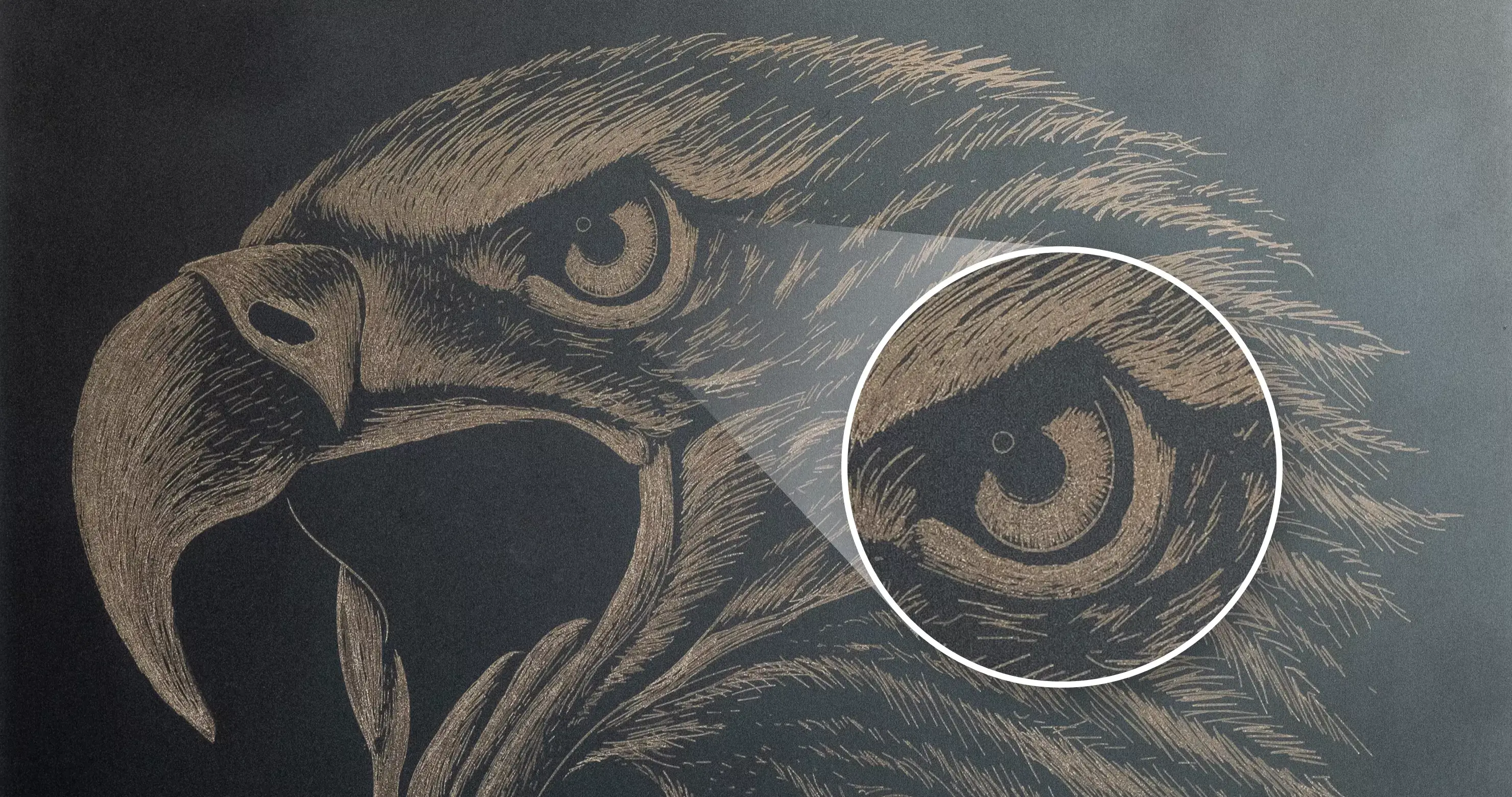

The technique of using laser engraving is an excellent way to personalize gifts or custom products. But for highly detailed or photo engraving, a consistent depth of focus is required. This is especially important when carving natural materials where the thickness of the material may fluctuate. Having an adjustable laser engraving bed or stage allows you to minimize any changes in the focus position on the workpiece.

Why not Just Use the Bed That Comes With the Laser Machine?

If you have a laser machine with an adjustable height bed, it will most likely be supported by 4 threads. On many laser machines manufactured, these threads are of poor quality and do not align precisely with each other. This can lead to a wobble effect.

While you can level the bed at a specific height, once you change height from that position, the wobble in the thread rotation can cause errors. So you may find that the bed is only really level with every full rotation of the adjusted position or thread. I actually made a thread alignment indicator that allows me to determine the full rotation position when I adjust the height of the bed.

Problems with The Provided Laser Bed.

Many of your laser machines will be equipped with honeycomb beds. These beds are not that level because they tend to sag in the middle due to the height difference between the honeycomb and support frame. This results in your engraved patterns not being as accurate. Of course, this depends on how the merchant packs it. For example, the xTool D1 Pro engraving machine I purchased is completely wrapped with foam. For this reason, the honeycomb panel inside the D1 Pro is still perfect when I receive it.

Another option offered by the laser machine is Lamella Bars. These are better for sheet work and can be difficult to level because the entire frame needs to be leveled before adding the sheet strips themselves.

Many cheaper machines will come with a simple thin aluminum bed, which can be subject to deformations such as bumps and dents during logistics. This makes the leveling of the workpiece more difficult, resulting in you not being able to properly level the engraving machine and the laser focus.

Provides a way to upgrade the aluminum bed provided by the laser engraver machine, with a piece of 3.0mm thick mild steel. It turns out that since there are no holes in the sheet, it is flatter, more stable and helps airflow through the workpiece. But I still need more precision for photo engraving.

Ideal Features for Adjustable Laser Engraving Beds

So how do we make an adjustable laser engraving bed? An adjustable bed needs to have a few characteristics to make it suitable for use as a laser engraving platform:

- The bed is completely flat. While you may be working with materials that are not perfectly flat, you will need a wider range of adjustments to keep the workpiece level with the laser head. The adjustment mechanism may also hinder the movement of the laser head.

- The material used needs to be stiff enough to support the workpiece without sagging.

- The material needs to be stiff enough to support the adjustment mechanism.

- The material in the adjustment area must not be bent.

- If threaded holes are used, the material needs to be strong enough not to peel off the holes.

- The bed should not be adversely affected by moisture or heat.

- Materials should not be adversely affected by accidental interaction with the laser beam.

- The materials used are not damaged by the laser

What Material Does My Laser Engraving Bed Use?

As mentioned, I ended up using a piece of 3.0mm thick mild steel left over from upgrading the laser machine. The sheet measures 410 x 400mm, which means it fits easily on my Ortur Laser Master 3 and allows me to use the full Y-axis range of 3900mm. The 4410mm X-axis range also allows for some overrun when engraving at high speeds.

What Other Materials Can I Use?

Acrylic sheet - this would have worked because it was really easy to tap on a 4mm acrylic sheet. Thickness on a sheet of paper can vary by +/- 0.5mm. If you have a sheet of extruded acrylic with tighter tolerances, you can use it with some nylon bolts.

Safety glass - You can find small pieces of tempered safety glass from an old refrigerator or other that have been in your warehouse all the time. Then design and fix some adjustment brackets, but it won't be too difficult. The main concern is the potential for impact damage, and the possibility that the laser/work area could fill up with broken glass.

Laser Engraving Bed Adjustment System

I chose to keep it simple and build on the design used by Russ Sadler. That said, there are only three manually adjustable M5 bolts with super glued wing nuts. Two bolts are located at the corners (15 mm inches) on the long side of the plate. And the remaining bolt is in the center of the other long side, again 15mm from the edge.

The mild steel plate is drilled with a 4.2mm drill bit, and the 3 holes are tapped with M5 threads. The heads of the bolts serve as the base for me to secure the steel bed.

Adjusting the Engraving Machine Itself is Simple:

- Make sure all adjusting bolts are approximately in the middle. This will give equal up and down adjustments.

- Place the adjustable laser engraving bed into the laser cavity and place it vertically in the center. With two bolts facing back edge.

- Add the product/item/sheet to be laser engraved, make sure it is within the working area of the laser machine, and take into account any overruns that may occur with high speed engraving.

- Place the laser nozzle on the top left corner of the item and raise/lower the entire bed until the nozzle is in the correct position. I used a piece of acrylic cut to the correct depth of focus as a gauge.

- Place the nozzle in the top right corner of the item and raise/lower the laser engraving bed by adjusting the right corner bolt until the acrylic gauge is snug. The bed is now horizontal from left to right.

- Move the laser nozzle to the bottom center of the item and adjust the bottom center bolt until the acrylic gauge is snug. The bed is now level fore and aft.

Safety Glass Laser Engraving Bed

The size of the safety glass should not exceed the engraving size of the engraving machine in millimeters, otherwise it will be too long to squeeze into the laser room. If you have some clear acrylic, you can also use it to make a stand.

Adjustable glass laser engraving bed Adjustable glass laser engraving bed

The stand measures 50 x 25mm with a 4.2mm hole. A smaller assembly is sandwiched between two larger assemblies, and a 4.3mm drill is used to align the parts. The parts are then glued together using WC123 PETG Weld Cement. Then tap each hole to M5. I realized a 12mm threaded hole would create too much friction, so I opened up each side of the faucet with a 5mm drill bit and added a little mineral oil.

Of course, another suggestion is that you can use a hand-held laser engraving machine, so that it will not be affected by this honeycomb panel, you can directly point the laser to the material you need to engrave, LaserPecker 2 is very good in this regard , almost will not result in inaccurate engraving.

To learn more about the engraving machine, you can go to the HTPOW online website for learning and consultation.

![Solderless Breadboards Market Size, Share, Growth, Trends [2032]](https://f002.backblazeb2.com/file/yoosocial/upload/photos/2024/05/gHjlOYYGJNdoCgq4mokB_29_d61ffa06c3ef7b8839cbebd79503f390_image.jpg)