The types of CNC routers depend on their applications and axes features. One of the most common types is based on application features, including types of hobby CNC kits (mini types, small types, portable types, desktop types, benchtop types, tabletop types), and types of large industrial CNC kits (CNC wood routers, CNC metal routers, CNC stone routers, CNC foam routers, CNC plastic routers, CNC aluminum routers, CNC glass routers). The other is based on axis features, including 3 axis types, 4th axis (rotary axis) types, 4 axis types, 5 axis types, and multi axis types.

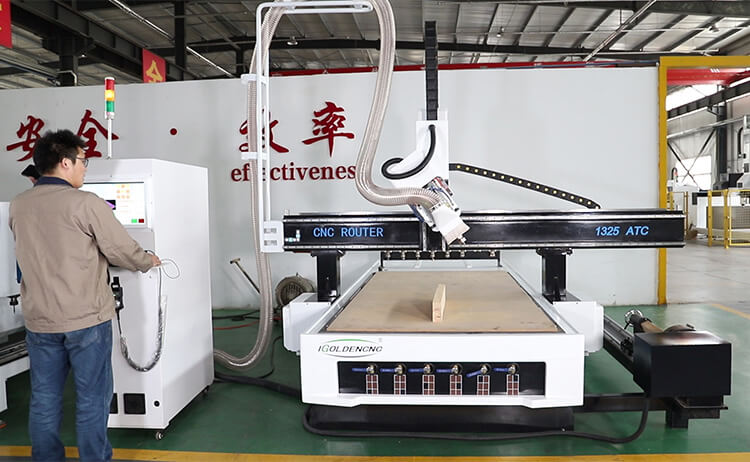

ATC CNC router is a type of CNC machining center with automatic tool changer kit that changes router bits in the tool magazine automatically instead of manual operation based on different designs for cabinet making, door making, furniture making, crafts making, decorations, musical instruments, sign making, windows, tables, and most popular woodworking projects & plans. The spindles usually carry tool magazines with 4, 6, 8,10, or 12 router bits and cutters. The tools can automatically change according to the working requirements when the machine works, no need of manual operation. You will meet three most common types of ATC CNC router kits, which include linear ATC CNC kits, drum ATC CNC kits (rotary ATC CNC kits), and chain ATC CNC kits.

A CNC router is a computer-controlled cutting machine used for various applications in woodworking, such as cutting, carving, and shaping wood. CNC routers are widely used in the woodworking industry due to their speed, precision, and ability to produce complex shapes and designs.

When it comes to choosing a CNC router for woodworking, there are several factors to consider, such as the size of the machine, the type of spindle, the cutting area, and the software used to control the machine.

There are many different types of CNC routers available for woodworking, each with its own strengths and weaknesses. Here are some of the most common types of CNC routers used in woodworking:

3-axis routers: These are the most common type of CNC router used in woodworking. They can move the cutting tool along the X, Y, and Z axes, allowing for the creation of a wide range of shapes and designs.

4-axis routers: These machines can move the cutting tool along the X, Y, and Z axes, as well as rotate the workpiece around a fourth axis. This allows for the creation of more complex shapes and designs.

5-axis routers: These machines can move the cutting tool along the X, Y, and Z axes, as well as rotate the workpiece around two additional axes. This enables the creation of even more complex shapes and designs, including curved and contoured surfaces.

CNC routers with automatic tool changers: These machines are equipped with a tool changer that allows them to automatically swap out cutting tools during the machining process. This can save time and increase efficiency, especially when working with complex designs that require multiple tools.

Desktop CNC routers: These machines are smaller and more affordable than their industrial counterparts, making them a good choice for hobbyists and small woodworking shops. They are ideal for cutting and carving smaller pieces of wood, such as signs, plaques, and decorative objects.

Here are some key considerations:

When choosing a CNC router for woodworking ,it’s important to consider the specific needs of your cnc woodworking projects . For example, if you plan to work with larger pieces of wood, a machine with a larger cutting area may be necessary. Similarly, if you plan to work with exotic hardwoods or other materials that require more power, a machine with a more powerful spindle may be necessary.

Size: 4×8 Wood CNC Router Machine

CNC routers come in different sizes, ranging from small desktop models to large industrial machines. The size of the machine you need will depend on the size of the projects you plan to work on. A larger machine can handle bigger projects, but it will also require more space and be more expensive.1325 Wood Working CNC Router Machine