Laser Cleaning Machine

Laser rust removal/cleaning machine achieves the cleaning effect through high-energy laser, and laser rust removal is a non-contact processing method, so there is almost no damage to the substrate. There is no need for consumables such as chemical detergents, dry ice, cleaning jets, etc. in the process of rust removal or cleaning. In addition to no pollution to the global environment, it also saves the cost of consumables.

Laser cleaning uses a fiber laser that can last up to 100,000 hours, which allows us to make a return on our investment in a safe way. They are robust systems that are guaranteed to last for many years.

LASER CLEANER, LASER MACHINE

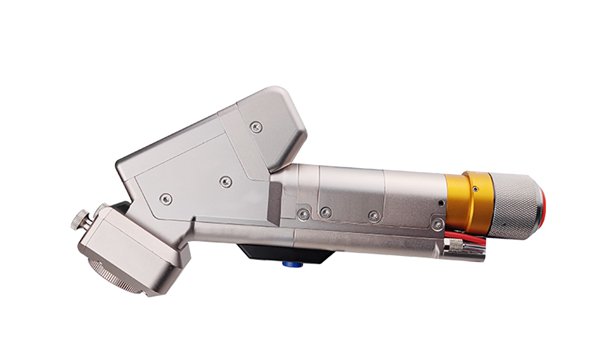

LASER CLEANER, LASER MACHINEHandheld Protable Laser Cleaning Machine for Rust Removal

Laser Remove Rust

Laser remove paint

Laser remove oil

Laser remove dust

Hand-held laser cleaning machine uses high-frequency and high-energy laser pulses to irradiate the surface of the workpiece, so that the surface oil, rust or coating evaporates or peels instantly, and effectively removes the surface attachment or surface coating of the cleaning object at a high speed, so as to achieve the cleaning of the object. crafting process. It is characterized by no damage to the part matrix, no consumables, energy saving and environmental protection.

laser cleaning machine for rust removal application include:

Derusting the metal surface; Surface paint removal treatment; Surface resin, oil stains, stains, and dirt cleaning; Surface plating and coating removal; Pretreatment of welding surface/spraying surface;

Removal of dust and attachments on the surface of the stone statue; Clean up the residue of rubber mold.

Mainly used in automobile manufacturing, mechanical processing, electronic processing, cultural relics restoration, mold industry, shipbuilding industry, food processing industry, petrochemical industry processing, petrochemical industry and other industries.