In the realm of manufacturing, mobility and precision are key factors in achieving efficient and high-quality welding results. Handheld laser welders have emerged as a groundbreaking technology, offering welders the freedom to move seamlessly across workpieces while maintaining unparalleled precision. In this blog, we'll delve into the world of handheld laser welders, exploring their unique advantages and applications that are reshaping welding practices across industries.

Unveiling Handheld Laser Welders: A Revolution in Welding Mobility

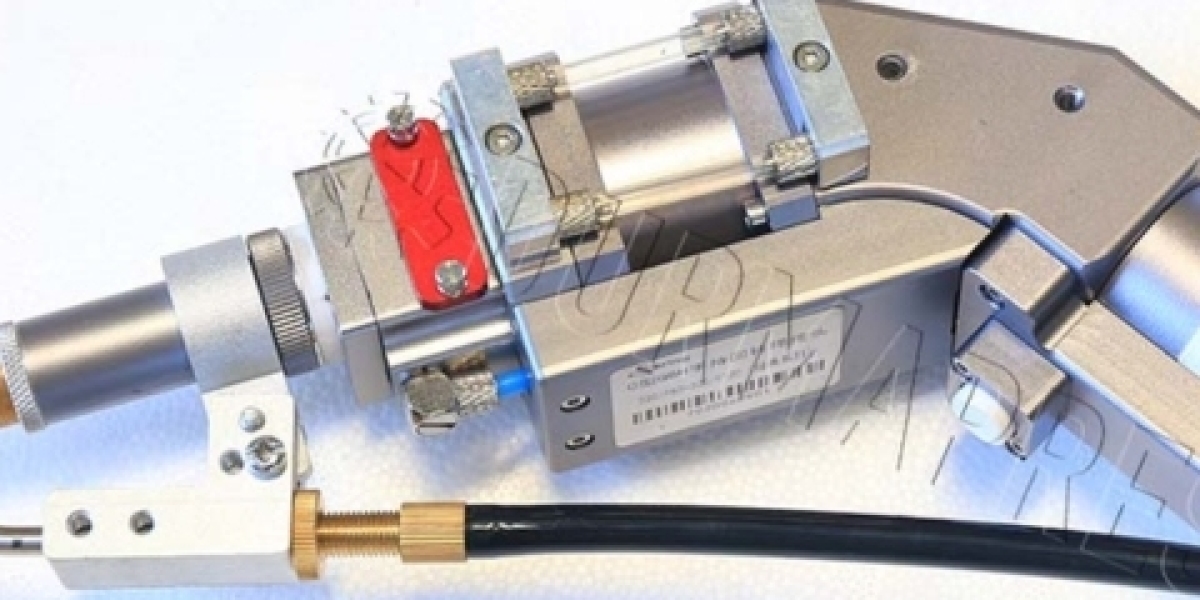

Handheld laser welders represent a significant advancement in welding technology, empowering welders to bring precision welding capabilities directly to the workpiece. Unlike traditional welding methods that require fixed setups and cumbersome equipment, handheld laser welders offer unparalleled flexibility and mobility. Equipped with compact, lightweight designs and ergonomic handles, handheld laser welders allow welders to access tight spaces and maneuver effortlessly, making them ideal for a wide range of welding applications.

Advantages of Handheld Laser Welders

Mobility and Flexibility: Handheld laser welders offer unparalleled mobility and flexibility, allowing welders to access difficult-to-reach areas and maneuver around complex workpieces with ease. The compact, lightweight design of handheld laser welders enables welders to move freely without being tethered to fixed equipment setups.

Precision and Control: Handheld laser welders provide precise control over the welding process, enabling welders to achieve clean, uniform welds with exceptional accuracy. The focused laser beam allows for precise targeting of the weld area, resulting in minimal heat-affected zones and distortion.

Versatility Across Industries: Handheld laser welders find applications across a wide range of industries, including automotive, aerospace, electronics, and medical device manufacturing. Whether it's welding thin sheet metal in automotive body repair or joining delicate components in electronics assembly, handheld laser welders offer the versatility to meet the unique needs of each industry.

Ease of Use: Handheld laser welders are designed for ease of use, with intuitive controls and ergonomic handles that minimize operator fatigue. The user-friendly interface of handheld laser welders allows welders to quickly adapt to the equipment and focus on achieving optimal welding results.

Applications of Handheld Laser Welders

Automotive Body Repair: Handheld laser welders are widely used in automotive body repair for welding thin sheet metal and repairing damage to vehicle panels. The mobility and precision of handheld laser welders enable technicians to perform precise welds without the need for extensive disassembly or panel replacement.

Aerospace Maintenance and Repair: In the aerospace industry, where access to confined spaces and complex geometries is common, handheld laser welders offer a solution for performing maintenance and repair tasks with precision and efficiency. Handheld laser welders enable technicians to weld critical components with minimal disruption to aircraft operations.

Electronics Assembly and Repair: Handheld laser welders are utilized in electronics manufacturing for joining small and delicate components with micron-level accuracy. Whether it's repairing circuit boards or assembling electronic devices, handheld laser welders offer the flexibility and precision required for intricate soldering and welding tasks.

Medical Device Fabrication: In the medical industry, where precision and cleanliness are paramount, handheld laser welders are used to weld components such as surgical instruments, implants, and medical devices. The mobility and precision of handheld laser welders make them ideal for performing delicate welding tasks in sterile environments.

Conclusion: Empowering Welders with Precision Mobility

In conclusion, handheld laser welders represent a transformative advancement in welding technology, offering unparalleled mobility, precision, and versatility. Whether it's automotive body repair, aerospace maintenance, electronics assembly, or medical device fabrication, handheld laser welders empower welders to achieve superior welding results with ease and efficiency. By embracing the capabilities of handheld laser welders, manufacturers can elevate their welding practices to new levels of excellence and meet the demands of today's dynamic manufacturing landscape.