In the world of industrial machinery, bearings are integral components that influence the performance and longevity of equipment. As technology progresses, the demand for high-performance bearings that can handle advanced operational requirements grows. AUBEARING is at the forefront of this industry transformation, setting new standards with its cutting-edge bearing solutions. This article delves into how AUBEARING is revolutionizing the bearing market and what makes its products stand out.

Pioneering Bearing Technology with AUBEARING

AUBEARING has become synonymous with innovation in bearing technology. The company’s relentless pursuit of excellence is evident in its approach to product development, material science, and manufacturing processes. Let’s explore how AUBEARING’s groundbreaking methods are shaping the future of bearings:

1. Advanced Material Utilization

At the heart of AUBEARING’s innovation is its use of advanced materials. By incorporating high-performance materials such as hybrid ceramics, advanced steel alloys, and engineered polymers, AUBEARING produces bearings that excel in durability and efficiency. These materials are chosen for their superior resistance to wear, corrosion, and extreme temperatures, ensuring that AUBEARING’s bearings perform optimally in diverse environments.

2. Precision Engineering for Superior Performance

Precision is critical in bearing design, and AUBEARING excels in this area with its state-of-the-art engineering techniques. The company employs high-precision machining, advanced surface treatments, and meticulous assembly methods to produce bearings with exacting tolerances. This focus on precision minimizes friction and maximizes efficiency, leading to smoother operation and longer service life for machinery.

3. Custom Solutions for Varied Applications

Understanding that different industries have unique requirements, AUBEARING offers a range of custom bearing solutions. Whether it’s for high-speed applications, heavy-duty machinery, or environments with extreme temperatures, AUBEARING’s design team works closely with clients to develop bearings tailored to specific needs. This custom approach ensures that each bearing delivers optimal performance in its intended application.

4. Rigorous Testing and Quality Control

Quality is a cornerstone of AUBEARING’s product development process. Each bearing undergoes a series of rigorous tests to ensure it meets the company’s stringent quality standards. These tests include load simulations, endurance testing, and environmental resistance assessments. By thoroughly evaluating each product, AUBEARING guarantees that its bearings provide reliable performance under a variety of conditions.

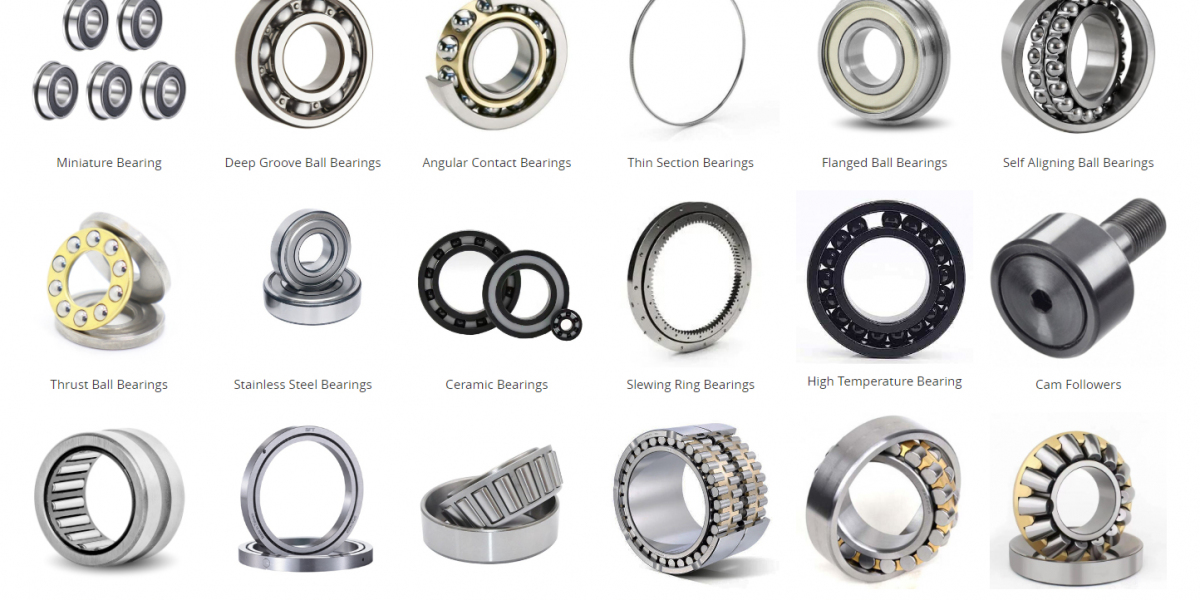

AUBEARING’s Diverse Product Portfolio

AUBEARING offers an extensive range of bearing solutions designed to meet the demands of various industries. Here’s an overview of their key product categories:

High-Speed Bearings: Engineered for applications requiring high rotational speeds, such as in turbines and electric motors. These bearings are optimized for low friction and stability at high velocities.

Heavy-Duty Bearings: Built to withstand high loads and harsh operating conditions, making them ideal for use in industrial machinery and construction equipment.

Temperature-Resistant Bearings: Designed to perform reliably in extreme temperature environments, such as in ovens and engines, these bearings are constructed from materials that maintain their properties under high heat.

Corrosion-Resistant Bearings: Featuring materials that resist corrosion, these bearings are suitable for use in marine, chemical, and food processing environments where exposure to harsh substances is common.

Custom Bearings: For specialized applications, AUBEARING provides custom-engineered bearings tailored to specific operational needs, including variations in size, material, and performance features.

Why Choose AUBEARING?

AUBEARING’s reputation as a leader in the bearing industry is built on several key factors:

1. Cutting-Edge Technology

AUBEARING invests heavily in research and development to stay ahead of technological advancements. The company’s commitment to innovation ensures that its bearings incorporate the latest technologies and materials, providing customers with state-of-the-art solutions.

2. Exceptional Customer Support

Customer satisfaction is a priority for AUBEARING. The company offers dedicated support to assist clients with their specific needs, from product selection to after-sales service. This personalized approach helps clients find the right solutions and ensures ongoing support.

3. Global Presence with Local Expertise

AUBEARING’s global distribution network allows it to serve clients worldwide, while its local expertise ensures timely delivery and support. The company’s efficient logistics and responsive service enhance the overall customer experience.

4. Environmental Responsibility

AUBEARING is committed to sustainability and eco-friendly practices. The company incorporates energy-efficient manufacturing processes and uses environmentally responsible materials, reflecting its dedication to reducing the ecological impact of its operations.

Experience the Future of Bearings with AUBEARING

As a trusted ceramic balls wholesaler, we provide high-quality ceramic balls that meet the rigorous demands of various industries. AUBEARING is leading the way in bearing technology with its innovative solutions and dedication to quality. Whether you need bearings for high-speed, heavy-duty, or specialized applications, AUBEARING provides the expertise and technology to meet your requirements.

For more information on AUBEARING’s products and how they can enhance your operations, contact them today:

- Email: info@aubearing.com

- Phone: +86 15006356216

- Address: No. 118, Industrial Park, Yandian Town, Linqing City, Shandong Province, China

AUBEARING—where innovation meets reliability in bearing technology.