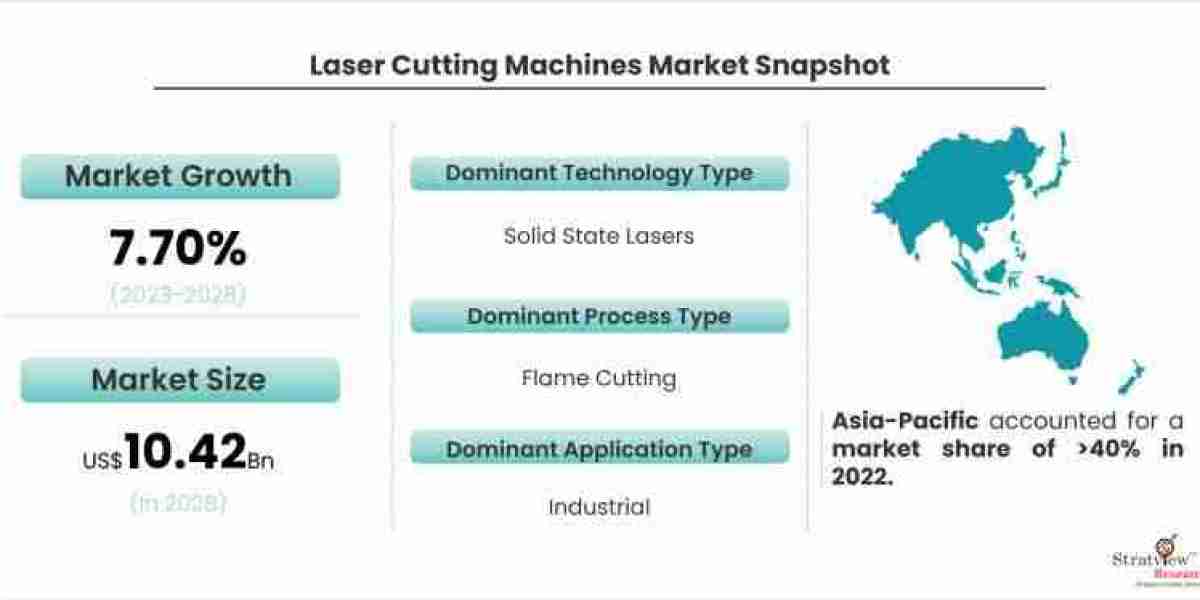

Laser cutting machines have become an integral part of the manufacturing and fabrication industry, enabling precise and efficient cutting of various materials. As technology continues to advance at a rapid pace, the future of laser cutting machines holds exciting prospects. In this blog, we will explore some of the key trends and forecasts that are shaping the future of laser cutting machines.

Advancements in Laser Technology:

Laser technology is continually evolving, and future laser cutting machines are expected to benefit from significant advancements. One key trend is the development of higher-powered lasers that can cut through thicker and tougher materials with ease. This will expand the application range of laser cutting machines, allowing them to tackle more challenging projects.

Integration of Automation and Robotics:

Automation and robotics are revolutionizing the manufacturing industry, and laser cutting machines are no exception. In the future, we can expect to see increased integration of automation and robotics into laser cutting systems. This will enable enhanced precision, speed, and efficiency by eliminating the need for manual intervention and streamlining the entire cutting process.

Improved Cutting Speeds:

As technology progresses, laser cutting machines will continue to improve their cutting speeds. Higher-powered lasers, optimized beam paths, and advanced control systems will contribute to faster cutting rates. This will not only increase productivity but also reduce production time and costs, making laser cutting machines even more attractive to manufacturers.

Enhanced Software and Connectivity:

Software plays a crucial role in operating laser cutting machines, and future advancements in this area will bring significant benefits. Advanced software solutions will provide improved design capabilities, real-time monitoring of cutting processes, and predictive maintenance features. Moreover, laser cutting machines will be increasingly connected to networks and integrated into the broader manufacturing ecosystem, enabling seamless data exchange and improved workflow management.

Integration of Additive Manufacturing:

Additive manufacturing, also known as 3D printing, has gained immense popularity in recent years. The integration of laser cutting machines with additive manufacturing technologies is an exciting trend for the future. This combination will allow for the creation of complex structures and the ability to cut and shape 3D printed components with precision. It opens up new possibilities for rapid prototyping and customized manufacturing.

Focus on Sustainability:

Sustainability is a growing concern in the manufacturing industry, and laser cutting machines are poised to contribute to a greener future. Future machines will focus on optimizing material usage, minimizing waste, and reducing energy consumption. Additionally, advancements in laser technology may lead to the adoption of cleaner and more energy-efficient laser sources, further reducing the environmental impact of the cutting process.

Expansion into New Industries:

While laser cutting machines are already widely used in industries such as automotive, aerospace, and electronics, the future will witness their expansion into new sectors. Industries like healthcare, renewable energy, and architecture are expected to increasingly adopt laser cutting technology to meet their specific needs. This expansion will drive further innovation and customization of laser cutting machines.

In conclusion, the future of laser cutting machines looks promising. Advancements in laser technology, automation, software, and connectivity will enhance their capabilities and efficiency. The integration of additive manufacturing and a greater focus on sustainability will further broaden their application range. As manufacturers continue to demand higher precision, faster speeds, and increased versatility, laser cutting machines will play a vital role in shaping the future of manufacturing and fabrication.