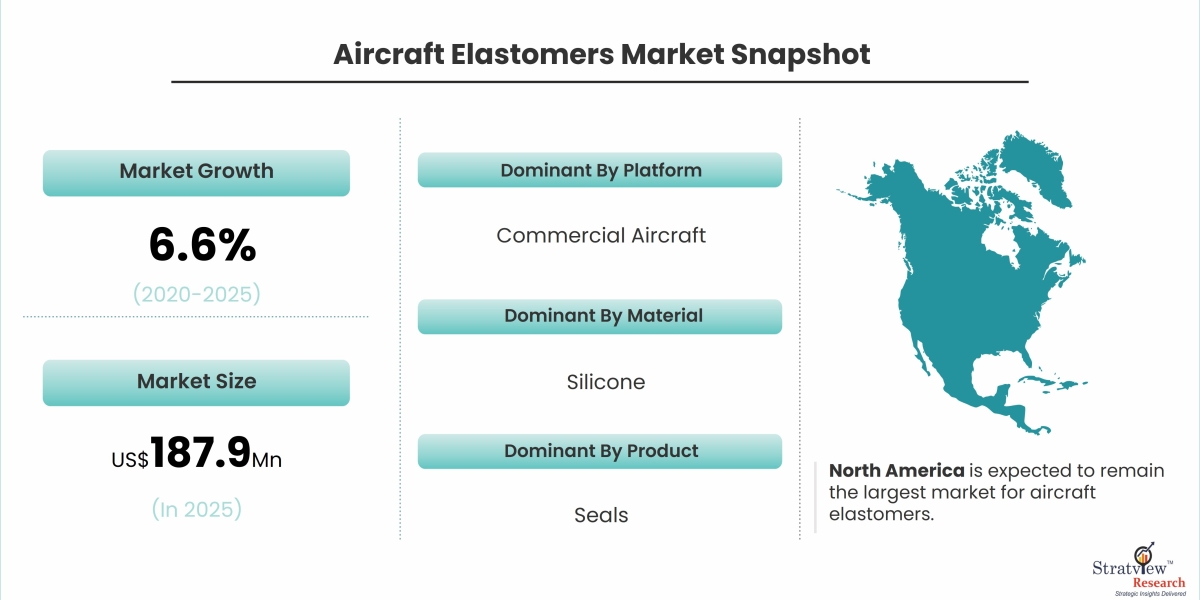

According to Stratview Research, the aircraft elastomers market was estimated at USD 172.2 million in 2019 and is likely to grow at a CAGR of 6.6% during 2020-2025 to reach a value of USD 187.9 million in 2025. Post taking a nose-dive in 2020 due to the pandemic, the demand for elastomers rose and is expected to grow steadily till 2025.

When we look up at the skies and marvel at the wonder of flight, we often focus on the high-tech aspects of aircraft, such as engines, avionics, and aerodynamics. However, behind the scenes, a less conspicuous hero plays a crucial role in ensuring aviation safety and comfort – aircraft elastomers. These specialized rubbery materials, with their unique properties, are the unsung heroes of the aviation world. In this article, we will explore the role of aircraft elastomers in aviation and their invaluable contributions to the industry.

Understanding Aircraft Elastomers

Aircraft elastomers, also known as elastomeric materials or rubber compounds, are a class of materials with a remarkable ability to deform under stress and return to their original shape when the stress is removed. This elastic property, combined with their resistance to environmental factors, makes them indispensable in aviation.

The Vital Functions of Aircraft Elastomers

Vibration Isolation: Aircraft operate in a dynamic environment, and they encounter various forms of vibration, whether from engine operation, turbulence, or landing. Elastomers are used to isolate critical components like engines, landing gear, and avionics from these vibrations. They prevent these components from shaking excessively and protect them from structural damage.

Shock Absorption: Elastomeric shock mounts are used in the landing gear system to absorb the tremendous forces generated during landings. They provide a cushioning effect, making landings smoother and more comfortable for passengers.

Sealing and Gasketing: Aircraft require airtight seals to prevent leakage of fluids, such as fuel and hydraulic fluids. Elastomeric seals and gaskets create a secure barrier against leaks, ensuring the safe and efficient operation of aircraft systems.

Damping: Elastomers are also used in damping applications to reduce noise, vibration, and harshness (NVH) levels in the cabin and flight deck, enhancing passenger comfort.

Key Applications of Aircraft Elastomers

Landing Gear: Landing gear shock mounts use elastomeric materials to absorb and dissipate the energy generated upon landing, protecting the aircraft's structure and passengers.

Engines: Engine mounts feature elastomeric elements that isolate engine vibrations, preventing their transmission to the airframe and improving passenger comfort.

Hydraulic Systems: Elastomeric seals are crucial in hydraulic systems to prevent fluid leakage. They ensure the proper functioning of critical components like hydraulic actuators.

Aircraft Interiors: In the cabin, elastomers are used in various components, including passenger seating, gaskets, window seals, and even tray table dampers, contributing to passenger comfort and safety.

Innovations in Aircraft Elastomers

The field of aircraft elastomers is not static. Innovations continue to shape this industry, with a focus on improving safety, durability, and efficiency. Some key developments include:

Advanced Materials: Ongoing research into novel elastomeric materials with enhanced resistance to extreme temperatures, chemicals, and wear.

3D Printing: Additive manufacturing technologies are used to create custom elastomeric components with intricate designs, improving efficiency and reducing waste.

Smart Elastomers: The development of smart elastomers capable of changing their properties in response to external conditions, offering enhanced adaptability and safety.

Sustainability: Increasing attention to sustainable elastomeric materials as the aviation industry seeks to reduce its environmental impact.

Conclusion

Aircraft elastomers, with their elastic properties, resistance to harsh environmental conditions, and ability to absorb shocks and vibrations, are indispensable in aviation. They are the unsung heroes behind the scenes, ensuring the safety, comfort, and efficiency of air travel. As innovation continues to shape the Aircraft Elastomers industry, we can expect even more advanced materials and solutions that enhance aviation safety and efficiency. Elastic skies are, indeed, a testament to the invaluable contributions of aircraft elastomers to the world of aviation.