Butadiene, a versatile chemical compound derived from petroleum refining and natural gas processing, plays a vital role in the production of various polymers and synthetic rubber. Its unique properties make it a cornerstone of the petrochemical industry, with diverse applications across multiple sectors.

Understanding Butadiene:

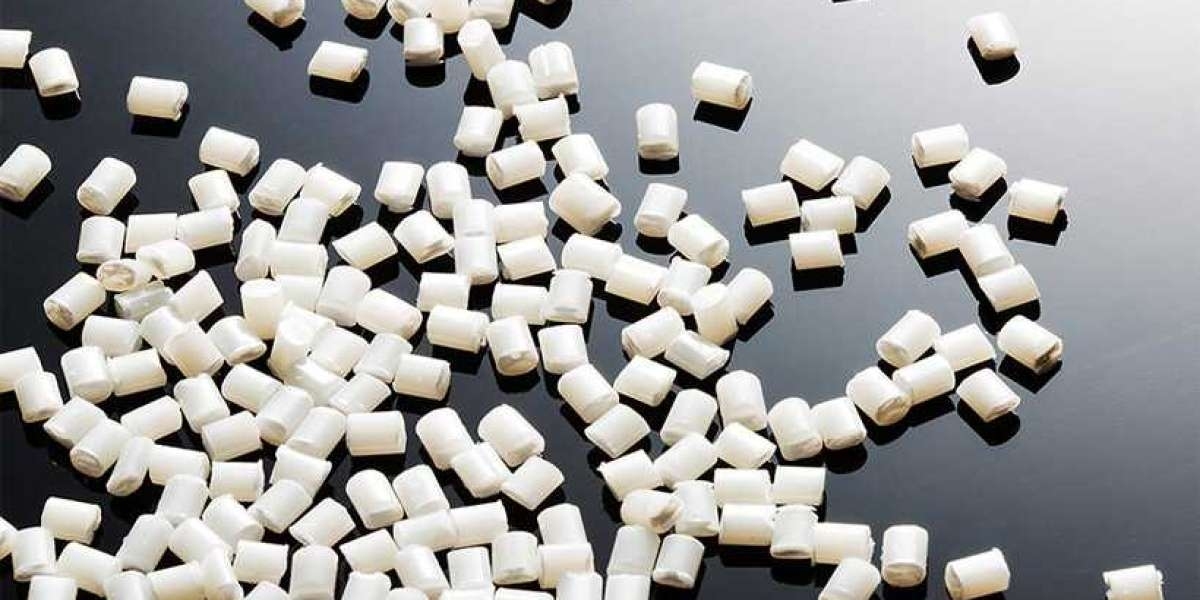

Butadiene, with the chemical formula C4H6, is a colorless, flammable gas that belongs to the family of unsaturated hydrocarbons known as alkenes. It is primarily produced through the steam cracking of hydrocarbon feedstocks such as naphtha, ethane, and propane. Butadiene is valued for its ability to undergo polymerization reactions, forming long chains of repeating units that give rise to synthetic rubber, thermoplastic elastomers, and various plastics.

Applications in Polymer Production:

One of the primary uses of Butadiene is in the production of synthetic rubber, particularly styrene-butadiene rubber (SBR) and polybutadiene rubber (PBR). SBR is widely used in tire manufacturing due to its excellent abrasion resistance and low rolling resistance, while PBR finds applications in conveyor belts, footwear, and automotive parts. Additionally, butadiene is a key monomer in the production of acrylonitrile-butadiene-styrene (ABS) resins, which are used in consumer electronics, automotive interiors, and household appliances.

Growing Demand in Emerging Industries:

As global industries continue to evolve, the demand for butadiene is expanding into new and emerging sectors. The automotive industry, in particular, presents significant growth opportunities for butadiene-based products, driven by increasing vehicle production and the growing adoption of electric and hybrid vehicles. Butadiene-based elastomers and plastics play a crucial role in automotive components such as tires, seals, hoses, and gaskets, contributing to improved performance, fuel efficiency, and safety.

Innovation and Sustainability:

Innovation in butadiene production technologies is also driving growth and sustainability within the industry. Advancements in catalytic cracking and bio-based processes are enabling more efficient and environmentally friendly methods of butadiene synthesis. Additionally, efforts to recycle and repurpose butadiene-containing materials are reducing waste and promoting circular economy principles. By embracing innovation and sustainability, the butadiene industry is poised to meet the evolving needs of a changing world.