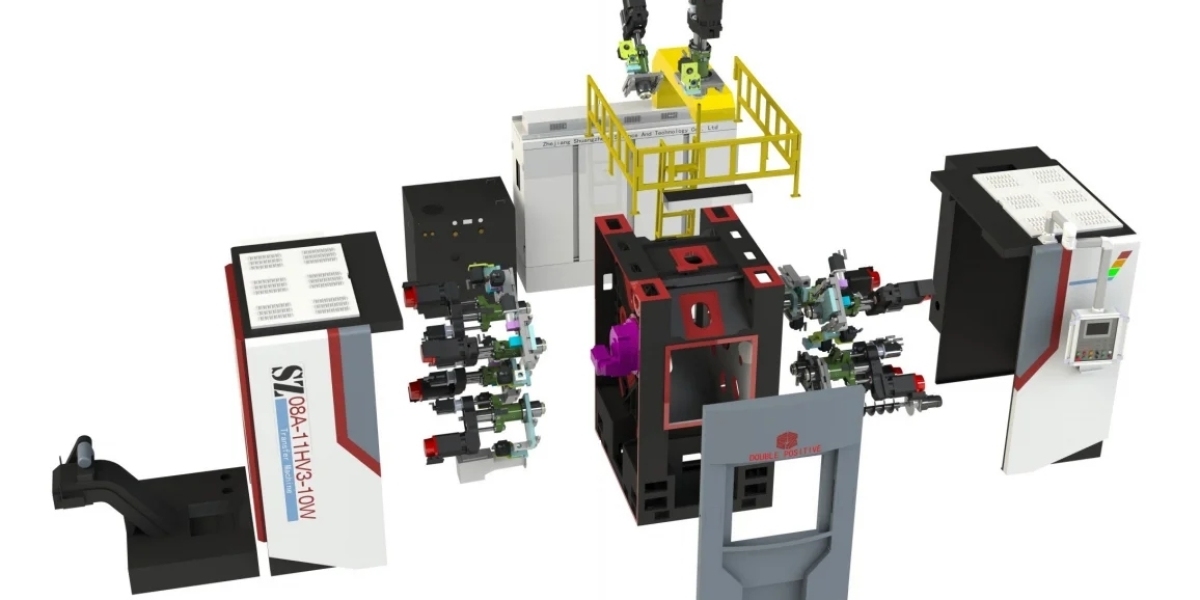

Rotary Table Intelligent Assembly Machine is suitable for all kinds of hard alloy and non-ferrous metal processing, can meet the general shaft, disk, box parts of the internal and external cylinder, cone, sphere, step, groove, various threads, complex surface of continuous processing or single processing. The technical performance has reached the advanced level of similar products in China. How to reduce the machining error of machine tool has become a hot spot in the field of machine tool manufacturing. Aiming at the low machining accuracy of Rotary Table Intelligent Assembly Machine in actual production, methods and measures such as error compensation method and error prevention method are adopted to improve the machining accuracy of the machine tool.

First, error compensation method

Error compensation method is to use the compensation function of the CNC machine tool system to compensate the existing error on the axis of the machine tool, so as to improve the precision of the CNC machine tool. It is an effective and economical method to improve the precision of CNC machine tools. Error compensation can be achieved by hardware or software.

2. Methods to prevent errors

The method of error prevention belongs to pre-prevention, that is, to eliminate the source of error through design, manufacturing and other ways. For example, by improving the machining accuracy of machine parts, improving the rigidity of the machine tool system, improving the structural materials of the machine tool, strictly controlling the processing environment (such as the workshop processing environment), and improving the processing accuracy.

Although "hard technology" is used to prevent errors, its disadvantage is that its performance increases exponentially with cost. At the same time, simply using the method of preventing error to improve the machining accuracy of CNC machine tools, when the accuracy reaches a certain requirement, it is very difficult to improve.

Third, other ways

In order to solve the machining accuracy error caused by the geometric parameters of the tool, the following methods can be adopted: the tool tip trajectory and the machining contour are in line with the ideal contour during programming, that is, the actual arc trajectory is converted into the imaginary tool tip trajectory through manual calculation, so as to achieve the theoretical rationality.

Rotary Table Intelligent Assembly Machine https://www.zjshuangzheng.com/Rotary-Table-Intelligent-Assembly-Machine.html