Introduction

The world of coatings and surface treatments is undergoing a remarkable shift towards sustainability and environmental responsibility. Among the significant advancements in this realm are eco-friendly pretreatment coatings. These coatings not only prepare surfaces for subsequent layers but also do so with reduced environmental impact. In this article, we delve into the world of eco-friendly pretreatment coatings, exploring their benefits, the driving forces behind their rise, and the trends shaping their future.

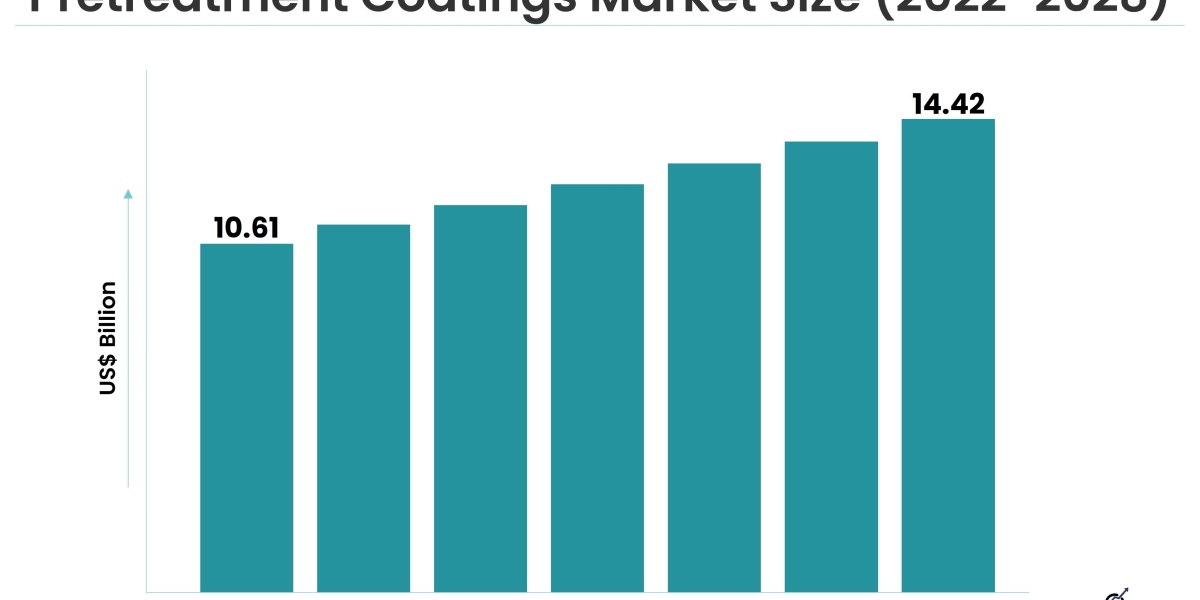

According to Stratview Research, the Pretreatment Coatings Market is expected to grow from USD 10.61 billion in 2022 to USD 14.42 billion by 2028 at a healthy CAGR of 5.20% during the forecast period of 2023-2028.

Growing end-use industries such as aerospace and automotive, and an increase in construction & renovation activities coupled with the change in consumer perceptions regarding utilization of high-quality materials in the construction industry are some of the key factors accelerating the market growth during the forecast period.

To know more about the report, click here:

https://www.stratviewresearch.com/1563/pretreatment-coatings-market.html

The Need for Eco-Friendly Solutions

As industries across the globe strive to reduce their carbon footprint and minimize the use of hazardous materials, the demand for environmentally friendly alternatives has grown exponentially. Traditional pretreatment coatings often rely on solvent-based formulations with high volatile organic compound (VOC) emissions, contributing to air pollution and posing health risks to workers. Eco-friendly pretreatment coatings aim to address these concerns while maintaining the essential functions of their traditional counterparts.

Benefits of Eco-Friendly Pretreatment Coatings

- Reduced VOC Emissions: One of the most significant advantages of eco-friendly pretreatment coatings is their lower VOC content. VOCs contribute to air pollution and have been linked to various health issues. By reducing VOC emissions, these coatings offer a safer and healthier working environment for employees and contribute to overall air quality improvement.

- Environmental Impact: Traditional coatings often contain hazardous chemicals that can leach into the environment during application and disposal. Eco-friendly coatings utilize less harmful ingredients and reduce the potential for soil and water contamination, aligning with the broader goals of sustainable manufacturing and responsible waste management.

- Regulatory Compliance: Stringent environmental regulations and standards have prompted industries to seek coatings that meet compliance requirements. Eco-friendly pretreatment coatings help manufacturers avoid potential legal and financial consequences associated with non-compliance with environmental regulations.

- Energy Efficiency: Some eco-friendly coatings are designed to cure at lower temperatures, reducing the energy required during the application and curing process. This not only lowers energy consumption but also contributes to cost savings for manufacturers.

- Improved Worker Safety: Eco-friendly coatings often have lower toxicity levels, reducing the risk of exposure-related health issues for workers involved in the coating application process.

Trends Shaping the Eco-Friendly Pretreatment Coatings Landscape

- Waterborne Formulations: Waterborne coatings are a staple in the world of eco-friendly pretreatment solutions. They replace traditional solvent-based coatings with water as the primary carrier, significantly reducing VOC emissions. Waterborne coatings are becoming increasingly sophisticated and offer comparable performance to their conventional counterparts.

- Conversion to Non-Toxic Compounds: Researchers and manufacturers are actively exploring ways to replace toxic compounds traditionally used in coatings with safer alternatives. This includes finding substitutes for heavy metals and other harmful chemicals that have been prevalent in pretreatment formulations.

- Nanotechnology Advancements: Nanocoatings, which involve manipulating materials at the nanoscale, are gaining traction in the eco-friendly pretreatment coatings sector. These coatings offer enhanced properties such as improved adhesion, corrosion resistance, and mechanical strength, all while using fewer resources.

- Bio-Based Ingredients: The shift towards bio-based materials is not limited to the food and packaging industries. Eco-friendly coatings are incorporating bio-based ingredients derived from renewable sources, reducing reliance on fossil fuels and lowering the overall carbon footprint.

- Green Certification and Labels: As consumer awareness of sustainability grows, industries are placing a premium on certifications and labels that vouch for the eco-friendliness of their products. Coatings with recognized green certifications can give manufacturers a competitive edge and signal their commitment to environmental responsibility.

The Path Forward

Eco-friendly pretreatment coatings represent a positive trajectory for both industries and the environment. As technology advances and innovation thrives, the performance gap between eco-friendly coatings and traditional formulations continues to narrow. The benefits of reduced environmental impact, improved worker safety, and regulatory compliance make these coatings an attractive choice for manufacturers across various sectors.

As the global emphasis on sustainability intensifies, eco-friendly pretreatment coatings are poised to play an increasingly critical role in the coating landscape. Their evolution aligns with the broader shift towards responsible manufacturing practices, setting a new standard for the coatings industry—one that prioritizes both performance and the planet.

About Us

Stratview Research is a global market research firm, offering syndicated and custom research reports along with growth consulting services. Our business intelligence and industry research reports offer clients insightful market data to aid strategic decision-making. These exclusive reports are the result of exclusive research methodology and are available for key industries such as chemicals, composites, advanced materials, technology, renewable energy, and more.

Stratview Research delivers custom research services across sectors. In case of any custom research requirements, please send your inquiry to sales@stratviewresearch.com. Or connect with our experts at +1-313-307-4176.