Defect detection is a critical aspect of quality assurance in various manufacturing and production processes. The ability to identify defects early in the production cycle not only enhances product quality but also reduces waste and minimizes costs. Advanced technologies for defect detection encompass a range of techniques, including visual inspection, ultrasonic testing, and machine learning algorithms. These methods are employed across industries, from automotive and aerospace to electronics and consumer goods, ensuring that products meet rigorous quality standards.

As manufacturing processes become more complex, the need for reliable defect detection systems has never been greater. The adoption of automation and advanced sensing technologies has transformed the landscape of quality control, enabling real-time monitoring and analysis. This shift towards intelligent defect detection systems is revolutionizing how manufacturers approach quality assurance, leading to more efficient and effective processes.

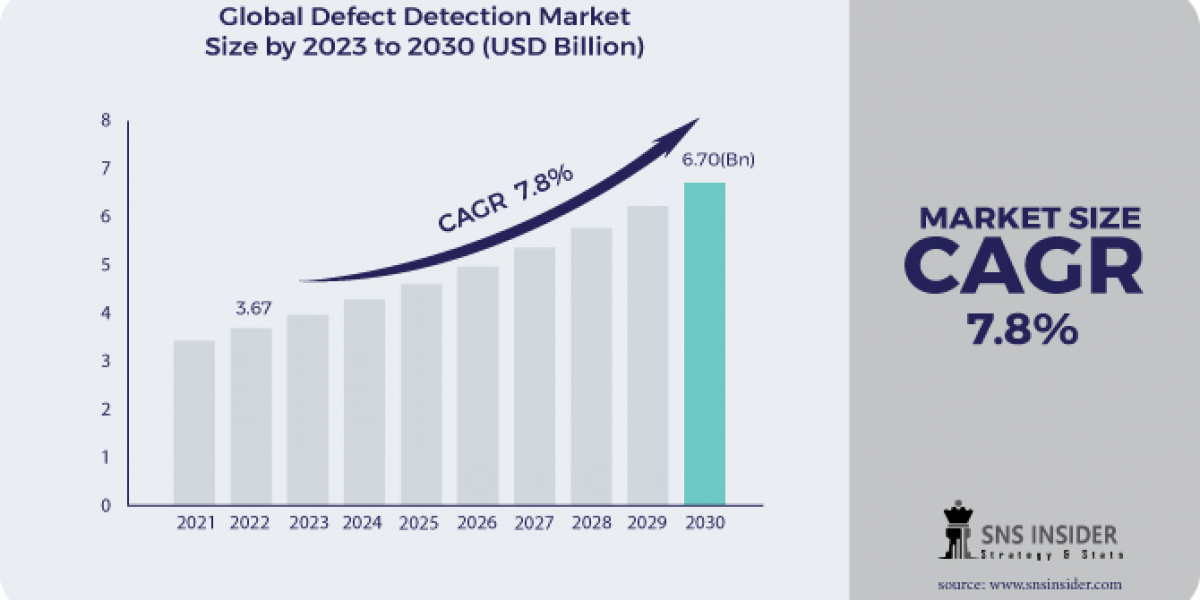

Defect Detection Market Size was valued at USD 3.67 billion in 2022 and is expected to reach USD 6.70 billion by 2030, and grow at a CAGR of 7.8% over the forecast period 2023-2030.

Future Scope

The future of defect detection technologies is promising, with substantial growth expected as industries increasingly prioritize quality and efficiency. As manufacturing processes continue to evolve, the demand for advanced defect detection solutions will expand. Technologies such as artificial intelligence (AI) and machine learning are set to play a pivotal role in this evolution, enabling systems to learn from historical data and improve detection accuracy over time.

Furthermore, the integration of IoT technologies will enhance defect detection capabilities by allowing real-time data collection and analysis. Connected devices can provide valuable insights into production processes, facilitating proactive measures to identify and address potential defects before they become significant issues. This trend towards predictive maintenance will ultimately lead to improved product quality and reduced operational costs.

Trends

Several key trends are shaping the defect detection market. One notable trend is the increasing adoption of automated inspection systems, which leverage advanced imaging technologies such as machine vision and infrared sensing. These systems enable rapid and accurate defect detection, significantly reducing the reliance on manual inspection processes. The efficiency and precision offered by automated systems are driving their widespread adoption across various industries.

Another trend is the growing emphasis on data-driven decision-making in defect detection. Manufacturers are increasingly utilizing data analytics to gain insights into production processes and identify patterns related to defects. This approach not only enhances detection capabilities but also allows for continuous improvement in quality control processes.

Application

Defect detection systems find applications across a wide range of industries. In the automotive sector, these systems are employed to ensure the quality of critical components such as engines, transmissions, and safety systems. Early detection of defects in these components is essential for maintaining safety and reliability.

In electronics manufacturing, defect detection plays a crucial role in ensuring the functionality and performance of electronic components and assemblies. Advanced inspection techniques are used to identify defects in printed circuit boards (PCBs), integrated circuits, and other electronic components, helping to maintain product quality and reliability.

Additionally, defect detection is vital in the consumer goods industry, where manufacturers must ensure that products meet consumer expectations for quality and performance. From food packaging to appliance manufacturing, effective defect detection systems are critical for delivering high-quality products to the market.

Key Points

- Critical for quality assurance in manufacturing and production processes.

- Advanced technologies enhance early defect identification, reducing waste and costs.

- Future growth driven by AI, machine learning, and IoT integration.

- Trends include automated inspection systems and data-driven decision-making.

- Applied across automotive, electronics, and consumer goods industries.

Read More Details: https://www.snsinsider.com/reports/defect-detection-market-2049

Contact Us:

Akash Anand — Head of Business Development & Strategy

Email: info@snsinsider.com

Phone: +1–415–230–0044 (US) | +91–7798602273 (IND)