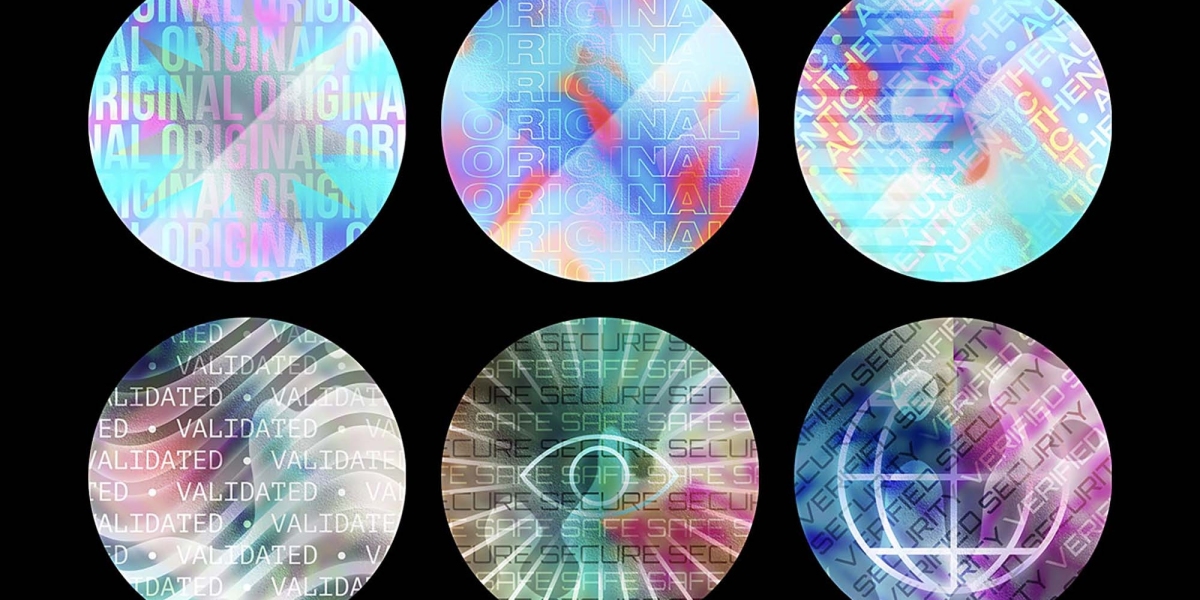

These shimmering, multidimensional labels have come a long way from their early days as anti-counterfeiting tools. Today, they serve a multitude of purposes, from protecting valuable products to adding a touch of elegance to branding and packaging. In this article, we'll explore the world of hologram sticker printing, its history, applications, and the technological marvels that make it possible.

The Origins of Hologram Sticker Printing

Before delving into hologram sticker printing, it's essential to understand the roots of holography. Holography is a photographic technique that records light patterns scattered off an object and then presents them in a three-dimensional form. Hungarian-British physicist Dennis Gabor introduced the concept of holography in 1947, though it took several decades for the technology to become practical.

In the early stages, holography was primarily a scientific curiosity. However, its potential for security applications quickly became apparent, leading to the development of hologram sticker printing.

Hologram Stickers as Security Features

Hologram stickers first gained recognition for their role in enhancing security measures. They offer several advantages over traditional security features:

Anti-counterfeiting: Hologram stickers are incredibly difficult to replicate accurately, making them an effective deterrent against counterfeit products and documents. The intricate patterns and 3D effects are challenging to reproduce with conventional printing methods.

Authentication: Holograms serve as an immediate visual means of authentication. Consumers and officials can quickly verify the authenticity of a product or document by checking for the presence of a genuine hologram.

Tamper Evidence: Many hologram stickers include tamper-evident features. If an attempt is made to remove or alter the hologram, it may break or leave visible evidence of tampering.

Customization: Hologram stickers can be customized with unique designs, text, and patterns, adding an extra layer of security. This customization makes it even more challenging for counterfeiters to replicate.

Applications Beyond Security

While hologram sticker printing remains a cornerstone of anti-counterfeiting measures, its applications have expanded far beyond security. Here are some areas where hologram stickers are making a significant impact:

Product Packaging: Hologram stickers add a touch of elegance and luxury to product packaging. They can enhance the visual appeal of cosmetics, electronics, and high-end consumer goods.

Branding and Marketing: Many brands use hologram stickers to create memorable and eye-catching logos, labels, and promotional materials. The holographic effect adds a sense of sophistication and innovation.

Collectibles and Memorabilia: Hologram stickers are often used on collectible items, including trading cards, limited-edition prints, and event tickets. Their uniqueness and aesthetic appeal make them highly desirable among collectors.

Document Authentication: Government agencies and institutions use holograms on identity cards, passports, and official documents to prevent forgery and enhance security.

The Technology Behind Hologram Sticker Printing

The production of hologram stickers involves a complex and precise process that combines optics, laser technology, and high-resolution printing. Here's a simplified overview of how hologram stickers are created:

Master Hologram: The process begins with the creation of a master hologram, typically using laser light. This master hologram contains the intricate interference patterns required to produce the holographic effect.

Replication: Multiple copies of the master hologram are created through a process called embossing or recombination. This involves transferring the holographic pattern onto a thin, flexible material, such as polyester.

Printing: The holographic material is then printed with additional design elements, such as text or graphics, using traditional printing methods like flexography or digital printing.

Coating and Adhesive: A protective coating is applied to the holographic material, ensuring its durability and resistance to wear and tear. An adhesive backing is also added to allow easy application to various surfaces.

Die-Cutting: The hologram stickers are die-cut into the desired shape and size.

Application: The hologram stickers are ready to be applied to products, packaging, or documents.

The Future of Hologram Sticker Printing

As technology continues to advance, hologram sticker printing is poised for further innovation. Some potential developments on the horizon include:

Advanced Security Features: Holograms are likely to incorporate even more sophisticated security features, making them virtually impossible to counterfeit.

Integration with Digital Platforms: Holograms could be integrated with digital authentication systems, allowing consumers to verify products through smartphone apps or websites.

Sustainable Materials: The industry is likely to explore more sustainable materials for hologram sticker production, aligning with growing environmental concerns.

In conclusion, custom hologram stickers uk has come a long way since its inception as a security measure. It has evolved into a versatile and creative tool with applications spanning security, branding, marketing, and aesthetics. As technology continues to advance, hologram stickers will remain a captivating blend of science and artistry, enhancing both the security and visual appeal of a wide range of products and documents.