TPU offers a vast combination of physical and chemical properties for the most demanding applications, such as breathable films for automotive, wire and cable, leisure, sports and textile coatings, weather resistance, non-yelding films, and more.

It has properties between plastic and rubber. Due to its thermoplastic nature, it has some advantages unmatched by other elastomers, such as:

Excellent tensile strength,

High elongation at break

Good carrying capacity

How is TPU produced?

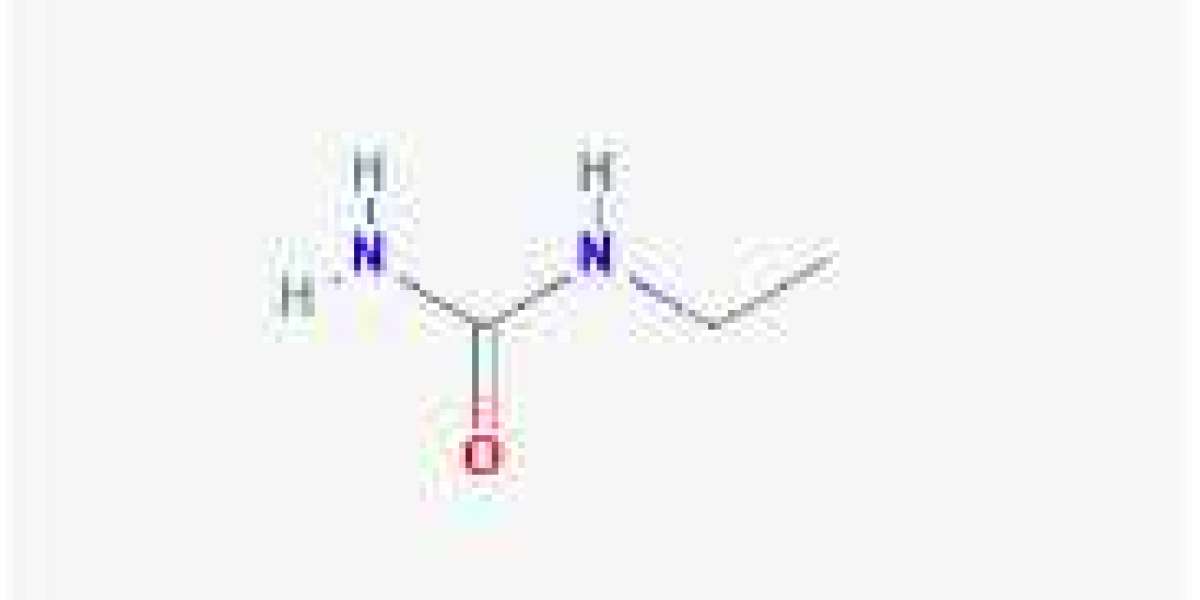

Diisocyanate is produced when a diisocyanate and one or more diols undergo a polymerization reaction in a specific manner. The three basic raw materials required for TPU production are:

Polyol or long chain diol

Chain extender or short chain diol

A diisocyanate

Other benefits of TPU

High elasticity over the entire hardness range

Excellent low temperature and impact strength

Elasticity to oils, oils and various solvents

Good flexibility over a wide temperature range

Strong resistance to weather and high energy radiation

Thermoplastic polyurethane has an elastic and fusible treatment. Additives can improve dimensional stability and heat resistance, reduce friction, increase flame retardant, fungal resistance and weather resistance.

Aromatic tpu is a strong, versatile resin that resists microbial attack and resists chemicals well. However, an aesthetic drawback is that aromatic hydrocarbons tend to be degraded by the free radical pathway upon exposure to high temperatures or ultraviolet light. This degradation results in discoloration and loss of physical properties.

It is a linear block copolymer consisting of hard and soft segments.