In today's fast-paced food industry, efficiency and productivity are essential for staying competitive. If your business is involved in the production of momos, dumplings, or any other dough-based products, investing in a Momo Sheeter Machine can be a game changer. At Chefs Shop, we provide state-of-the-art momo sheeter machines designed to streamline production and enhance the overall quality of your product. In this blog, we'll explore how a momo sheeter machine can benefit your business and why it's a must-have for commercial food operations. Be sure to check out our video demonstration to see the machine in action!

What is a Momo Sheeter Machine?

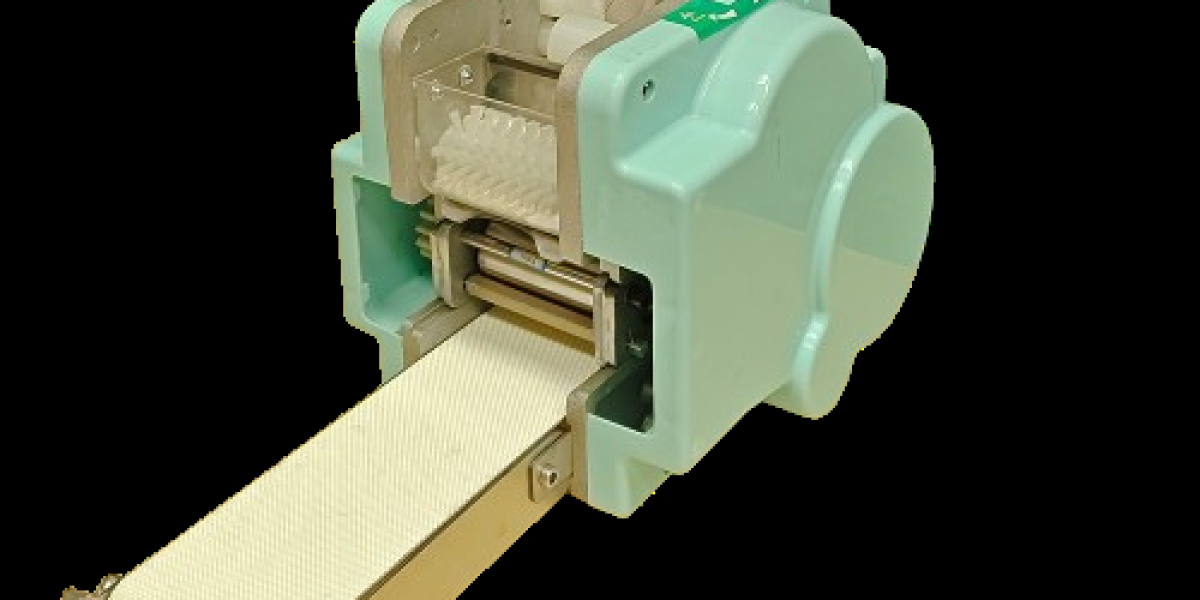

A dumpling wrapper maker is a specialized piece of commercial kitchen equipment that automates the process of rolling dough into thin, even sheets. This machine is ideal for restaurants, catering businesses, and food production facilities that produce large quantities of momos, dumplings, or other similar food items. By automating the dough-rolling process, a momo sheeter machine helps businesses save time, reduce labor costs, and increase production efficiency while maintaining a consistent quality standard.

Why Choose a Momo Sheeter Machine for Your Business?

1. Increase Production Capacity

Manually rolling dough for momos is a time-consuming and labor-intensive task. With a dumpling wrapper machine, this process becomes fully automated, allowing you to produce large volumes of dough sheets in a fraction of the time. Whether you're running a restaurant or a large-scale food production facility, a momo sheeter machine can significantly increase your production capacity, enabling you to meet growing customer demand without compromising on quality.

For businesses looking to expand their operations or cater to a larger customer base, this increased efficiency is critical. Instead of manually rolling dough, which can be inconsistent and slow, the Momo Sheeter Machine ensures uniform, perfectly rolled dough every time, enabling you to keep up with the fast-paced demands of the food industry.

2. Ensure Consistency and Quality

One of the most important factors in food production is consistency. Customers expect their momos to have the same taste, texture, and appearance every time they order. With manual dough rolling, variations in thickness and size can result in inconsistencies in the final product. A Momo Sheeter Machine eliminates this issue by delivering perfectly rolled, uniform dough sheets every time.

Consistency in dough thickness ensures that the momos cook evenly, have a consistent texture, and maintain their visual appeal. This machine guarantees that your momos will always meet the same high-quality standards, which can enhance your brand reputation and encourage repeat business.

3. Reduce Labor Costs

Labor is one of the most significant expenses in any food production business. By automating the dough-rolling process with a momo sheeter machine, you can reduce the amount of manual labor required, freeing up your staff to focus on other tasks such as filling and shaping the momos, cooking, or customer service.

Not only does this reduce labor costs, but it also makes your kitchen operations more efficient. With a momo sheeter machine doing the bulk of the dough preparation work, your employees can focus on higher-value tasks, helping to boost overall productivity.

4. Versatility for Different Dough-Based Products

While the machine is named a Momo Sheeter Machine, its functionality extends far beyond just producing momo wrappers. The machine can be used for a variety of dough-based products, including dumplings, wontons, samosas, and spring rolls. This versatility makes the machine a valuable investment for businesses that produce multiple types of dough-wrapped food items.

By using the same machine for various products, you can streamline your kitchen operations and reduce the need for multiple pieces of equipment. This not only saves space but also cuts down on equipment maintenance costs.

5. Compact Design for Easy Integration

Space is often a premium in commercial kitchens, especially in busy restaurants or food production facilities. The Momo Sheeter Machine from Chef’s Shop is designed with a compact footprint, making it easy to integrate into your existing kitchen setup without taking up excessive space. Its user-friendly design ensures that it can be operated with minimal training, allowing your staff to start using it quickly and efficiently.

6. Hygienic and Easy to Clean

In the food industry, hygiene and food safety are of the utmost importance. The Momo Sheeter Machine is designed with easy-to-clean components that ensure it meets food safety standards. After a long day of production, the machine can be quickly disassembled for cleaning, ensuring that it’s ready for the next day’s operations. The machine’s stainless steel body and other durable materials make it resistant to wear and tear, ensuring a long lifespan with minimal maintenance.

Key Features of Chef's Shop Momo Sheeter Machine

At Chef’s Shop, we offer momo sheeter machines that are equipped with cutting-edge features tailored to the needs of commercial food businesses:

- High Production Capacity: Produce large quantities of dough sheets quickly and efficiently.

- Adjustable Thickness Settings: Customize the thickness of the dough to suit different products, whether you're making momos, dumplings, or other dough-based items.

- Durable and Long-Lasting: Built from high-quality materials that ensure longevity, even with continuous use in busy kitchens.

- Energy Efficient: Despite its powerful performance, the momo sheeter machine is designed to be energy efficient, helping you reduce operational costs.

- User-Friendly Interface: Easy to operate, even for staff with minimal technical experience.

- Compact Size: Fits seamlessly into commercial kitchens of any size.

Who Should Invest in a Momo Sheeter Machine?

The Momo Sheeter Machine is ideal for businesses of all sizes, from small restaurants and catering businesses to large-scale food manufacturers. If your business produces momos, dumplings, or similar food items on a regular basis, this machine can help you improve efficiency, consistency, and profitability.

It is especially beneficial for:

- Restaurants: For restaurants with a high demand for momos or dumplings, the momo sheeter machine can help meet customer expectations by speeding up production without sacrificing quality.

- Catering Companies: Caterers often need to produce large quantities of food in a short amount of time. A momo sheeter machine allows you to quickly produce dough sheets for events, weddings, and large orders.

- Food Production Facilities: For large-scale operations, the momo sheeter machine helps ensure consistent quality and reduces labor costs, making it easier to scale production.

Watch the Momo Sheeter Machine in Action

Want to see how the Momo Sheeter Machine can transform your kitchen operations? Watch our video demonstration to see the machine in action. You'll get a firsthand look at its capabilities, ease of use, and how it can streamline your dough preparation process.

Conclusion

The Momo Sheeter Machine from Chef’s Shop is an essential investment for any business involved in momo production. By automating the dough-rolling process, this machine boosts production capacity, ensures consistency, reduces labor costs, and improves overall efficiency. Whether you run a small restaurant or a large food production facility, this machine will help you meet growing customer demand while maintaining the highest standards of quality.

Ready to take your momo production to the next level? Contact Chef’s Shop today to learn more about our Momo Sheeter Machines or to place your order. Don’t forget to check out our video demonstration to see the machine in action!