In the ever-evolving landscape of industrial adhesives, epoxy adhesives have emerged as the unsung heroes, silently but significantly revolutionizing various industries. The epoxy adhesives market is not merely witnessing growth; it is experiencing a revolution driven by relentless innovations. In this blog, we delve into the groundbreaking advancements propelling the epoxy adhesives industry and reshaping market dynamics.

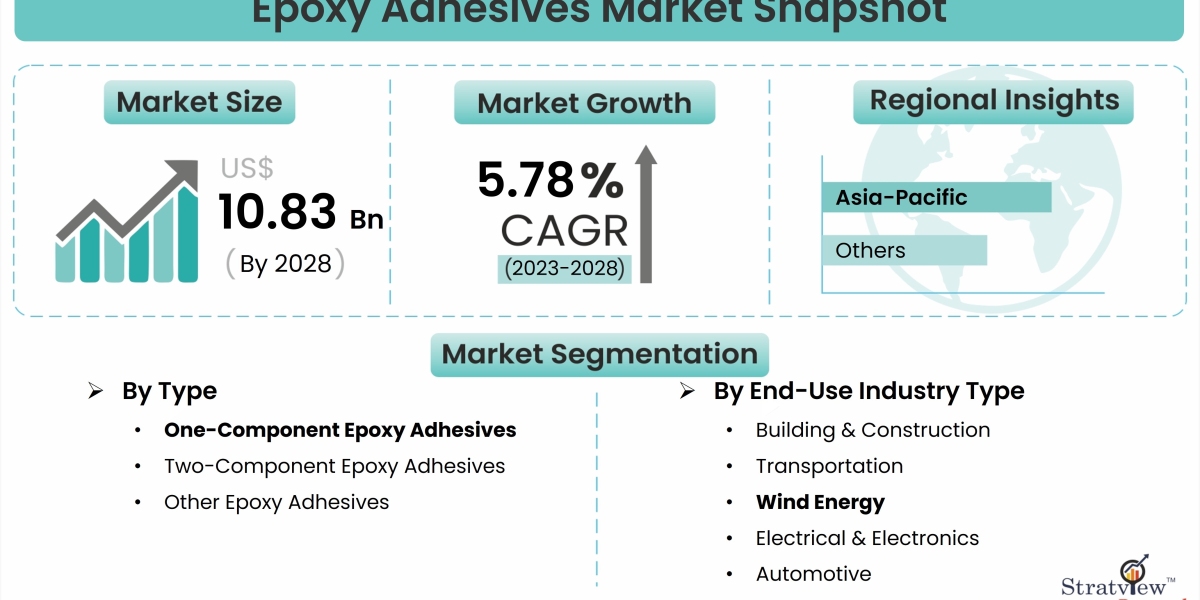

According to Stratview Research, Epoxy Adhesives Market is expected to grow from USD 7.73 billion in 2022 to USD 10.83 billion by 2028 at a healthy CAGR of 5.78% during the forecast period of 2023-2028 .

Epoxy adhesives are copolymers that are formed by the process of mixing a resin and a hardener. Epoxy adhesives offer excellent features such as high strength, capacity to adhere to a wide variety of materials, and chemical and environmental resistivity, due to which they are the most widely used structural adhesives.

These adhesives are available in different forms such as one-component, heat-curing two-component, and room-temperature curing systems.

To learn more about the report, click here:

https://www.stratviewresearch.com/964/epoxy-adhesives-market.html

Unleashing the Power of Nanotechnology: Stronger Bonds, Smaller Scale

At the forefront of the epoxy adhesives revolution is the integration of nanotechnology. Nanoparticles, often measured in billionths of a meter, are being incorporated into epoxy formulations to enhance their performance on a molecular scale. This innovation is unlocking unprecedented strength, durability, and versatility in epoxy adhesives.

Nanoparticles, such as nanoclays or carbon nanotubes, reinforce the adhesive matrix, creating bonds that are not only stronger but also more resilient to factors like temperature extremes and mechanical stress. This nanoscale revolution is particularly significant in industries where lightweight yet robust bonding solutions are paramount, such as aerospace and automotive manufacturing.

Smart Adhesives: A New Frontier in Epoxy Technology

In the era of smart materials, epoxy adhesives are stepping into the spotlight with the development of smart adhesives. These adhesives are not just passive bonding agents; they come equipped with integrated sensors and functionalities that transform them into active components within a system.

Imagine an epoxy adhesive that not only securely bonds two surfaces but also monitors stress, temperature, or structural integrity. This innovation is especially relevant in structural applications, enabling real-time monitoring and preventive maintenance. The integration of smart adhesives aligns with the broader trend of Industry 4.0, where connectivity and data-driven decision-making redefine manufacturing processes.

Bio-Based Resins: Epoxy Adhesives Go Green

Sustainability is no longer a buzzword but a driving force shaping the choices consumers and industries make. In response to the growing demand for environmentally friendly solutions, the epoxy adhesives industry is undergoing a green revolution with the development of bio-based resins.

Derived from renewable sources such as plant oils or sugars, bio-based epoxy resins offer a sustainable alternative to traditional petrochemical-based counterparts. This innovation not only reduces the industry's reliance on fossil fuels but also aligns epoxy adhesives with the principles of circular economy and reduced environmental impact.

Rapid Cure Technologies: Time as a Competitive Advantage

In manufacturing, time is money, and rapid cure technologies are transforming epoxy adhesives into time-saving assets. Traditional epoxy formulations often required extended curing times, limiting their efficiency in fast-paced production environments. The advent of rapid cure technologies addresses this limitation, allowing for quicker bonding and assembly processes.

Whether in automotive assembly lines or electronic device manufacturing, the ability to achieve strong bonds in a fraction of the time enhances overall production efficiency. This innovation not only meets the demands of modern manufacturing but also opens up new possibilities for industries with stringent time constraints.

Toughened Epoxies: A Shift from Brittle to Ductile

The inherent brittleness of traditional epoxy formulations has been a historical challenge, particularly in applications where impact resistance is critical. The epoxy adhesives revolution includes the development of toughened epoxies, marking a shift from brittle to ductile characteristics.

Toughened epoxies incorporate additives or modifiers that enhance flexibility and impact resistance without compromising other desirable properties like strength and adhesion. This innovation expands the application scope of epoxy adhesives into areas where the ability to absorb energy and withstand sudden forces is crucial, such as in the assembly of consumer electronics or transportation components.

Customized Formulations: Tailoring Solutions for Every Application

As industries become more specialized and diverse, the demand for customized adhesive solutions is on the rise. The epoxy adhesives revolution includes a shift towards tailored formulations that address the unique needs of specific applications.

Manufacturers are investing in research and development to create epoxy adhesives with characteristics fine-tuned for particular industries. This customization extends to considerations such as temperature resistance, chemical compatibility, and bonding strength, ensuring that epoxy adhesives can meet the exacting requirements of industries ranging from healthcare to construction.

3D Printing with Epoxy: Shaping the Future of Manufacturing

The intersection of epoxy adhesives and 3D printing is creating a paradigm shift in manufacturing. Epoxy-based resins are increasingly used as materials for 3D printing, allowing for the creation of intricate and complex structures with precision.

This innovation is particularly significant in industries where prototyping, customization, and rapid production are essential. The ability to 3D print with epoxy opens up new avenues for creativity and efficiency, enabling manufacturers to bring concepts to reality with unprecedented speed and precision.

Conclusion: Epoxy Adhesives at the Vanguard of Innovation

The epoxy adhesives revolution is not a distant vision; it's a dynamic reality shaping the present and future of industrial adhesives. From the nanoscale reinforcement to the integration of smart functionalities, the industry is pushing the boundaries of what epoxy adhesives can achieve. As these innovations continue to drive market dynamics, the role of epoxy adhesives in various industries will only become more pivotal.

Manufacturers, researchers, and end-users alike stand at the vanguard of this revolution, embracing the possibilities that epoxy adhesives offer. Whether it's through stronger bonds at the molecular level, sustainable formulations, or the integration of smart technologies, epoxy adhesives are proven to be not just agents of connection but catalysts for innovation across diverse sectors. The revolution is here, and epoxy adhesives are at the forefront, reshaping the way we build, create, and connect in the modern world.

About Us

Stratview Research is a global market research firm, offering syndicated and custom research reports and growth consulting services. Our business intelligence and industry research reports offer clients insightful market data to aid strategic decision-making. These exclusive reports are the result of exclusive research methodology and are available for key industries such as chemicals, composites, advanced materials, technology, renewable energy, and more.

Stratview Research delivers custom research services across sectors. In case of any custom research requirements, please send your inquiry to sales@stratviewresearch.com or connect with our experts at +1-313-307-4176.