔️ Growth in HVAC and Refrigeration Industries

The HVAC (heating, ventilation, and air conditioning) and refrigeration sectors are major users of plate and tube heat exchangers. With increased construction activity and rising demand for efficient building systems, HVAC systems equipped with efficient heat exchangers are in high demand. Similarly, the refrigeration industry, crucial for food and pharmaceutical storage, is also driving the demand for these devices.

✔️ Power Generation Industry's Demand for High-Performance Heat Exchangers

The power generation industry requires high-performance heat exchangers for thermal regulation in processes like steam turbines, boilers, and cooling towers. The ability of plate and tube heat exchangers to withstand high temperatures and pressures makes them an ideal choice in this sector. As the global demand for energy continues to rise, so does the demand for heat exchangers in power plants.

✔️ Growth of Renewable Energy Sectors

Renewable energy systems, particularly solar and geothermal plants, utilize heat exchangers to transfer heat effectively. The shift towards green energy is also contributing to the demand for advanced plate and tube heat exchangers that can operate efficiently in these emerging sectors.

Get Sample Copy of this Report: https://www.marketsandmarkets.com/requestsampleNew.asp?id=209217587

Top Plate and Tube Heat Exchanger Companies

Several key companies are leading the global plate and tube heat exchanger market. These manufacturers have built a reputation for producing high-quality, durable heat exchangers that meet the specific needs of various industries.

☑️ Alfa Laval AB

Alfa Laval, based in Sweden, is a global leader in heat transfer technology. The company specializes in producing both plate and tube heat exchangers that are used in industries ranging from food and beverage to energy and marine. Alfa Laval's innovative solutions have made it one of the top manufacturers in the world.

☑️ Kelvion Holding GmbH

Kelvion is a German-based company known for its extensive range of heat exchangers, including both plate and tube models. Kelvion serves industries such as power generation, oil and gas, chemical processing, and HVAC. The company is renowned for its custom-engineered heat exchangers that cater to specific industrial requirements.

☑️ Danfoss A/S

Danfoss, headquartered in Denmark, is a leading manufacturer of energy-efficient heat transfer solutions. The company offers high-performance plate heat exchangers for HVAC, refrigeration, and industrial applications. Danfoss's focus on energy-efficient technologies positions it as a key player in the market.

☑️ SPX Flow, Inc.

SPX Flow, an American-based company, provides a wide range of industrial heat exchangers, including plate and tube designs. The company's heat exchangers are widely used in the food, beverage, and pharmaceutical industries. SPX Flow is known for producing heat exchangers that deliver high thermal efficiency and durability.

☑️ Xylem Inc.

Xylem, based in the United States, is a global leader in water and fluid technologies, including heat exchanger systems. The company's heat exchangers are used in a variety of industries, including wastewater treatment, HVAC, and industrial manufacturing. Xylem’s focus on sustainable solutions is driving innovation in heat transfer technologies.

☑️ SWEP International AB

SWEP, a part of Dover Corporation, is a Swedish company that focuses on brazed plate heat exchangers. These highly compact and efficient heat exchangers are used in HVAC, refrigeration, and process industries. SWEP's energy-saving products are popular in sectors where space constraints and efficiency are crucial.

Inquire Before Buying: https://www.marketsandmarkets.com/Enquiry_Before_BuyingNew.asp?id=209217587

Future Outlook for Plate and Tube Heat Exchangers

As industries continue to focus on improving energy efficiency and sustainability, the demand for plate and tube heat exchangers is expected to rise. Technological advancements, such as the development of more durable materials and advanced thermal transfer technologies, will further drive growth in this market.

In addition, the global shift towards renewable energy sources will create new opportunities for heat exchanger manufacturers. With the increasing use of solar, wind, and geothermal energy, demand for efficient heat exchangers that can manage the thermal requirements of these systems will grow.

Conclusion

Plate and tube heat exchangers play a vital role in industries where efficient heat transfer is required. The rising demand for energy-efficient systems, industrialization, and the growing renewable energy sector are all contributing to the expanding market for these heat exchangers. Leading companies such as Alfa Laval, Kelvion, Danfoss, and others are setting the standard for innovation and quality in this competitive market.

As the need for thermal management solutions continues to increase across industries, the future for plate and tube heat exchangers looks bright. With their ability to efficiently transfer heat, reduce energy consumption, and contribute to sustainable practices, these devices will remain essential to industries worldwide.