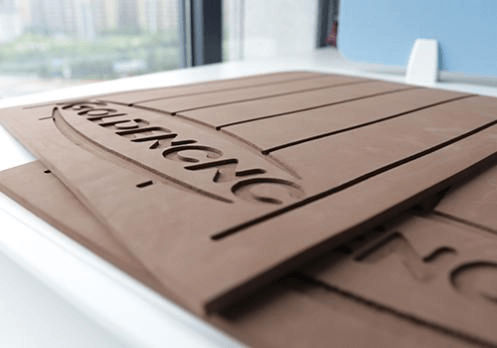

Oscillating knife machine is suitable for cutting various thin flexible materials. The digital cutting machine is designed for small batch production, which can save costs while maintaining speed and accuracy. This digital cutting machine is used in various industries such as packaging, printing, advertising display, leather processing, architectural modeling, composite materials, and tool modeling.

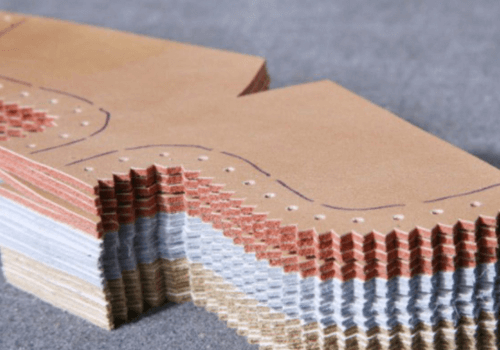

An oscillating knife cutting machine, also known as a CNC oscillating knife cutter, is a specialized cutting tool used in various industries for precision cutting of a wide range of materials. It operates by rapidly moving a knife blade back and forth in an oscillating motion to cut through materials with high precision and minimal material waste. These machines are highly versatile and are used for cutting materials like fabrics, leather, foam, rubber, paper, cardboard, composites, and more.

A vibrating knife option is an important tool for companies that need to process flexible materials. These flexible materials include packaging foam, foam core, blender foam, corrugated plastic, or cardboard. These materials all pose challenges to traditional router planning or cutting tools, but the “saw action” of the oscillating knife makes it easy to cut these materials, providing a clean cutting edge without fraying.

Oscillating Knife Cutting Machine Advantages

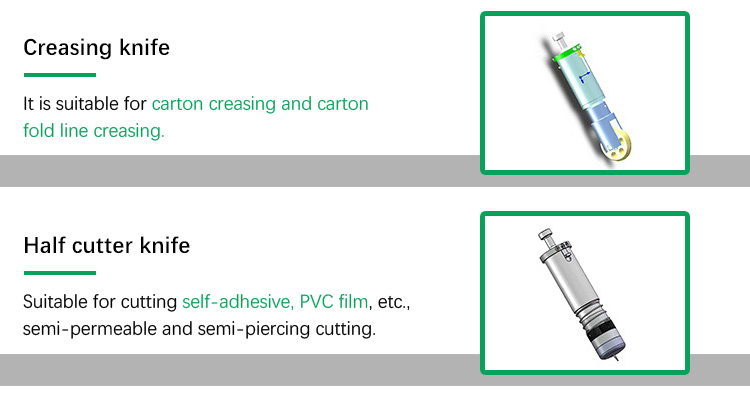

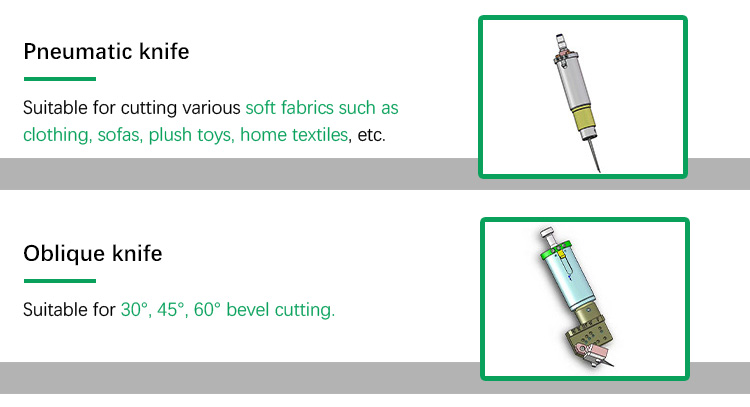

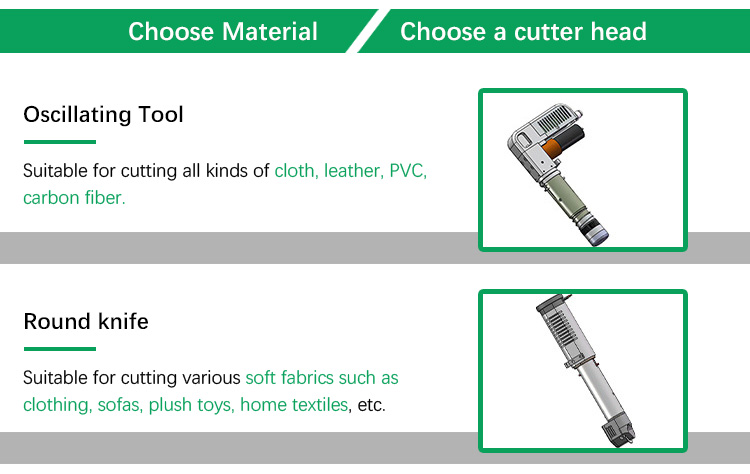

- Knife Options: These machines can be equipped with various knife types, including straight blades, serrated blades, V-shaped blades, and more, depending on the specific material and cutting requirements.

- Precision: Oscillating knife cutters offer high precision and can cut intricate shapes, patterns, and curves with sharp corners. This makes them well-suited for industries that require intricate or custom designs.

- Software and Design: Design your cutting patterns using computer-aided design (CAD) or computer-aided manufacturing (CAM) software. The machine’s software then translates these designs into cutting paths.

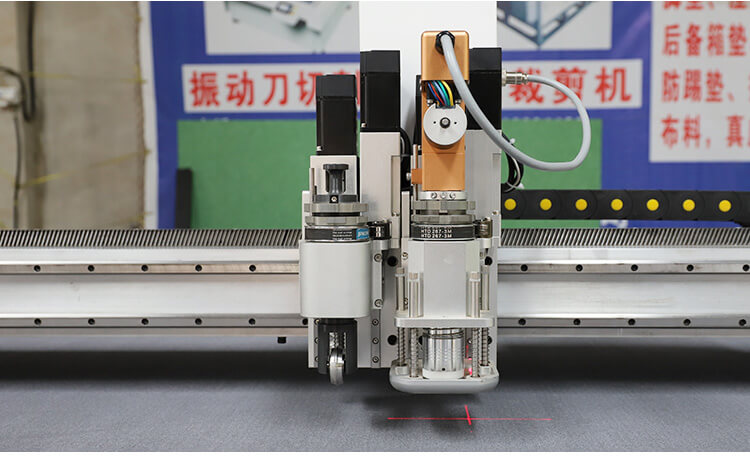

- Tool Control: Many oscillating knife cutters come with multiple toolheads, allowing for different tools to be used in one machine. For instance, you can use a knife for cutting, a creasing tool for scoring, or a pen for marking.

- Depth and Speed Control: Adjust the cutting depth and cutting speed to match the material you’re working with. Different materials may require different settings for optimal results.

- Material Hold-Down: These machines often use vacuum tables, conveyor systems, or other methods to hold down the material during cutting, ensuring precision and preventing material shift.

Applicable materials of oscillating knife cutting machine:

Oscillating knife machine is suitable for cutting various thin flexible materials. The digital cutting machine is designed for small batch production, which can save costs while maintaining speed and accuracy. This digital cutting machine is used in various industries such as packaging, printing, advertising display, leather processing, architectural modeling, composite materials, and tool modeling.

Leather,sticker,cardboard,Plastic box,corrugated cardboard,film,foam board,acrylic board,rebound rubber,rubber cloth,gasket material,garment cloth,footwear material,bags materials,non-woven fabrics,carpets,sponge,PU,EVA,XPE,PVC,PP,PE,PTFE,ETFE,and composites,whose thickness of above materials is below 22 mm.

Oscillating knife cutting machines are valuable tools for industries that require precision cutting of soft and semi-rigid materials. They offer efficiency, speed, and accuracy, making them suitable for both mass production and custom manufacturing. When used correctly, these machines can improve productivity and the quality of the final products.

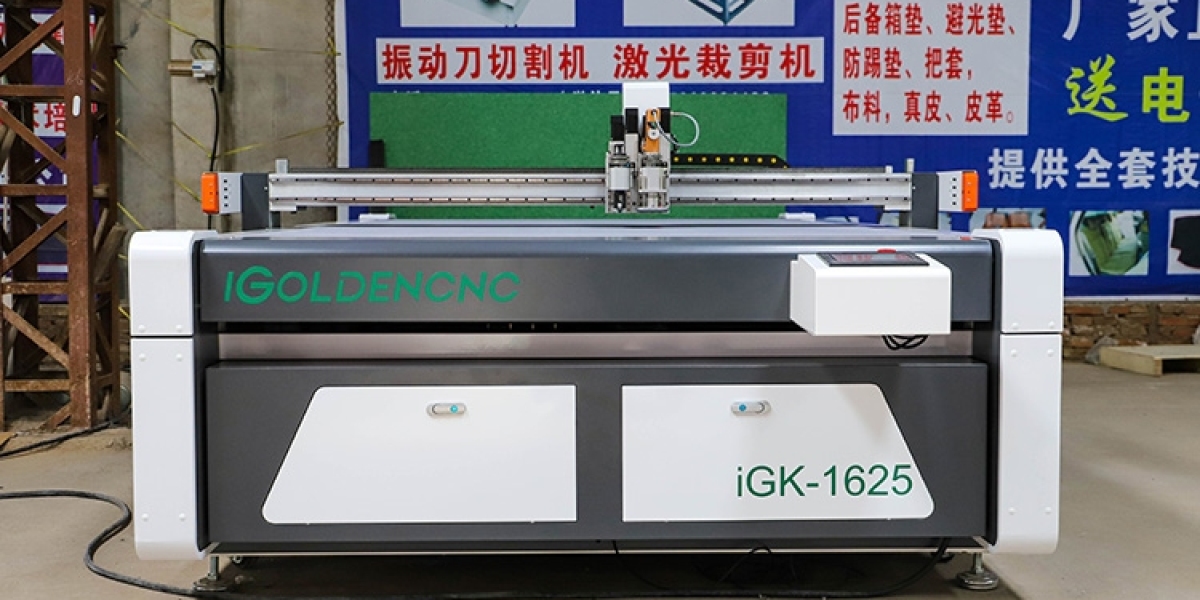

CNC Knife Cutting Machines

Complementing other areas within our cutting machine range, the CNC knife cutting tables bring even greater versatility to the cutting process. These beautifully made, sophisticated machines are produced by one of the largest, specialized manufacturers of CNC cutting tables in the world. This total focus on innovative machines with very elegant software has culminated in a sophisticated range of CNC knife cutting machines which will cut an ever increasing range of materials at maximum speed with minimum waste.

This very wide range of flatbed cutting machines includes models with fixed beds and moving conveyors so that any material format – sheet, roll or a combination of both, can be processed. Ideal for short run, fast response working, these systems are also eminently suitable for full scale production as well as prototyping.

Add to this the large range of cutting tools that can be carried on the multi-tool cutting head – fixed blade, pizza wheel [rotary blade], electric or pneumatic oscillating blade, milling and routing, kiss cut, ultrasonic and pen – and the sheer versatility is clear.

Processing advantages

Automatic feeding system with intelligent correction function

This product uses a full-automatic feeding platform, which realizes the automatic work of feeding and cutting, saving labor costs. With the automatic deviation-feeding system, it can overcome the deformation problem of flexible materials in the printing or embroidery process, intelligently handle the deformation matching, and realize the automatic search Edge cutting.

Cutting tool without pollution

Compared with laser cutting, the cutting speed of the cutter is faster, no odor, and the cutting edge will not be carbonized. It is especially suitable for cutting intimate apparel such as swimwear and cycling clothes. Customers can also configure different types of tools according to the cutting material to meet the processing of different materials.

Automatic edge-finding and precise cutting

This product applies the industry’s advanced precise visual recognition algorithm and fine numerical control cutting technology. It searches and locates the graphic position through the vision system, controls the precise movement of the cutting head to the corresponding position, and automatically aligns and cuts along the edge with an error of less than 0.5MM.

Automatic operation saves costs

Fully-automatic feeding platform, continuous cutting, no special care required, easy operation; this product supports multiple layout methods, can achieve seamless stitching and cutting of the same graphic, reduce waste consumption; integrate its various high-quality functions, achieve faster speed, save material More and better performance. So as to reduce production costs and improve production efficiency.