Hybrid additive manufacturing (HAM) is a rapidly growing technology that combines two or more additive manufacturing (AM) processes to create parts with enhanced properties. This can be done by combining processes that use different materials, such as metal and plastic, or by combining processes that have different strengths and weaknesses, such as laser sintering and selective laser melting.

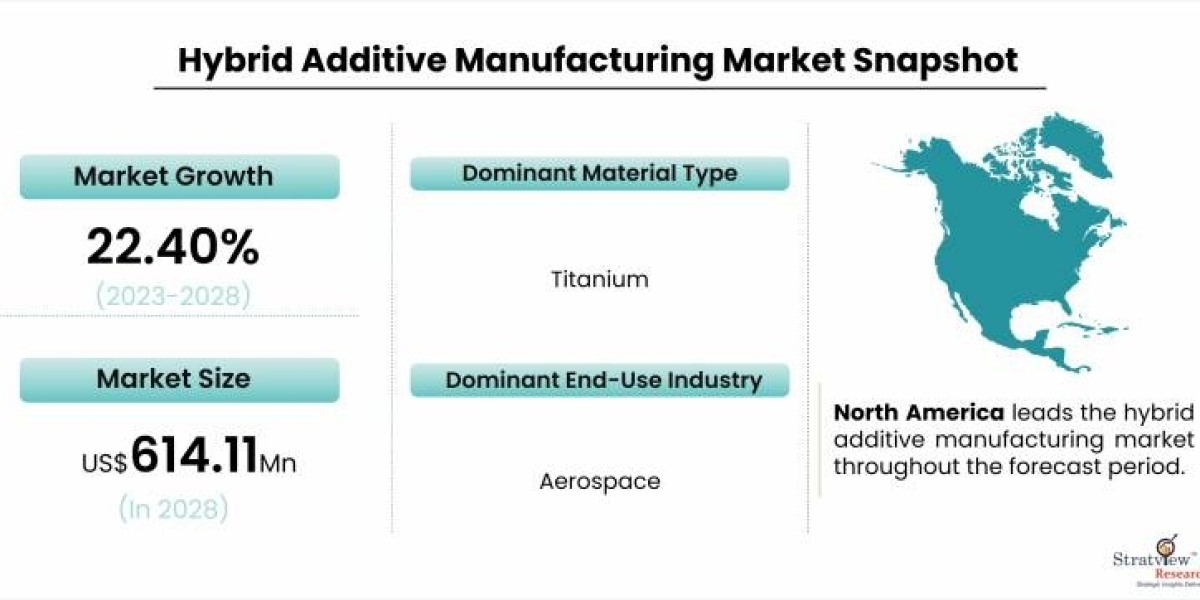

The global hybrid additive manufacturing market is expected to grow from USD 223.53 million in 2023 to USD 614.11 million by 2028, at a CAGR of 22.40%. The growth of this market is being driven by the increasing adoption of AM in a variety of industries, such as aerospace, automotive, medical, and dental.

One of the key drivers of the growth of the HAM market is the need for parts with enhanced properties. AM can be used to create parts with complex geometries and high strength-to-weight ratios. This makes it ideal for applications where weight and performance are critical, such as in the aerospace and automotive industries.

Another driver of the growth of the HAM market is the need for shorter production lead times. AM can be used to rapidly prototype and manufacture parts, which can help to reduce the time to market for new products.

The HAM market is segmented by type, application, and region. By type, the market is segmented into laser-based, electron beam-based and other. The laser-based segment is the largest segment, accounting for the majority of the market share. This is due to the widespread availability of laser-based AM systems and the high quality of parts that can be produced with this technology.

By application, the market is segmented into aerospace, automotive, medical, and dental. The aerospace segment is the largest segment, accounting for the majority of the market share. This is due to the need for lightweight and high-performance parts in aircraft and spacecraft.

By region, the market is segmented into North America, Europe, Asia Pacific, and Rest of the World. North America is the largest market for HAM, followed by Europe and Asia Pacific. This is due to the presence of major players in these regions and the high demand for AM parts from the aerospace, automotive, and medical industries.

The HAM market is facing some challenges, such as the high cost of equipment and the lack of skilled operators. However, the market is expected to grow at a significant rate in the coming years, as the advantages of HAM become more widely known and the technology becomes more affordable.

Here are some of the key trends that are expected to drive the growth of the hybrid additive manufacturing market in the coming years:

· The increasing adoption of AM in the aerospace, automotive, medical, and dental industries

· The development of new materials and processes for AM

· The growing demand for shorter production lead times

· The increasing focus on sustainability and the use of AM to reduce waste

The hybrid additive manufacturing market is a rapidly growing and evolving market. The market is expected to continue to grow at a significant rate in the coming years, as the technology becomes more affordable and the advantages of HAM become more widely known.