Industrial foam is a versatile material used across a wide range of applications in various industries, including automotive, construction, packaging, and healthcare. Known for its lightweight, durable, and insulating properties, industrial foam is produced in various forms, such as rigid, flexible, and spray foam. It is commonly made from materials like polyurethane, polystyrene, and polyethylene, offering customizable properties to suit specific needs. Its ability to absorb shock, insulate, and reduce noise makes it indispensable in both manufacturing processes and end-user products. As industries continue to demand higher performance materials, the use of industrial foam is expanding, particularly in innovative applications like energy-efficient building materials and advanced packaging solutions.

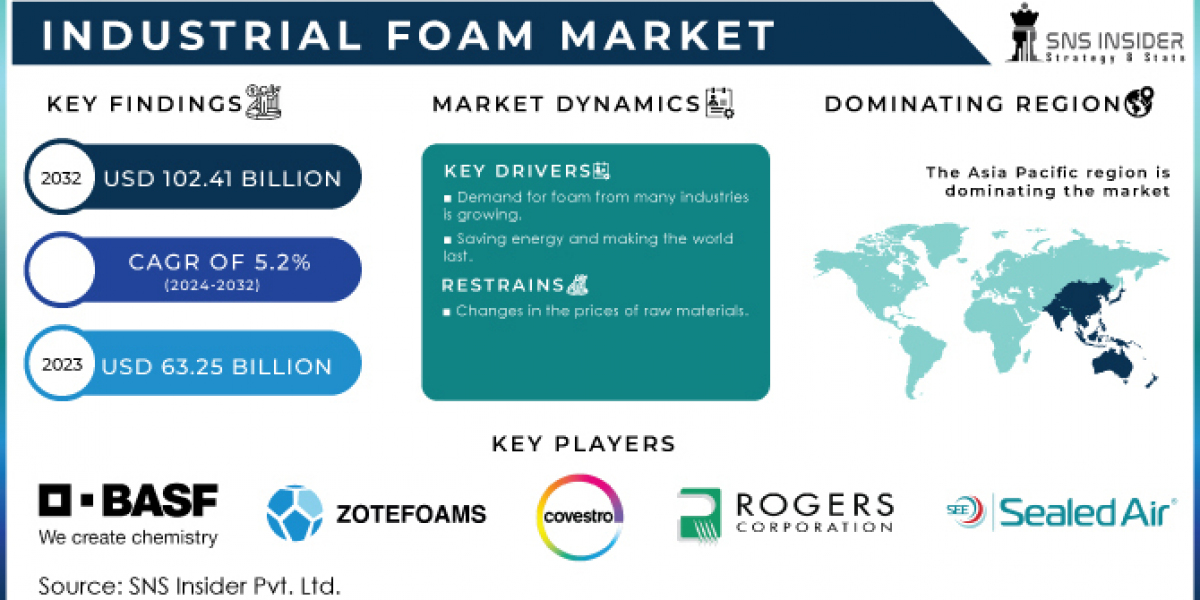

The Industrial Foam Market Size was valued at USD 63.25 billion in 2023 and is expected to reach USD 102.41 billion by 2032 and grow at a CAGR of 5.50% over the forecast period 2024-2032.

Future Scope

The future of industrial foam is focused on sustainability, with increasing research directed toward biodegradable and recyclable foams. The growing demand for environmentally friendly materials is pushing the development of plant-based foams and new technologies for recycling foam waste. Furthermore, advancements in smart foams—materials with the ability to adapt to external conditions like temperature, pressure, or moisture—are expected to open new opportunities in fields such as automotive, aerospace, and electronics. With the expanding focus on energy efficiency, industrial foams are likely to play a larger role in improving insulation and reducing energy consumption in buildings and vehicles.

Emerging Trends

Emerging trends in industrial foam include the use of bio-based and sustainable materials in foam production, reducing reliance on petrochemical sources. The automotive and construction industries are increasingly adopting advanced foam technologies for lightweighting, noise reduction, and insulation. The demand for high-performance foams in applications like thermal management, vibration damping, and protective packaging is on the rise. In the healthcare sector, foams are gaining attention for use in wound care, prosthetics, and cushioning materials. The use of 3D printing technologies to create customized foam structures is also a growing trend, particularly in the creation of complex, lightweight components for industries such as aerospace and robotics.

Drivers

The primary drivers of industrial foam growth include the rising need for lightweight materials in industries like automotive, aerospace, and construction, where fuel efficiency and sustainability are top priorities. Innovations in manufacturing processes, such as the ability to create foams with specific mechanical properties, are also driving market expansion. Increasing awareness of environmental concerns is pushing manufacturers to develop eco-friendly foams that can replace traditional materials. Additionally, the surge in e-commerce and demand for protective packaging solutions further contributes to the growth of the industrial foam market.

Restraints

Despite its numerous advantages, the industrial foam industry faces several challenges. One significant restraint is the environmental impact of certain types of foam, particularly those made from non-biodegradable materials like polystyrene. As concerns over plastic waste intensify, there is increasing pressure on manufacturers to adopt sustainable practices. The high cost of bio-based foams compared to conventional materials can also slow their widespread adoption. Moreover, the complexity of recycling foam and the lack of standardized recycling methods for different foam types limit the sustainability of foam materials.

Key Points

- Industrial foam is used in a wide range of industries, including automotive, construction, packaging, and healthcare.

- Future developments include the use of sustainable, biodegradable foams and innovations in smart foam technologies.

- Emerging trends highlight the adoption of bio-based materials, 3D printing, and advanced foam applications in insulation and noise reduction.

- Drivers include the growing demand for lightweight materials, eco-friendly alternatives, and protective packaging solutions.

- Restraints involve environmental concerns, high costs of sustainable foams, and recycling challenges.

Industrial foam continues to shape industries by offering cost-effective, efficient solutions for a variety of applications. As technological advancements push the boundaries of what foam can achieve, the material is set to become even more integral in the development of sustainable, high-performance products for diverse sectors.

Get Free Sample Copy @ https://www.snsinsider.com/sample-request/1906

Contact Us:

Akash Anand – Head of Business Development & Strategy

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)