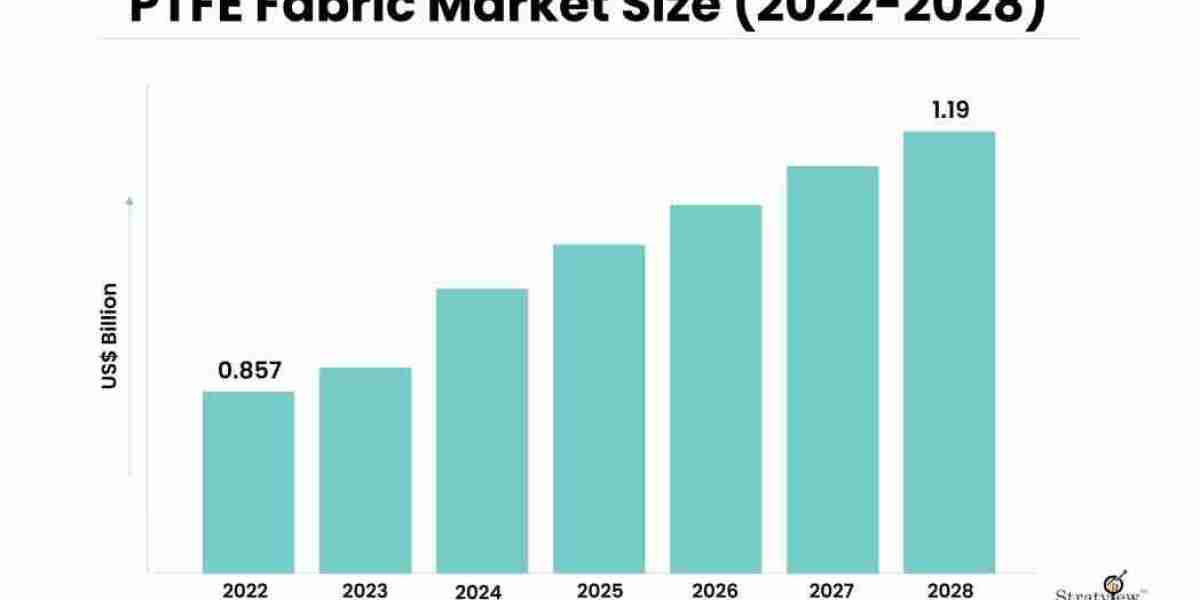

In the quest for a greener and more sustainable future, the importance of finding eco-friendly alternatives in various industries cannot be overstated. One such solution that has gained prominence in recent years is PTFE fabric, also known as Teflon. While PTFE fabric has long been associated with its non-stick properties in cookware, its environmental benefits extend far beyond the kitchen. This article delves into the environmental advantages of PTFE fabric and highlights its potential as a sustainable solution for a greener future. The PTFE fabric market is estimated to grow from USD 0.857 billion in 2022 to USD 1.19 billion by 2028 at a healthy CAGR of 5.50% during the forecast period.

PTFE fabric is derived from a synthetic polymer known as polytetrafluoroethylene. What sets PTFE fabric apart from conventional materials is its remarkable resistance to heat, chemicals, and weather conditions. This makes it highly durable and long-lasting, reducing the need for frequent replacements. By opting for PTFE fabric, industries can significantly reduce their environmental footprint, as fewer resources are consumed in the manufacturing and disposal processes.

One of the primary environmental benefits of PTFE fabric is its exceptional resistance to heat. This property makes it an ideal choice for applications that involves high temperatures, such as thermal insulation. PTFE fabric can effectively insulate equipment, reducing the need for excessive energy consumption. By minimizing heat loss, PTFE fabric helps to conserve energy and reduce greenhouse gas emissions.

Moreover, PTFE fabric's resistance to chemicals makes it an excellent alternative for industries that deal with corrosive substances. Unlike conventional materials, PTFE fabric does not react with most chemicals, demonstrates that it remains unaffected and maintains its integrity over time. This resistance translates into reduced material degradation and, subsequently, less waste generated. Industries utilizing PTFE fabric can enjoy longer-lasting equipment and minimize their environmental impact through reduced waste production.

In addition, PTFE fabric exhibits exceptional weather resistance. It can withstand extreme weather conditions, including high humidity, temperature fluctuations, and UV exposure. This property makes PTFE fabric an excellent choice for outdoor applications, such as architectural membranes and roofing materials. By choosing PTFE fabric for these purposes, industries can minimize maintenance requirements and extend the lifespan of structures. Consequently, this reduces the consumption of raw materials and lowers the overall environmental impact.

Furthermore, PTFE fabric is inherently non-stick, which has made it popular in the kitchen. However, this characteristic also has important environmental implications. In cookware applications, PTFE fabric's non-stick property allows for reduced oil and grease usage during cooking. As a result, less waste is generated, and water resources required for cleaning are minimized. By encouraging more sustainable cooking practices, PTFE fabric contributes to a greener and more resource-efficient lifestyle.

Another notable environmental advantage of PTFE fabric is its recyclability. PTFE fabric can be recycled and processed into new products, reducing the demand for virgin materials. This aspect enjoys the circular economy model and supports sustainable resource management. By opting for PTFE fabric and participating in recycling programs, industries can contribute to the reduction of waste and the conservation of resources.

In conclusion, PTFE fabric offers numerous environmental benefits that make it a sustainable solution for a greener future. Its exceptional heat resistance, chemical resistance, weather resistance, non-stick properties, and recyclability all contribute to reducing environmental impacts in various industries. By choosing PTFE fabric over conventional materials, companies can minimize waste generation, conserve resources, and lower energy consumption. Embracing PTFE fabric as a sustainable alternative paves the way for a more eco-friendly future across different sectors, from architecture to cooking. With its versatile applications and environmental advantages, PTFE fabric emerges as a promising solution in the journey towards a greener and more sustainable world.