Electrical equipment plays a critical role in the operation of crushing plants, powering essential components such as crushers, screens, conveyors, and control systems. Ensuring the normal operation of electrical equipment is paramount for maintaining productivity, safety, and efficiency in industries like mining, construction, and recycling.

Thorough Inspection and Maintenance

Regular inspection and maintenance of electrical equipment are fundamental for ensuring its normal operation and longevity. Implementing a proactive maintenance schedule that includes routine inspections, testing, and preventive maintenance measures helps identify and address potential issues before they escalate into costly failures. Inspecting electrical connections, cables, switches, and control panels for signs of wear, damage, or overheating enables early detection of abnormalities and ensures safe and reliable operation of the concrete crusher for sale.

Compliance with Electrical Standards and Regulations

Adhering to electrical standards and regulations is essential for ensuring the safe and compliant operation of electrical equipment in crushing plants. Following guidelines established by regulatory bodies such as the National Electrical Code (NEC) and Occupational Safety and Health Administration (OSHA) helps mitigate electrical hazards, prevent accidents, and ensure workplace safety. Compliance with standards governing equipment installation, wiring practices, grounding, and electrical protection measures safeguards personnel and equipment from electrical risks.

Proper Installation and Wiring Practices

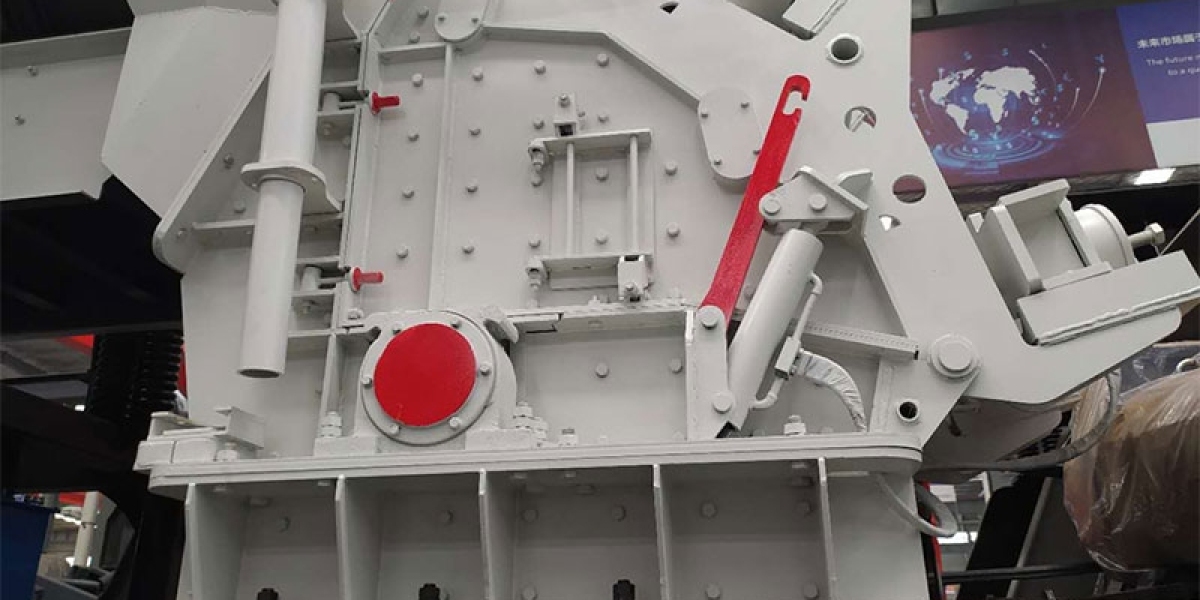

Proper installation and wiring practices are crucial for the reliable operation of electrical equipment in mobile impact crushing plants. Ensuring correct equipment installation, cable routing, and wiring connections minimize the risk of electrical faults, short circuits, and malfunctions. Employing qualified electricians and adhering to manufacturer guidelines and wiring diagrams during installation procedures prevent wiring errors, voltage drop issues, and electromagnetic interference, ensuring optimal electrical performance.

Regular Testing and Troubleshooting

Regular testing and troubleshooting procedures help identify and rectify electrical problems that may affect the normal operation of crushing plant equipment. Conducting periodic electrical tests, such as insulation resistance testing, continuity checks, and voltage measurements, verifies equipment integrity and identifies potential faults or deficiencies. Implementing systematic troubleshooting protocols enables prompt diagnosis and resolution of electrical issues, minimizing downtime and ensuring uninterrupted plant operation.

Grounding and Surge Protection Measures

Proper grounding and surge protection measures are essential for safeguarding electrical equipment from transient voltage surges, lightning strikes, and electrical disturbances. Establishing effective grounding systems and surge protection devices helps dissipate excess voltage, prevent equipment damage, and protect against electrical hazards. Installing surge protectors, transient voltage suppressors, and lightning arrestors at critical points within the electrical distribution system enhances equipment reliability and minimizes the risk of damage from electrical surges.

Training and Education for Personnel

Providing comprehensive training and education for personnel operating and maintaining electrical equipment is crucial for ensuring its normal operation. Training programs should cover topics such as electrical safety practices, equipment operation procedures, emergency response protocols, and preventive maintenance techniques. Equipping personnel with the knowledge and skills to identify potential electrical hazards, troubleshoot common issues, and perform routine maintenance tasks enhances safety awareness and promotes effective equipment management.

Remote Monitoring and Control Systems

Implementing remote monitoring and control systems enables real-time monitoring of electrical equipment parameters, performance metrics, and operating conditions in crushing plants. Remote monitoring platforms facilitate proactive equipment management by providing instant notifications of abnormal conditions, alarms, or faults. Integrating remote control features allows operators to remotely adjust equipment settings, troubleshoot issues, and initiate corrective actions, ensuring continuous and efficient plant operation.

Conclusion

Ensuring the normal operation of electrical equipment in crushing plants requires a multifaceted approach that encompasses thorough inspection and maintenance, compliance with standards, proper installation and wiring practices, regular testing and troubleshooting, grounding and surge protection measures, training for personnel, and implementation of remote monitoring systems. By adopting these strategies and best practices, operators can mitigate electrical risks, enhance equipment reliability, and maintain uninterrupted production in crushing plant operations. Prioritizing electrical equipment safety and reliability fosters a safe work environment, protects personnel and assets, and maximizes the efficiency and productivity of crushing plant operations.