Nowadays, the logistics and supply chain industry is taking the opportunity to adopt artificial intelligence at a very large scale. The core objective of leveraging AI in SCM is to boost productivity and increase efficiency. With diverse capabilities and huge potential, AI is rapidly revolutionizing traditional supply chain approaches to make the industry more sustainable, and future-ready. In this blog, we will discuss how artificial intelligence controls supply chain disruptions. Let’s get started.

AI-enabled use cases for supply chain management

AI and Analytics-based systems help supply chain businesses with automated and reliable data visual platforms. Let’s have a look at the top 5 AI use cases that efficiently manage supply chain disruptions.

1. Demand forecasting in warehouse management

Demand forecasting refers to data-rich modeling that helps optimize inventory levels, improve customer satisfaction, and manage warehouse operations efficiently. AI-based forecasts also allow warehouse experts to make informed decisions and build effective strategies for inventory stocking. Important use cases of AI-based demand forecasting are:

Data analysis

Inventory Optimization

Statistical forecasting

Collaborative Forecasting

Continuous Monitoring

Resource planning

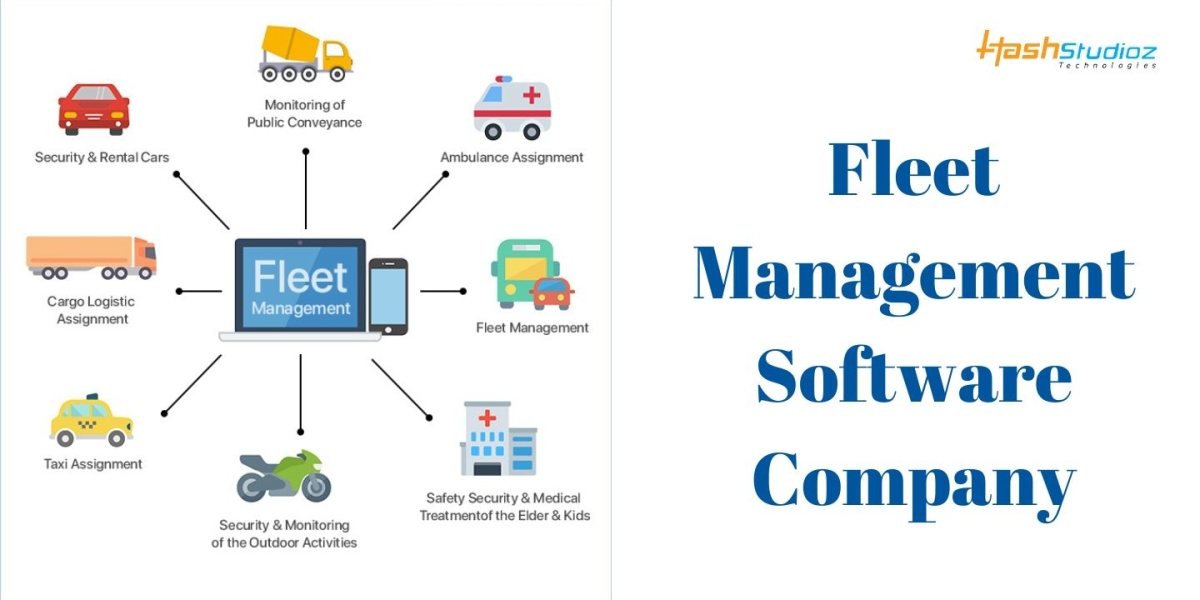

2. AI-based vehicle maintenance

Artificial intelligence helps in vehicle maintenance recommendations by offering data-driven and proactive solutions. This leads to improved vehicle reliability, optimized vehicle maintenance schedules, and minimized downtime. Here is how artificial intelligence is used for vehicle maintenance:

Predictive maintenance

Anomaly Detection

Data Analytics

Cost optimization

Fleet management optimization

Prescriptive maintenance

3. AI in adding portability to the loading process

Supply chain operations involve detail-oriented analysis. This means how goods are loaded or unloaded from the containers. Logistics and supply chain agencies leverage accurate supply chain data analytics and the combination of hardware and software to get real-time visibility into the loading and unloading process. AI significantly improves the portability and visibility of the loading process in the supply chain by managing loading strategies, minimizing errors, and increasing efficiency. Some of the key benefits of AI in adding portability include:

Optimal loading strategies

Predictive analytics

Dynamic load balancing

Visualization & Simulation

Route optimization

Quality control

AI for revenue boost & cost-saving and in supply chain

AI & analytics-based solutions are the cost-effective options that help to minimize procurement and shipping rates and simplify courier contracts efficiently. Moreover, AI provides diverse opportunities for cost savings and revenue growth in supply chain management through automation, optimization & predictive analytics. Let’s have a look at how AI is applied for revenue boost & cost-saving:

Demand forecasting

Supply Chain Network (SCN) optimization

Inventory optimization

Predictive maintenance

Warehouse automation

Quality control

5. Strategic sourcing in the supply chain

AI-based data analytics helps in strategic sourcing and allows organizations to make well-informed decisions, improve cost savings, and manage supplier relationships.

Let’s have a look at how data analytics is applied in strategic sourcing:

Supplier Performance Analysis

Market Intelligence

Cost Analysis

Risk Management

Demand Forecasting

Performance Benchmarking

Supplier Relationship Management

Contract Management

Steps to optimize AI in logistics and supply chain?

Based on the organization’s requirements, industrial environments, and resource availability, the process of AI implementation in the supply chain differs. If you have unique AI business ideas for your logistics services, this guide will help you understand each step clearly. Let’s have a look at the key steps to optimize AI ML in manufacturing or supply chain management.

Step 1: Defining objectives and goals

Trusted AI development companies usually start AI implementation by defining all project objectives and creating goals. Whether it’s optimizing logistics operations or enhancing inventory management, having a clear objective is essential for any business. It helps AI experts determine which field like demand forecasting, inventory optimization, route optimization, or risk management, artificial intelligence will be utilized in.

Step 2: Assess Data Quality

After that, you have to gather information including inventory records, previous datasets, inventory records, and customer info from diverse sources, and organize it properly. You should also collect information from other external sources such as market trends, weather patterns, etc. Moreover, you have to ensure that all information is precise and helpful for AI model training. This is because inadequate data contributes to unreliable predictions and undesired results.

Step 3: Data Preparation & Governance

Raw data comes with several errors, missing values, and inconsistencies. Data preparation entails a number of activities like erasing duplicates, fixing errors, formatting data, addressing missing info, etc. In addition, you have to build data governance to carefully manage data quality. This may include data cleaning, validation, regular audits, etc.

Step 4: Choose an appropriate AI model

After data preparation, you have to choose the right AI model to address key challenges in logistics and supply chain. To choose the right model, you have to consider a few important factors including deep learning, clustering, classification, regression, etc. Apart from that, you need to choose several AI-based technologies like robotic process automation, computer vision, natural language processing (NLP), predictive analytics, etc.

Step 5: Integrate AI into existing systems

Now, you need to add AI capabilities to your existing system as well as infrastructure. You can integrate AI models into different systems like transportation management systems, warehouse management systems, enterprise resource planning (ERP) systems, etc. You have to ensure that the process of integrating AI into previous systems should be seamless.

Step 6: Conduct testing & validation

Once you have integrated AI models into your system, you have to test it in a proper way. Thorough testing and validation help you determine the dependability, accuracy, and performance of AI algorithms. Depending on the results, you can start improving the AI models efficiently.

Step 7: Continuous Improvement

Implementing AI in logistics and supply chain is a continuous process. Therefore, it’s important to focus on modifications and additional changes in the supply chain operations. Continuous improvement helps to enhance productivity, boost accuracy levels, and improve decision-making. Apart from that, you can also stay updated with the AI trends for more supply chain innovations.

Final words

AI has massive potential to revolutionize logistics and supply chain efficiency.

By leveraging AI-based technologies like predictive analytics, machine learning, and natural language processing, logistics service providers can efficiently unlock actionable insights from large datasets. This leads to improved decision-making at every stage of supply chain operations.

https://admin.shopify.com/store/d7b2f4-60/products/8135032373495