ATC stands for Automatic Tool Change, which means that the machine can change cutting tools automatically based on the requirements of the design being cut.The ATC Woodworking CNC Router Machine is typically equipped with a spindle motor, a cutting table, a control panel, and various cutting tools. The spindle motor is the power source that drives the cutting tool and can be adjusted to control the speed and torque of the cutting process. The cutting table provides a stable platform for the material being cut and can be adjusted to accommodate different sizes and shapes of workpieces.

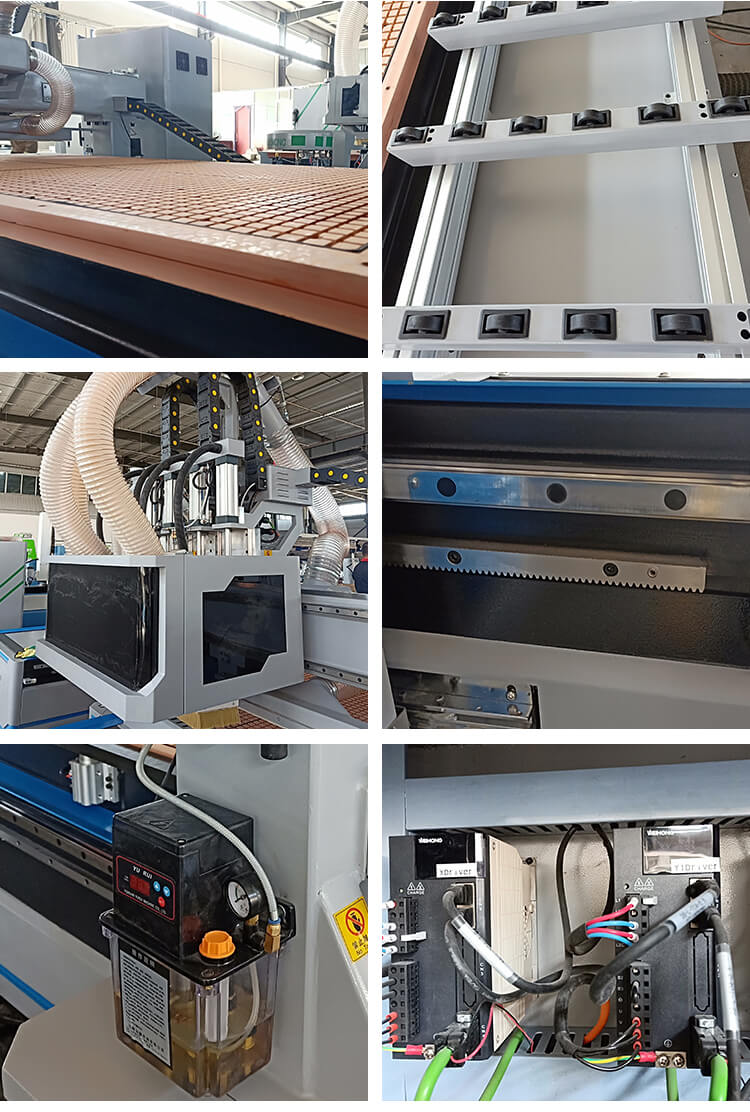

Best ATC CNC Router Wood Details

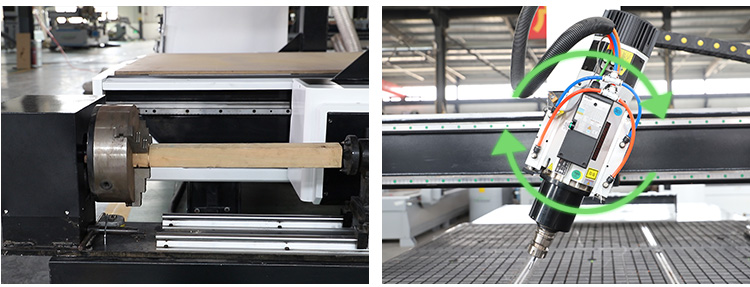

Tool changer magazine + 9KW air-cooled spindle

Rotary device + Swing head

How does a ATC CNC Wood Router Help a Manufacturer?

1. Improved Production Range

Industrial ATC CNC wood routers have revolutionized the woodworking industry. This computer-controlled machine rarely produces any waste pieces and operates at high-efficiency. This machine can substantially increase the range of production of woodworking firms without requiring it to hire a qualified technician for the machine.

2. Larger Cutting Field

Be it large pieces like stair risers or small 3d carving, a CNC Router for Wood Carving is capable of producing designs that are a challenge for a standard wood router that too at a higher speed. In the case of mass production, a woodworking firm can opt for bigger CNC wood router that have a low margin of error and produce large pieces of wood at ease.

3. Ease of Operation

Standard routing requires a woodworker to physically manipulate the wood router. This method is not advisable as it severely impacts the quality of the product and safety of the woodworker. Besides, the working of these hand routers is something that cannot be taken for granted, hence, it requires an operator with significant experience along with the training of the router.

Whereas, a CNC wood router does not require a skilled operator. It only requires a woodworker to have computer training in coding, which is could be gained in a matter of a few months.

4. Less Waste, Less Dangerous

This is a common issue among the woodworkers using standard wood routers. Their investment is significantly higher than their compatriots who are using CNC Routers for Wood. The reason being, the loss of money is directly related to the loss of material on the work floor. So, more the waste, the cost incurred is also more. Lacking in accuracy, hand routers tend to provider results on the expensive side of the spectrum. Furthermore, the chances of woodworker making a serious error are also high.

5. Flawlessly Accurate

As mentioned above, the best part about the CNC wood router is that it is accurate. Since it is a computer-controlled machine, the CNC router possesses the capacity of producing thousands and hundreds of finished products that too at the same time! For firms and woodworkers who value time, accuracy, and high-quality, this machine is the insurance for making your work invaluable.

CNC Wood Router Maintenance

Proper maintenance and operation in the right way can extend your CNC wood machine’s life and reduce the incidence of failures.

Avoid direct sunlight, excessive humidity, and dust

Keep your wood CNC machine away from any equipment with high vibration

Keep dust away from wood CNC router machine wheels and bearings

Use CNC wood carving machine according to manufacturer’s wood CNC machine instructions

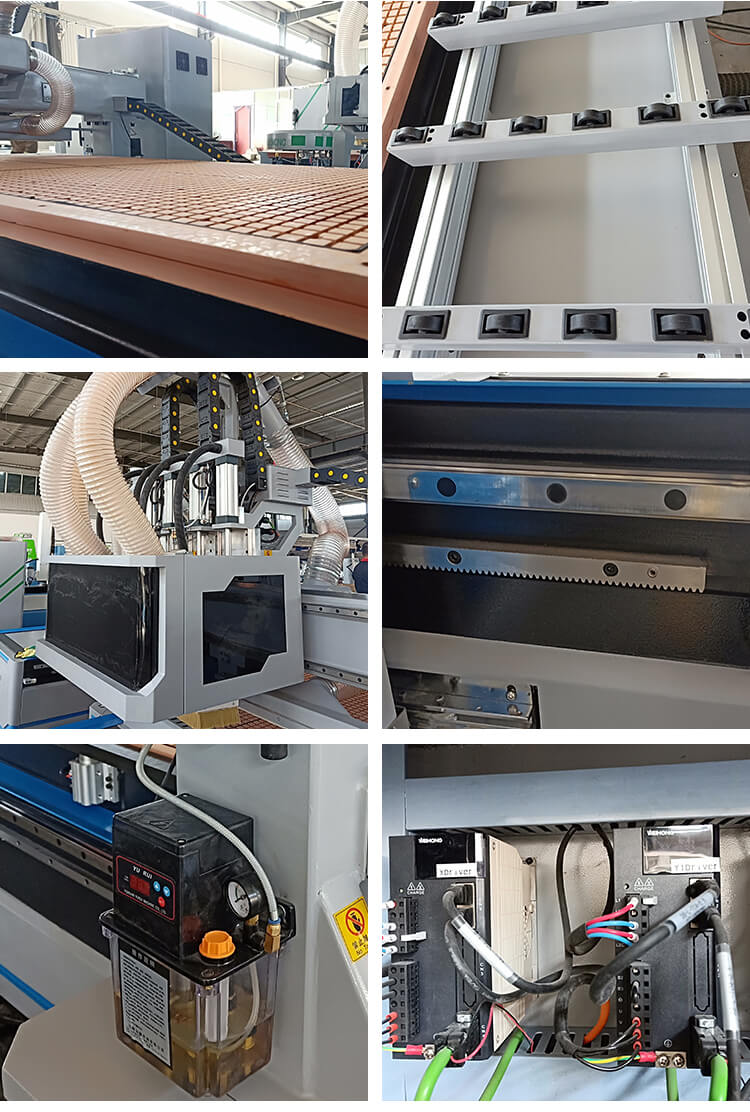

New style best 8 tools atc woodworking cnc router, fulfilling the need for the production with most wooden materials. With 8 or 12 sets of linear tools to change automatically, which can saving time of tools changing and improving working efficiency. Multi tools for choice, meeting all kinds of engraving and cutting needs. It is widely use in wooden furniture manufacturing. What is the features of atc cnc router machine? Please follow us:

Why To Choose The Best 8 Tools ATC Woodworking CNC Router?

First, high productivity. Equipped with automatic tool changing device, which can meet the tool changing requirements during processing without manual participation. With simple and easy operation mode to learn, which can help users quickly grasp the use of methods and greatly improve production efficiency.

Second, imported spare parts.

Adopting the automatic tool changing spindle, it has the advantages of good starting performance, fast processing speed, large torque and high processing efficiency.

Adopting Italy HSD spindle motor, and spindle bearings with high-precision ceramic bearings, it has the advantages of low noise and long service life.

Equipped with the imported high torque servo motor, it has the advantages of low noise, fast speed and high positioning accuracy.

Equipped with a unique tool changing device and a dedicated tool setting table, it can realize automatic tool changing without intermittent with fast tool changing speed, and can accurately compensate for tool length errors.

Adopting Taiwan linear guide and ball screw, it has the advantages of high bearing capacity and accurate cutting.

Third, good software compatibility. Adopting open software interface, it can be compatible with the processing codes generated by various CAD / CAM design software, such as type3 / Artcam / JDpaint / Wentai, to ensure the realization of various design functions.

Best 8 Tools ATC Woodworking CNC Router Parameters:

Applicable Industries Of Best 8 Tools ATC Woodworking CNC Router:

Woodworking industry: Solid wood furniture, solid wood art murals, MDF paint-free doors, composite doors, cabinet windows, bedside tables, screen carvings, mahogany furniture, wave board processing and other furniture.

Advertising industry: Acrylic, two-color plate, PVC, ABS, aluminum-plastic plate engraving, various signs, advertising signage, sign making, cutting of advertising materials, blister molding, LED neon making and other advertising decoration products.

Soft Metal Industry: Can engraving various metal molds: steel, copper, aluminum and other soft metals.

Best 4×8 Wood CNC Router Machine for Sale

CNC Machining Center

ATC CNC ROUTER, CNC ROUTER MACHINE

ATC CNC ROUTER, CNC ROUTER MACHINE1325 Woodworking 4×8 CNC Router With ATC

ATC CNC ROUTER, CNC ROUTER MACHINE

ATC CNC ROUTER, CNC ROUTER MACHINE1325 Woodworking CNC Router Wood Engraving Machine

4 AXIS CNC ROUTER, CNC WOOD ROUTER

4 AXIS CNC ROUTER, CNC WOOD ROUTER4 Axis CNC Router with automatic tool changer

ATC CNC ROUTER, CNC ROUTER MACHINE

ATC CNC ROUTER, CNC ROUTER MACHINECNC Router Spindle ATC Carving On Wood

ATC CNC ROUTER, CNC ROUTER MACHINE

ATC CNC ROUTER, CNC ROUTER MACHINEEconomical 4×8 Linear ATC CNC Router G6

- ATC CNC ROUTER, CNC ROUTER MACHINE

Wood Carving ATC CNC Router Machine 1325

CNC wood router 4×8 is the most popular model in all our cnc routing machines, generally refers to a router with 4 by 8 feet (4’x8′ or 48″x96″) working size. This wood CNC Router is built with one single head and vacuum-sorb working table as well. The electric spindle adopts liquid-cooled one, which is much better for a long time continuous carving or milling. The working table is two in one design, can fix material by vac-sorb as well as by clamp accordingly to your production requirement. The unique industrial plug design makes the electrical components of the wood router more stable and durable. This 4×8 cnc machine is ideal for universal application and beginners. So we can say, it is one of the best entry-level wood routers.

How Many Types of Wood CNC Machines?

What types of wood CNC machines are right for your business? Review the most common types of popular CNC machines for woodworking.

Types based on table sizes (work area): 2×3 table tops, 2×4 table tops, 4×4 table tops, 4×6 table tops, 4×8 table tops, 5×10 table tops, 6×12 table tops.

Types based on applications: Home types, Desktop types, 3D types, Hobby types, Commercial types, Industrial types. Types based on axis: 5 axis CNC machines for woodworking, 4 axis wood CNC routers, 4th axis (rotary axis) CNC woodworking routers, 3 axis CNC wood routers.

4×8 CNC Wood Router Machine Applications

1. Furniture Making: Cabinets, office furniture, home furniture, chairs, tables, doors, and windows.

2. Woodworking: Computer tables, game cabinets, voice box, sewing machines table, music instruments, wood balusters spindles, table legs, and some cylinder woodworking projects.

3. Decorations: MDF, organic glass, artificial stone, PVC, acrylic, plastic and soft metals such as aluminum, copper, brass cutting and milling.

4. Industrial Manufacturing: Sign making, plastic chemical components, insulation part, bowling tracks, inner body of car, stairs, epoxy resin, anti bate board, PCB, ABS, PE, PP, and other carbon mixed compounds.

Whether you are looking for an industrial 4X8 CNC cabinets router furniture machine with an 8-hour shift or a private use cheap CNC router, ABS-1325 4×8 table must be a good choice. The 4×8 CNC router kit is designed for plywood or other materials quickly and accurately with a stepper motor and driver. T-slot CNC Router Table or vacuum table for 4 x 8 cnc router table cheap also depends on your choice. It’s all guarantees the stability of carving or cutting the material. The wood CNC router 1325 cutting materials and shapes are spread across wide industries. It can be said that the 4 x 8 CNC router kit price is absolutely reasonable and the CNC router 1325 is absolutely cost-effective. If you want to know other CNC wood routers, Such as the 4×4 CNC router machine which is cheaper. Just contact us, we will apply to you ASAP!