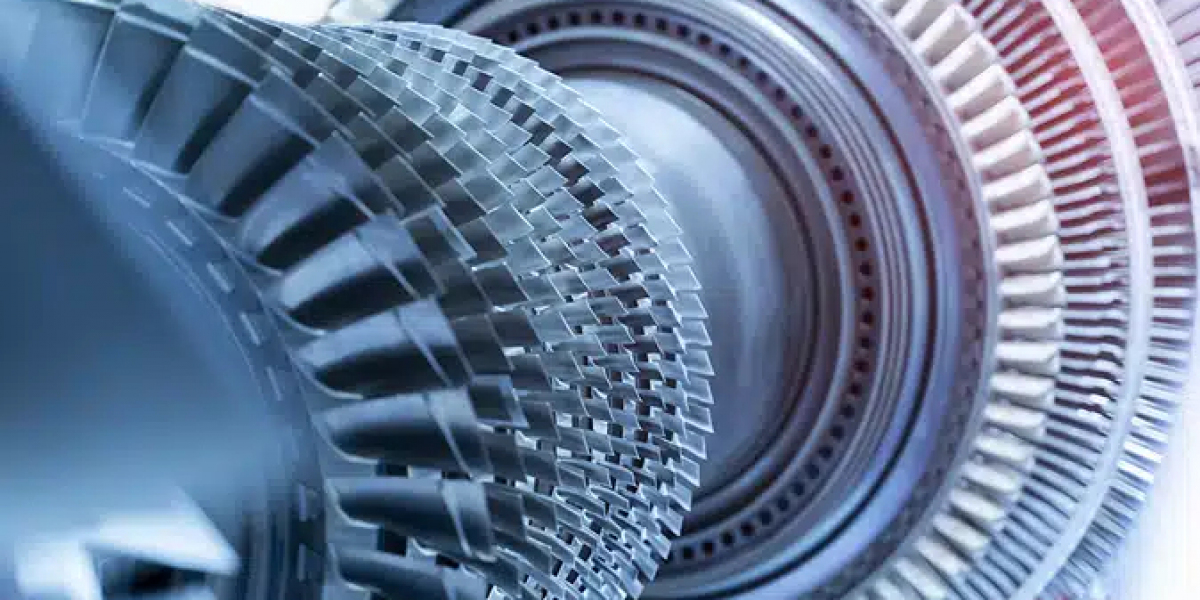

Aerospace manufacturing requires precision, efficiency, and consistency at every stage of production. Aerospace production tooling plays a crucial role in achieving these goals, ensuring that aircraft components meet strict safety and quality standards. Expert Technologies Group provides advanced aerospace tooling solutions that help manufacturers maintain their competitive edge. This article delves into the importance of aerospace production tooling and how Expert Technologies Group supports the industry with innovative solutions.

What is Aerospace Production Tooling?

Aerospace production tooling involves the use of specialised equipment, fixtures, and instruments to produce and assemble aircraft components with high precision. These tools ensure that every part fits correctly, operates efficiently, and meets stringent industry regulations.

Key types of aerospace tooling include:

- Moulds for Composites: Shape lightweight materials used in aircraft.

- Assembly Jigs and Fixtures: Secure components during manufacturing for accurate alignment.

- Specialised Drilling Tools: Ensure consistent placement of fasteners.

- Quality Inspection Tools: Verify compliance with engineering specifications.

The Role of Tooling in Aerospace Manufacturing

Tooling is integral to the production process, facilitating accuracy and efficiency at every step. With the right tools, aerospace manufacturers can:

- Achieve Precision: Tools ensure each part meets exact design specifications.

- Streamline Production: Automated systems speed up manufacturing processes.

- Maintain Quality Control: Inspection tools detect flaws early, minimising rework.

- Reduce Costs: Efficient production processes lower overall operational costs.

Aerospace Tooling Challenges and Solutions

Aerospace manufacturing presents several challenges, including:

- Complex Component Designs: Advanced tools are needed to handle intricate part geometries.

- Lightweight Material Use: Tooling must accommodate the rise in composite materials.

- Stringent Regulatory Requirements: Parts must meet safety and performance standards.

- Cost Constraints: Production tooling must balance quality with efficiency.

Expert Technologies Group offers tailored solutions to address these challenges, helping manufacturers optimise their production processes.

Expert Technologies Group: A Leader in Aerospace Production Tooling

Expert Technologies Group provides aerospace manufacturers with high-quality tooling solutions designed for precision, reliability, and efficiency. With a focus on innovation and customer collaboration, they create bespoke tooling systems that support demanding production environments.

Key Features of Their Tooling Solutions

- Customised Tool Design: Bespoke solutions tailored to each client’s manufacturing needs.

- Advanced Automation Integration: Robotics and smart technologies to streamline operations.

- Durability and Reliability: Tooling built to perform under demanding conditions.

- Global Service and Support: Worldwide delivery, installation, and maintenance.

Innovations in Aerospace Tooling Technologies

Expert Technologies Group stays ahead of industry trends by embracing the latest technologies in tooling:

1. 3D-Printed Tooling

Additive manufacturing allows rapid prototyping of tooling systems, reducing production lead times and costs.

2. Smart Tooling with Sensors

Sensor-enabled tools provide real-time data on performance and quality, helping manufacturers avoid production delays.

3. Robotic Automation

Robotic systems integrated with tooling improve accuracy and reduce the need for manual labour.

The Benefits of Choosing Expert Technologies Group

- Precision: Tools designed to meet the strict tolerances of aerospace manufacturing.

- Efficiency: Automation helps speed up production without compromising quality.

- Cost-Effectiveness: Reduced waste and faster processes save operational costs.

- Sustainability: Expert Technologies Group focuses on minimising waste and energy consumption.

Conclusion

In the fast-paced world of aerospace manufacturing, precision production tooling is essential for meeting industry demands. Expert Technologies Group offers advanced aerospace tooling solutions that empower manufacturers to enhance efficiency, maintain quality, and reduce costs. With a commitment to innovation and customer collaboration, their tooling systems meet the unique challenges of modern aerospace production.

If you are seeking high-performance aerospace production tooling, look no further than Expert Technologies Group. Their expertise and cutting-edge solutions are designed to help you optimise your production process and stay ahead in the competitive aerospace industry.