In the dynamic landscape of technology and manufacturing, the emergence of biocompatible 3D printing materials is poised to shape the future of innovation. As industries strive for advancements that are not only groundbreaking but also sustainable, the biocompatible materials market stands at the forefront of this transformative journey, promising a tomorrow where customization, efficiency, and ecological responsibility converge.

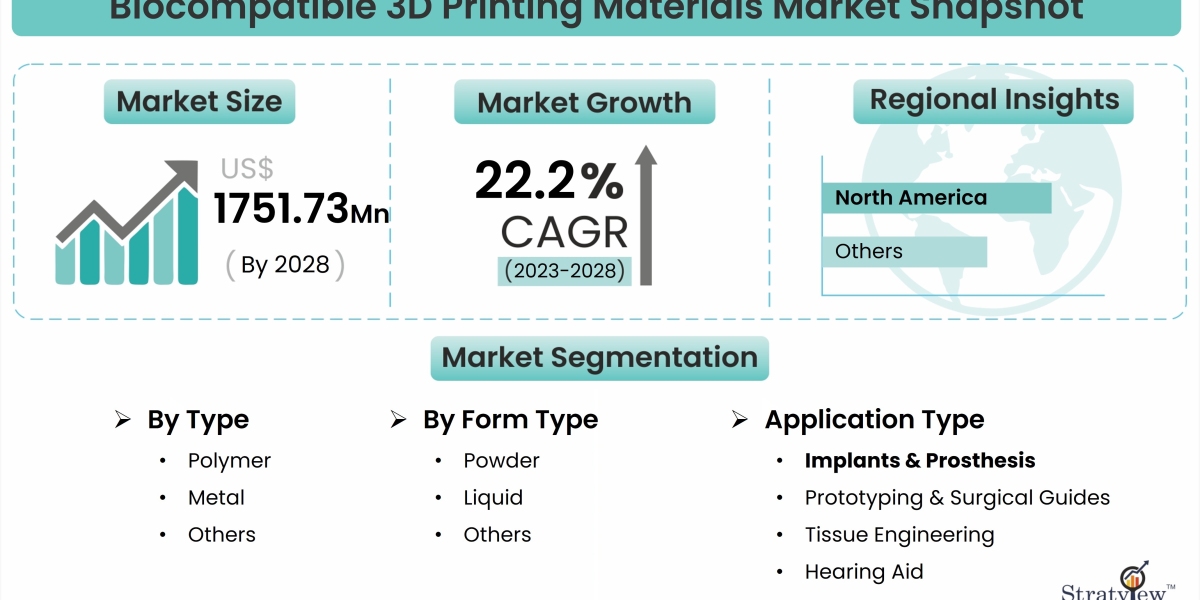

According to Stratview Research, the Global Biocompatible 3D Printing Materials Market is expected to grow from USD 525.85 million in 2022 to USD 1751.73 million by 2028 at a healthy CAGR of 22.2% during the forecast period of 2023-2028 .

Biocompatible 3D printing materials are materials that are low in viscosity and help produce tough parts. These are mainly known for their applications for medical purposes.

Biocompatible 3D printing materials can be of polymer, metal, or others. They are available in powder, liquid, and also in other forms. Implants & prostheses, prototyping & surgical guides, tissue engineering, hearing aids, and others are some of the application areas where these materials are used.

To learn more about the report, click here:

https://www.stratviewresearch.com/702/biocompatible-3d-printing-materials-market.html

The Foundation of a Revolution

At the core of this transformative wave lies 3D printing, a technology that has evolved from a niche application to a driving force behind a myriad of industries. Now, with the integration of biocompatible materials into the 3D printing arsenal, a whole new dimension of possibilities is being unlocked.

Unleashing Customization:

The hallmark of biocompatible 3D printing materials is their ability to be customized for specific applications. Whether it's creating tailored medical implants, personalized consumer products, or intricate industrial components, the versatility of these materials is redefining the meaning of customization in manufacturing.

Beyond Traditional Boundaries:

Unlike conventional manufacturing processes that are often limited by molds and standardized designs, 3D printing allows for the creation of complex structures with unprecedented precision. Biocompatible materials take this a step further by opening doors to applications in medicine, aerospace, automotive, and more.

The Rise of Sustainable Manufacturing

As the world grapples with the consequences of climate change and environmental degradation, the need for sustainable practices in manufacturing has become more pressing than ever. The biocompatible 3D printing materials market is positioned as a key player in this sustainability revolution.

Eco-Friendly Materials:

Many biocompatible materials are derived from renewable resources, such as plant-based polymers and biodegradable compounds. This shift towards eco-friendly materials is not only reducing the reliance on fossil fuels but also mitigating the environmental impact associated with traditional manufacturing processes.

Waste Reduction:

Traditional manufacturing often generates significant waste through subtractive processes. In contrast, 3D printing is an additive process, where materials are deposited layer by layer to create the final product. This not only minimizes material waste but also contributes to the efficiency of the overall manufacturing process.

Localized Production:

The biocompatible 3D printing materials market is enabling a shift towards localized production. By decentralizing manufacturing and producing goods closer to the point of consumption, the carbon footprint associated with transportation and logistics is significantly reduced. This localized approach aligns with the principles of sustainability and economic efficiency.

Applications Across Industries

The versatility of biocompatible 3D printing materials extends across a spectrum of industries, each benefiting from the unique properties these materials bring to the table.

Healthcare:

One of the most profound impacts is witnessed in healthcare. The ability to create patient-specific implants, prosthetics, and even organs through bioprinting has revolutionized the medical field. The biocompatible advantage ensures compatibility with the human body, reducing the risk of rejection and opening new avenues for personalized medicine.

Aerospace and Automotive:

In aerospace and automotive industries, the lightweight and durable nature of biocompatible materials are instrumental. Components can be designed with precision, optimizing fuel efficiency in vehicles and reducing the overall weight of aircraft, leading to enhanced performance and sustainability.

Consumer Goods:

From customized fashion accessories to eco-friendly packaging, the consumer goods sector is tapping into the potential of biocompatible materials. Brands are exploring innovative designs that were once impractical with traditional manufacturing methods, offering consumers unique and sustainable products.

Industrial Manufacturing:

In industrial settings, the use of biocompatible 3D printing materials is streamlining the production of complex components. The ability to create intricate and customized parts on-demand improves efficiency, reduces lead times, and contributes to overall cost-effectiveness.

Challenges and Opportunities on the Horizon

While the biocompatible 3D printing materials market holds immense promise, it is not without its challenges. The need for standardized regulations, material certification, and comprehensive testing protocols are critical factors that must be addressed to ensure the safety and reliability of products manufactured with these materials.

Regulatory Landscape:

The regulatory landscape surrounding biocompatible materials, especially in the medical field, is evolving. Striking the right balance between encouraging innovation and ensuring patient safety is an ongoing challenge. Establishing clear guidelines and standards is essential to foster trust in these revolutionary technologies.

Material Development:

Continuous research and development are necessary to expand the range of biocompatible materials available. This includes not only improving the properties of existing materials but also discovering new compounds that can address specific application requirements.

Looking Ahead: A Future Built on Innovation

As we explore the biocompatible 3D printing materials market, it becomes evident that we are standing at the precipice of a manufacturing revolution. The synergy between 3D printing technology and biocompatible materials is shaping a future where customization, sustainability, and efficiency are no longer mutually exclusive.

Global Collaboration:

The future success of the biocompatible 3D printing materials market relies on global collaboration. Researchers, manufacturers, regulatory bodies, and consumers must work together to navigate the complexities of this evolving landscape. Collaboration will accelerate innovation, address challenges, and ensure the responsible adoption of these technologies.

Educating the Industry:

Education is a key component of this revolution. Industry professionals, from engineers to healthcare practitioners, must stay informed about the capabilities and limitations of biocompatible materials. Training programs and workshops can empower individuals to harness the full potential of these materials in their respective fields.

Conclusion: Building a Sustainable Tomorrow

In conclusion, the exploration of the biocompatible 3D printing materials market is a journey into a future where manufacturing is not just about creating products but about building a sustainable tomorrow. The fusion of customization, efficiency, and ecological responsibility is reshaping industries, offering a glimpse into a world where innovation is synonymous with responsibility.

As we build tomorrow with biocompatible materials, we are not only redefining the possibilities of manufacturing but also laying the foundation for a future where technology serves humanity and the planet. The journey ahead is challenging, but the destination is a world where industries are not just sustainable but actively contribute to the well-being of our planet and its inhabitants. The biocompatible 3D printing materials market is not just a market; it's a pathway to a better and more responsible future.

About Us

Stratview Research is a global market research firm, offering syndicated and custom research reports along with growth consulting services. Our business intelligence and industry research reports offer clients insightful market data to aid strategic decision-making. These exclusive reports are the result of exclusive research methodology and are available for key industries such as chemicals, composites, advanced materials, technology, renewable energy, and more.

Stratview Research delivers custom research services across sectors. In case of any custom research requirements, please send your inquiry to sales@stratviewresearch.com or connect with our experts at +1-313-307-4176.