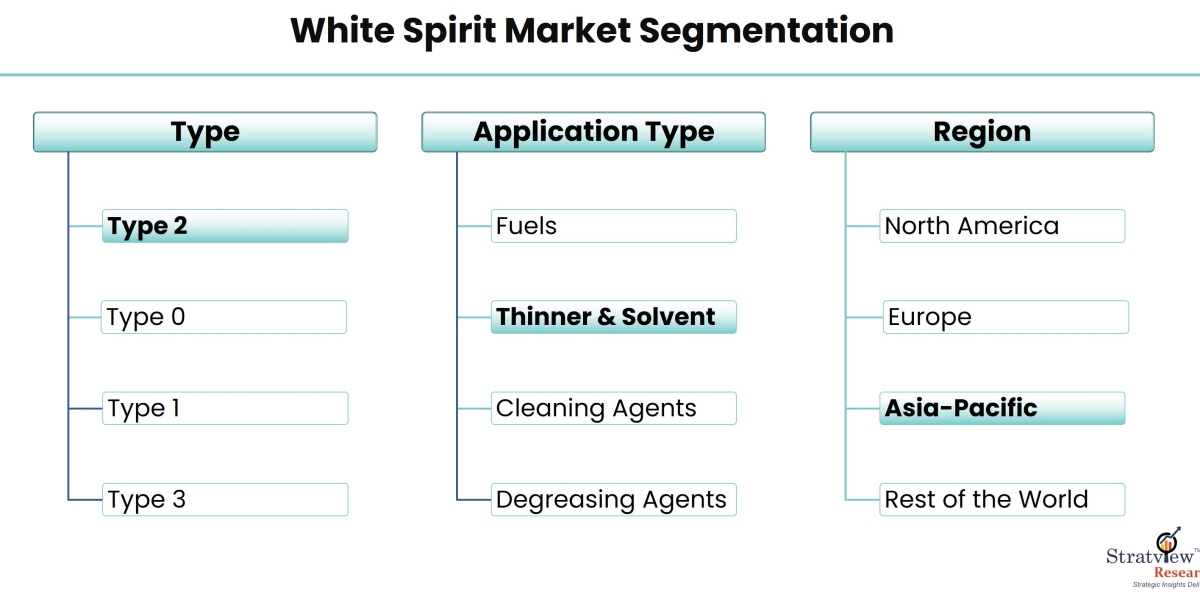

According to Stratview Research, the white spirit market is segmented by Type (Type 0, Type 1, Type 2, and Type 3), by Flash Point Type (Low, Medium, and High), by Application Type (Thinner & Solvent, Fuels, Cleaning Agent, Degreasing Agent, and Others), and by Region (North America, Europe, Asia-Pacific, and Rest of the World).

White spirit, also known as mineral spirits or mineral turpentine, has long been a stalwart in various industries, serving as a versatile solvent with a wide range of applications. From paint and coatings to cleaning and degreasing, this essential solvent has played a pivotal role in industrial processes for decades. However, in an era of rapid technological advancement and a growing focus on sustainability, the white spirit industry is not resting on its laurels. Instead, it is embracing innovation and advancing its technology to meet the evolving needs of the market. In this article, we will explore the latest innovations and advancements in white spirit technology.

1. Low-VOC Formulations

One of the most significant advancements in white spirit technology is the development of low-VOC (volatile organic compound) formulations. VOCs are compounds that can evaporate into the air and contribute to air pollution, smog formation, and respiratory issues. In response to tightening environmental regulations and growing consumer demand for eco-friendly products, manufacturers have been working to reduce the VOC content in white spirit products.

Low-VOC white spirits offer several advantages:

Reduced environmental impact: Lower VOC emissions contribute to improved air quality and reduced environmental harm.

Enhanced worker safety: Reduced exposure to harmful VOCs improves the safety and health of workers handling white spirit.

Compliance with regulations: Low-VOC formulations ensure compliance with stringent environmental standards.

2. Bio-Based White Spirits

In line with the global trend toward sustainability, bio-based white spirits have emerged as a promising innovation. These bio-based solvents are derived from renewable feedstocks such as agricultural crops or waste materials. Bio-based white spirits offer several advantages:

Reduced carbon footprint: Bio-based solvents typically have a lower carbon footprint compared to their petroleum-based counterparts.

Renewable resources: Utilizing renewable feedstocks reduces reliance on fossil fuels.

Enhanced sustainability: Bio-based white spirits align with sustainability goals and environmental stewardship.

3. Improved Safety Measures

Safety remains a top priority in the handling and use of white spirits. Advancements in technology have led to improved safety measures in the production, transportation, and use of white spirits. These include:

Enhanced safety labeling and packaging to communicate hazards and proper handling procedures.

Improved personal protective equipment for workers.

Automation and remote monitoring systems to reduce human exposure to white spirit vapors.

4. Sustainable Production Practices

In addition to the development of sustainable product formulations, white spirit manufacturers are increasingly adopting sustainable production practices. These include:

Energy-efficient manufacturing processes to reduce energy consumption and greenhouse gas emissions.

Waste reduction and recycling initiatives to minimize environmental impact.

Responsible sourcing of raw materials to ensure ethical and sustainable supply chains.

5. Digitalization and Data Analytics

The adoption of digital technologies and data analytics is transforming the white spirit industry. These technologies offer several benefits:

Real-time monitoring of production processes to ensure efficiency and quality control.

Predictive maintenance to reduce downtime and optimize equipment performance.

Supply chain optimization to improve logistics and reduce transportation-related emissions.

6. Customized Solutions

As industries become more specialized and consumer preferences continue to diversify, white spirit manufacturers are offering customized solutions to meet specific needs. Customized formulations and blends cater to industries with unique requirements, such as aerospace, electronics, and pharmaceuticals.

7. Green Packaging and Recycling

Innovations aren't limited to the white spirit itself; they also extend to packaging and recycling solutions. Manufacturers are exploring eco-friendly packaging materials and recycling programs to reduce the environmental impact of packaging.

Conclusion

Innovation and advancements in white spirit technology are driving the industry toward a more sustainable and environmentally responsible future. From low-VOC formulations to bio-based solvents, improved safety measures, sustainable production practices, and digitalization, the white spirit industry is adapting to meet the changing demands of a rapidly evolving world.

As environmental concerns and sustainability goals take center stage, white spirit manufacturers are at the forefront of addressing these challenges. By embracing innovation, they are not only meeting regulatory requirements but also providing solutions that align with the growing demand for eco-friendly products and practices. The future of white spirit technology is marked by sustainability, safety, and efficiency, ensuring that this indispensable solvent continues to play a vital role in various industries while minimizing its impact on the environment and human health.