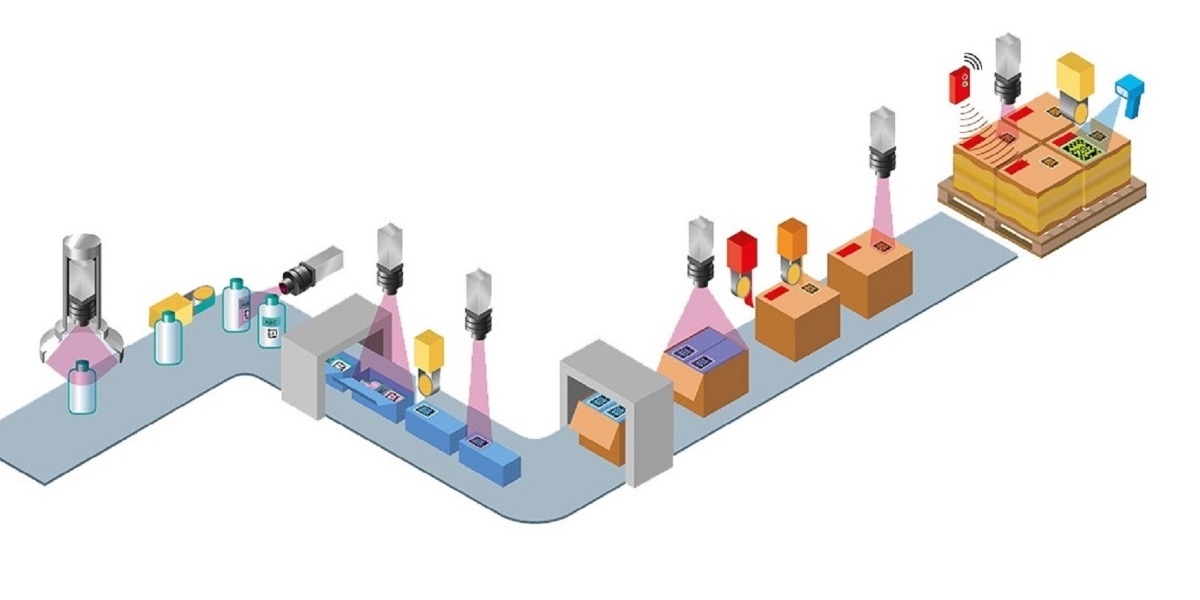

Track and trace solutions utilize various technologies such as barcodes, RFID, sensors and blockchain to uniquely identify items and collect data at different stages of the supply chain. This data is then analyzed to gain valuable insights into inventory levels, transportation routes, storage conditions and more. By gaining real-time visibility, companies can optimize operations, reduce costs and deliver a superior customer experience.

Barcodes

One of the earliest and most widely used track and trace technologies is barcodes. Barcodes store identifier information such as product codes in a machine-readable format. Barcode scanners automatically capture this data and transmit it to backend databases and software systems. While barcodes provide a basic level of item-level tracking, they have limitations. Barcode labels can be damaged, obscuring the code. Line-of-sight scanning is also required. However, for low-cost tracking of packaged goods, barcodes remain useful.

RFID Technology

Radio-frequency identification (RFID) tags overcome some of the key limitations of barcodes. RFID tags have a integrated circuits that can be programmed with unique identifiers and other relevant information. They can be read from a distance without direct line-of-sight, even if they are concealed inside cartons or pallets. Active RFID tags have an inbuilt battery allowing reading over longer ranges. Passive RFID tags derive power from reader signals within range. As RFID technology has become more affordable in recent years, more companies are adopting it for advanced track and trace of high-value items and temperature-sensitive pharmaceuticals.

Sensor Technology

Sensor technologies enable real-time monitoring of environmental and physical conditions throughout transportation and storage. Common sensors track factors like temperature, humidity, light exposure, vibration and shocks. Data loggers store time-stamped sensor readings that can be analyzed later. Temperature sensors ensure temperature-controlled shipments stay within acceptable ranges. Shock and vibration sensors detect mishandling of fragile goods. By integrating sensors with RFID or NFC tags, individual items can be monitored while in transit or storage. This helps identify exact causes of any quality issues.

Blockchain for Supply Chain Visibility

Blockchain distributed ledgers provide a secure and immutable record of each transaction involving an item as it moves through the supply chain. Every entity in the network such as manufacturers, distributors and logistics partners can view and add updates to the shared ledger. This level of transparency builds trust. Smart contracts enable automatic processing of payments, documentation and other activities. Integrating blockchain with IoT devices and sensors creates a digital record linking the physical and digital identities of items. This facilitates seamless track and trace from source to consumption.

Get More Insights On This Topic: Track and Trace Solutions